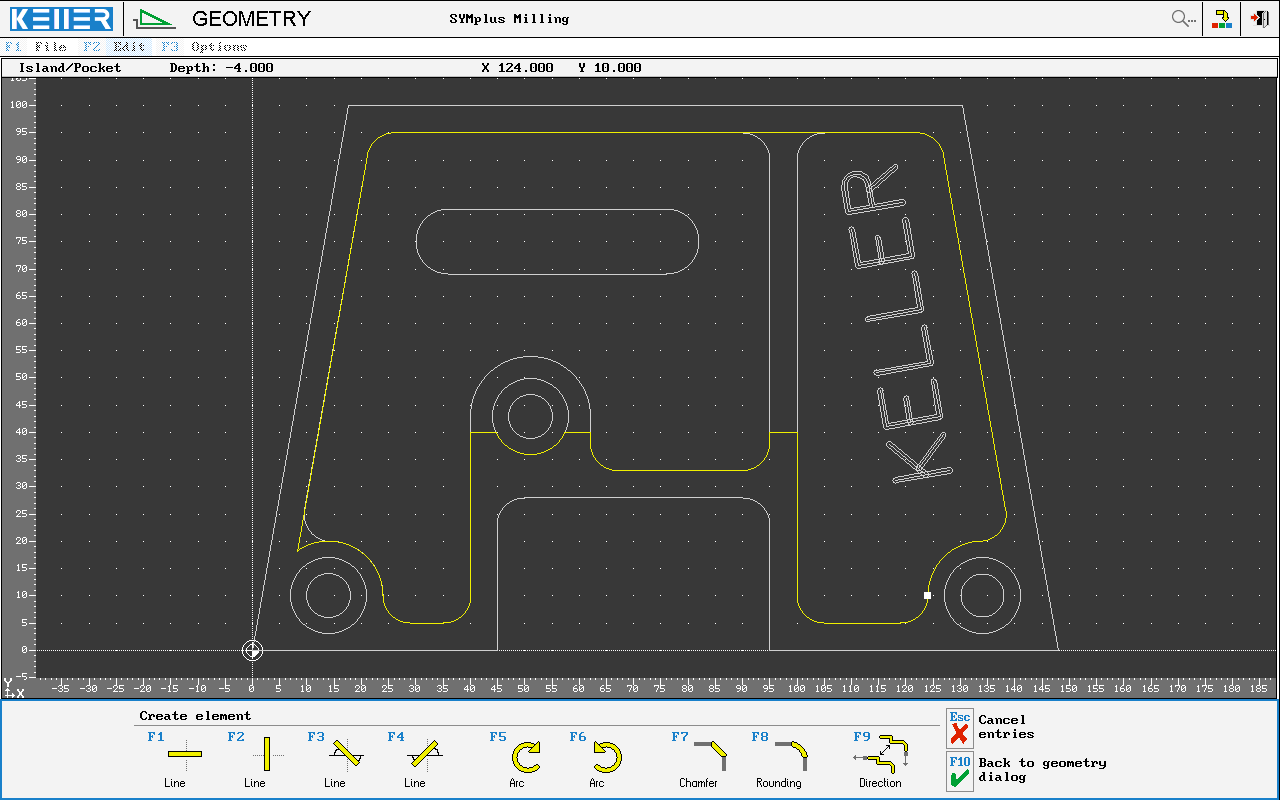

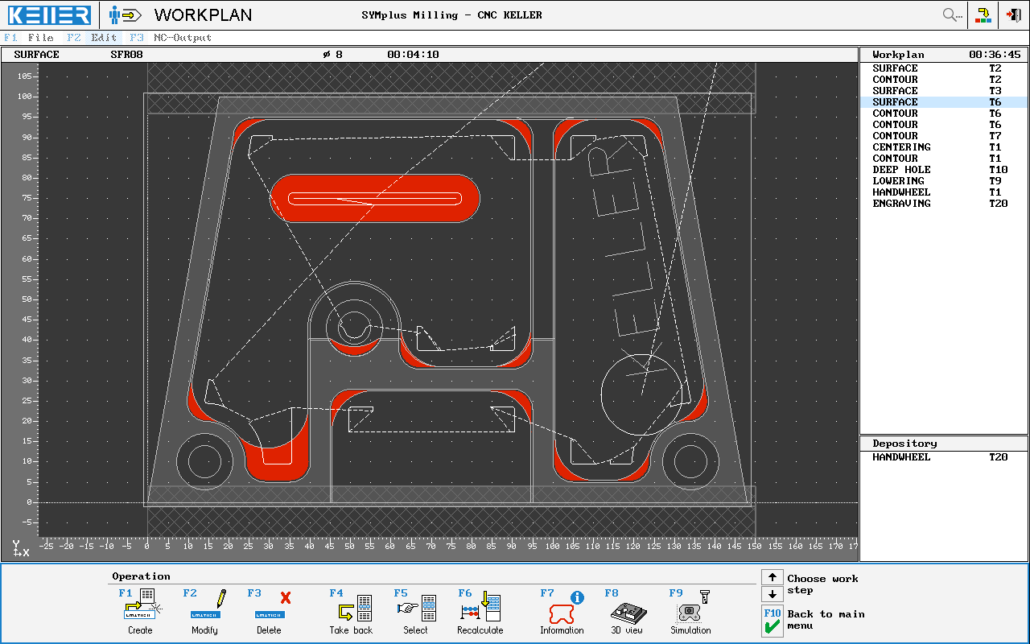

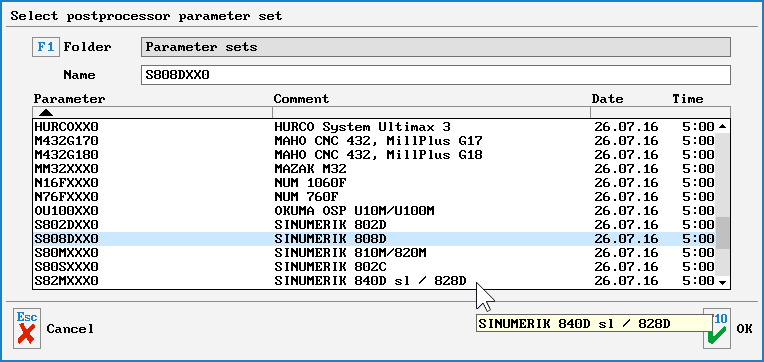

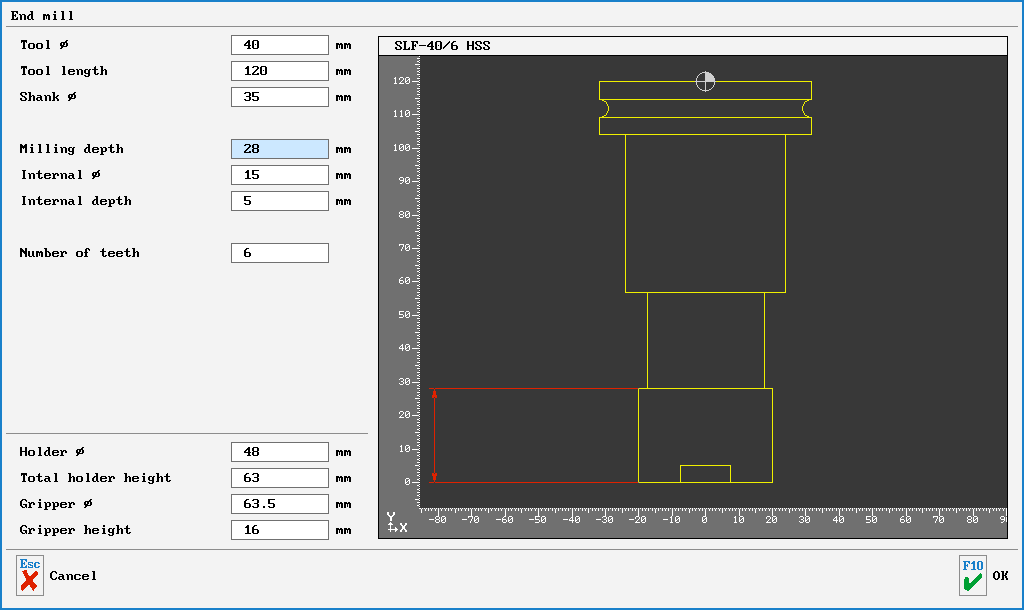

SYMplus™ CNC Software

for production

Modular CNC software for highest demands

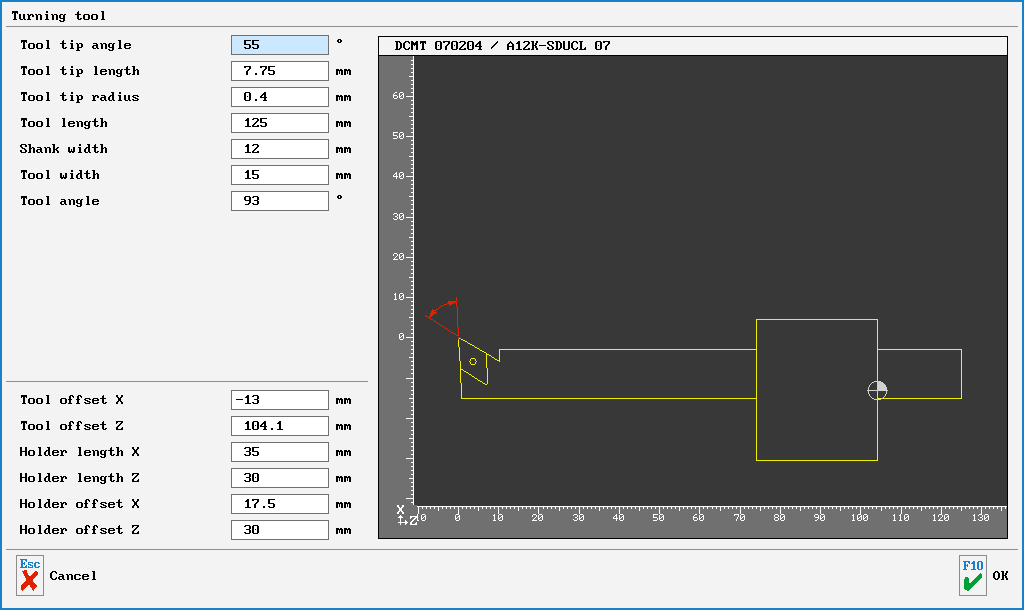

With SYMplus™ turning and SYMplus™ milling, your production becomes even more effective, because the graphic interface, the powerful contour computer and time-saving production strategies support you in generating an optimal NC program quickly and easily … regardless of the control!