New video on YouTube: Two-Sided Machining: 6 Cross Holes, Axial Grooving, Face Turning (C+Y Axis)

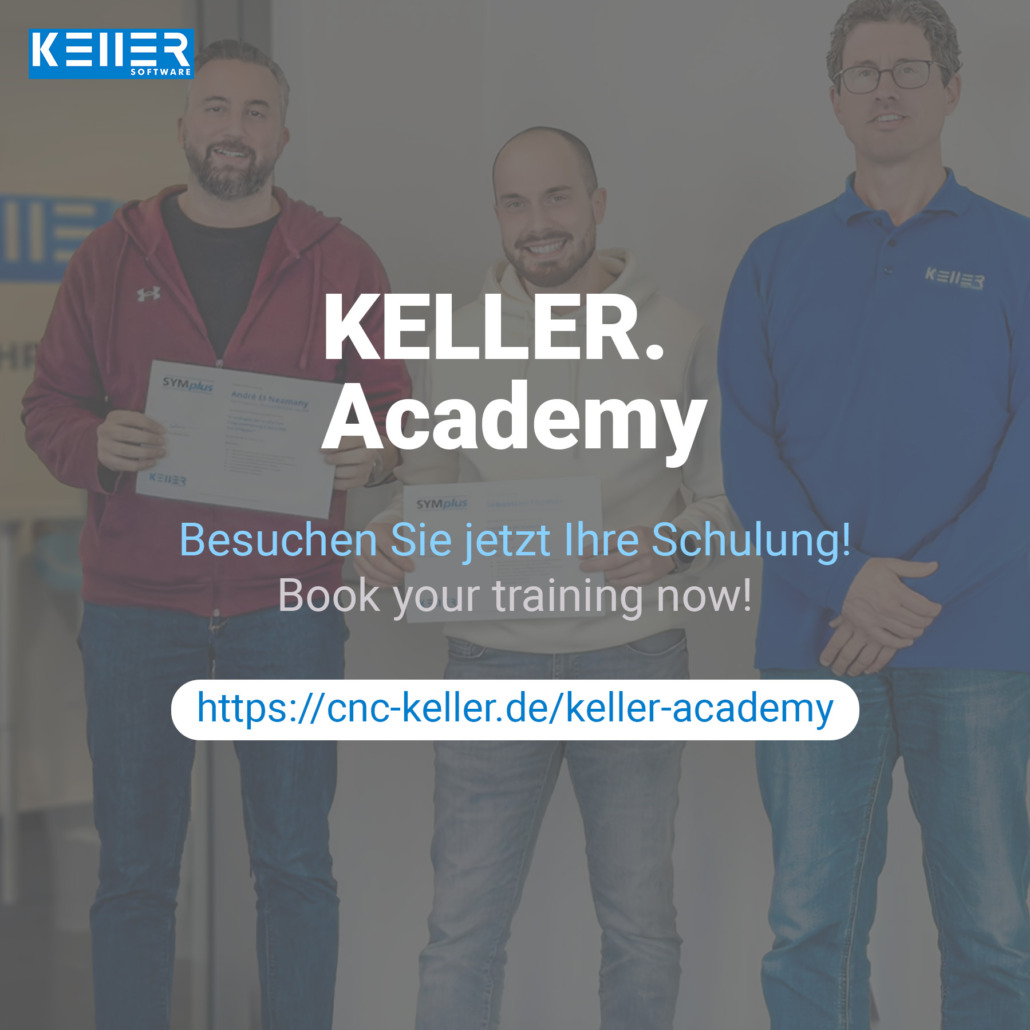

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 3 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Driven Tools” could look like in reality.

This task includes:

- Axial grooving in Z direction (Grooving cycle G88)

- External threading

- 2 radial grooves (G86)

- 6 cross holes

- Two-sided turning

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: End face machining with virtual Y-axis (G15 G17 IP3) (C+Y Axis)

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 2 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Driven Tools” could look like in reality.

This task includes:

- Facing, roughing, finishing

- End face machining with virtual Y-axis

- Thread undercut according to DIN standard 76

- Metric threads (2 mm pitch)

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

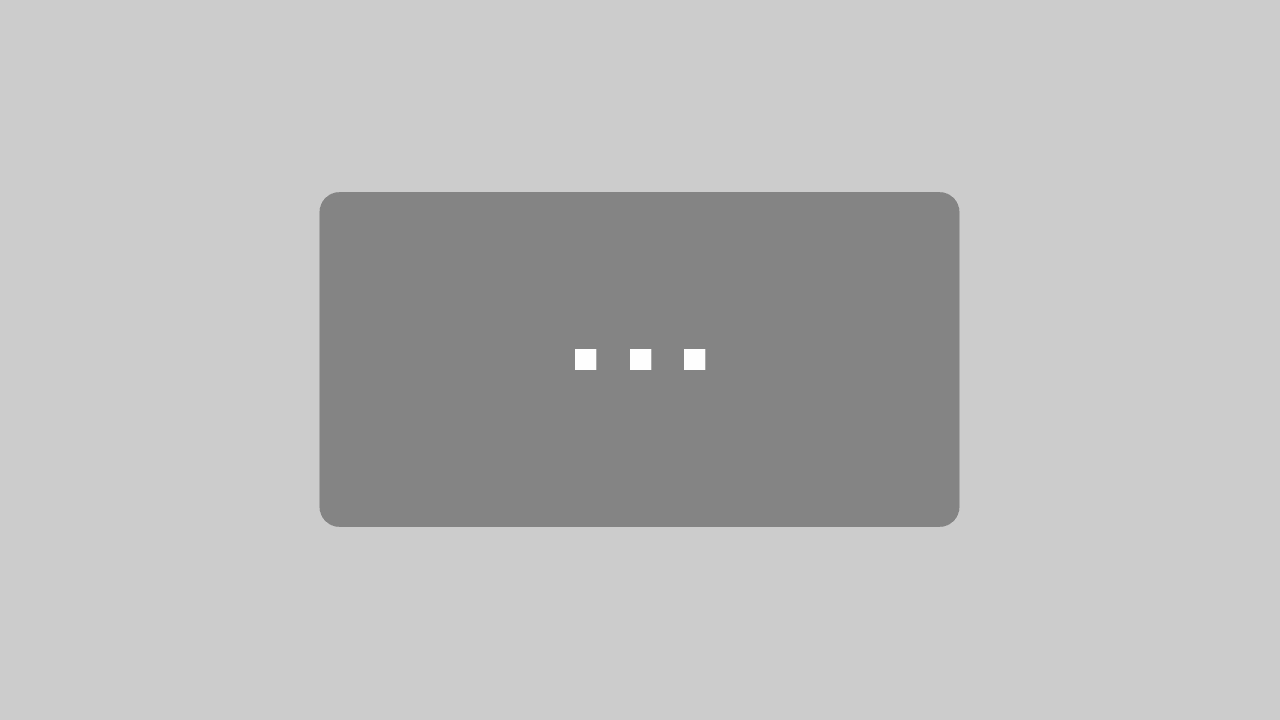

Successful KELLER.Academy Course with the RWTH Aachen University

New knowledge, new opportunities! Two users from the Zentral-Werkstatt der FRE (Department for Raw Materials and Waste Management) at RWTH Aachen University gained exciting insights into the basics of graphical programming (CAD/CAM) with SYMplus™ at our KELLER.Academy.

Congratulations to Mr. Thomas and Mr. El-Neamany on successfully completing the KELLER.Academy course! Thank you for your trust and for the great time together.

Would you also like to take your career to the next level?

Discover the wide range of training opportunities at the KELLER.Academy now and invest in your future: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

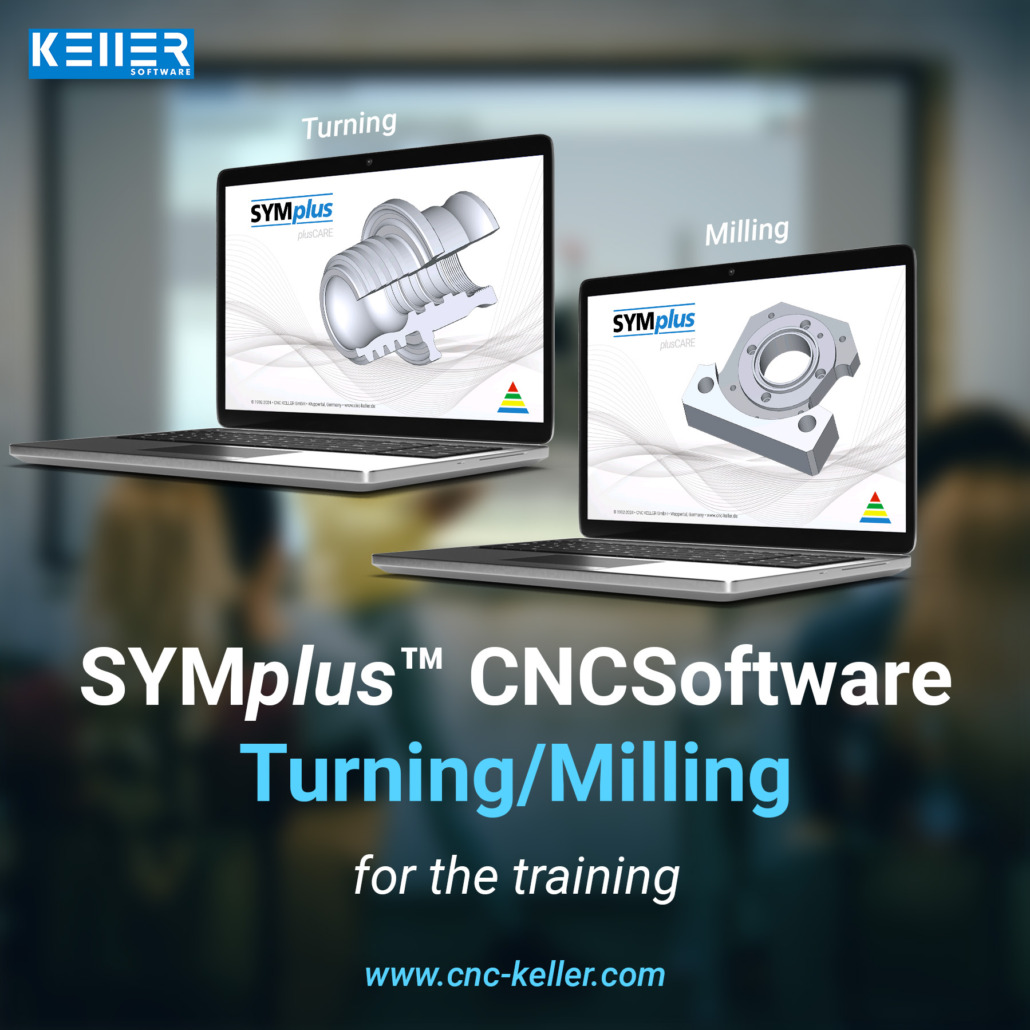

No time for good CNC education? (Learn CNC with SYMplus™)

As a teacher in the CNC sector, you’re constantly under time pressure to keep everything running smoothly. But with our CNC software SYMplus™, a significant part of that burden is lifted from your shoulders. Now you can offer your trainees high-quality training without having to constantly rush.

SYMplus™ supports you in teaching complex content so that you can concentrate on the essentials: preparing your trainees for the future. This makes your work more efficient and ensures the long-term success of your trainees.

- Discover how SYMplus™ can make your work easier and secure your trainees learning success. Click here for more information: symplus-for-cnc-training

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

NETZSCH Group at the KELLER.Academy (Driven Tools, Level Swivel, PAL standard 2020)

We had a fantastic time at the KELLER.Academy! In 1.5 days, our participant explored driven tools, mastered the level swivel, and learned all about the changes brought by the 2020 reform at PAL.

Congratulations to Mr. Müller from NETZSCH Feinmahltechnik GmbH (NETZSCH Group) for successfully completing the KELLER.Academy course! Thank you for your participation!

The photos showcase results from the course: workpieces with 3+2 axes and C and Y axis.

Would you also like to take your career to the next level?

Discover the wide range of training opportunities at the KELLER.Academy now and invest in your future: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

The future of CNC machining starts in the classroom

The future of CNC professionals is in your hands! By using modern CNC training software like SYMplus™, you empower your students with the knowledge they need to thrive in a rapidly changing industry. With over 40 years of experience and insights from CNC experts, trainers, and educators, SYMplus™ is designed to meet the needs of today’s vocational training.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Axial Milling with Driven Tool: Main Spindle as Rotary Axis (C+Y Axis)

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 1 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Driven Tools” could look like in reality.

This task includes:

- Face turning

- Longitudinal turning

- Axial milling with driven tool

- Main spindle as rotary positioning axis

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Milling a Pyramid: Swiveling around the AM and BM Axes (3+2 Axes)

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 10 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Multi-Sided Machining” could look like in reality.

This task includes:

- Swivel AM, BM, -AM, -BM

- Face milling

- Engraving numbers

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Cylinder Machining: 90-Degree Swivel, Milling, Thread Cutting (3+2 Axes)

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 9 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Multi-Sided Machining” could look like in reality.

This task includes:

- 90-degree swivel and shoulder milling

- 180-degree C-axis rotation

- 30-degree chamfer milling

- T-slot cutter

- Drilling and threading

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Pocket cycles, Groove cycles and Drilling patterns (CNC Milling)

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 3 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020” could look like in reality.

This task includes:

- Pocket cycles (G73, G72)

- Groove cycles (G74, G75)

- Drilling patterns (G81 with G76, G77)

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!