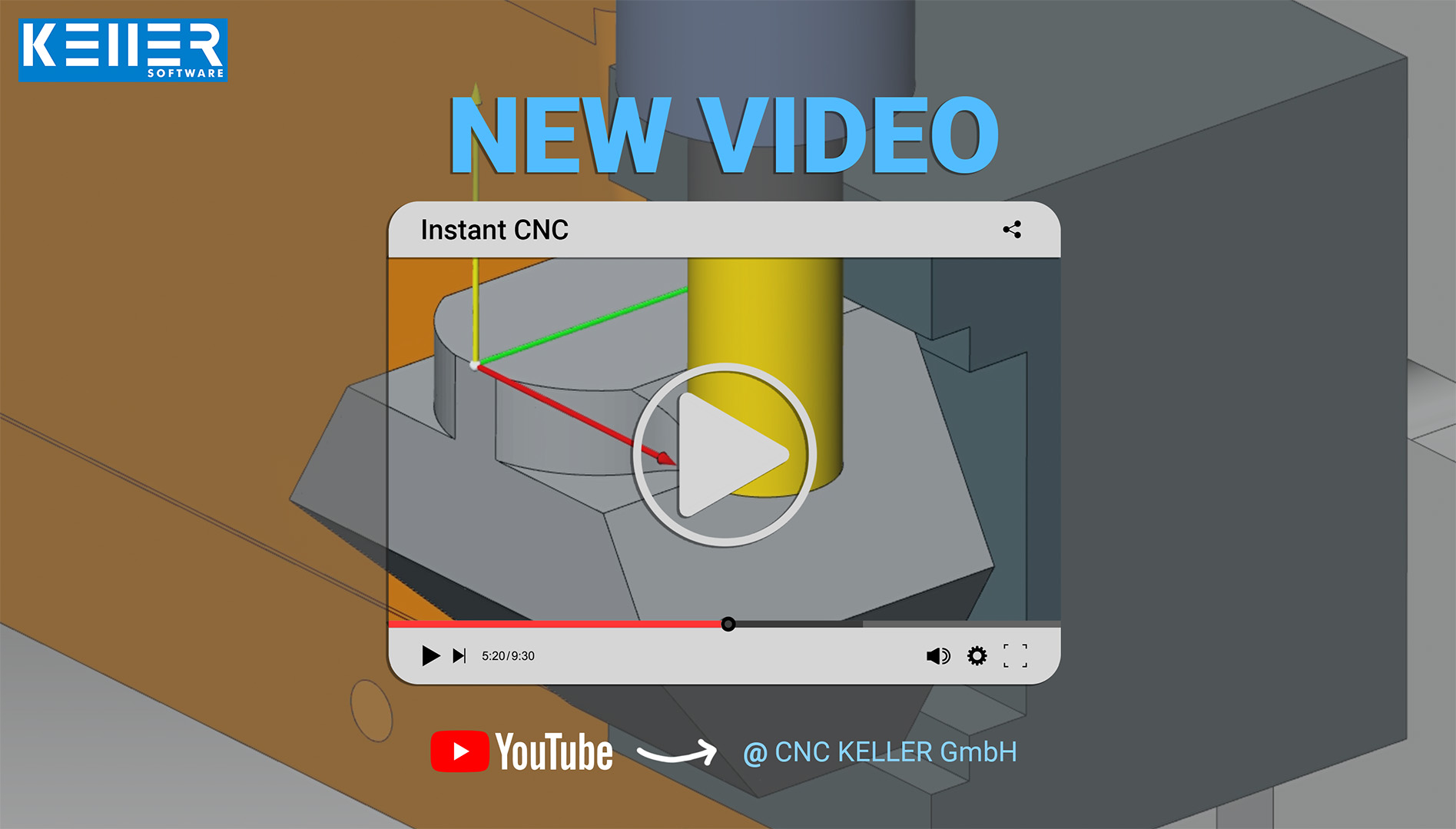

New video on YouTube: Shift Through All Gears! Programming Gear Shifting in CNC Milling

Can you shift through all the gears? We’ll show you how it’s done—from reverse all the way to fifth gear. So, buckle up and let’s get started!

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Newsletter September 2024

Prevent Data Loss : Key Tips for KELLER Users.

Summer is slowly coming to an end and the new training year has begun. Many trainees are now entering the world of CNC, while others are preparing for their final exams. No matter which stage you are at, we are here for you: with the SYMplus™ workbooks, the SYMplus™ Student License or our YouTube video series “Instant CNC”. In these videos, we simulate the CHRISTIANI exercises — an excellent opportunity to freshen up your knowledge, even for experienced users!

Speaking of “freshening up your knowledge”: A few weeks ago, a customer contacted us because he had lost all his important “KELLER” data when he bought a new computer — tools, work plans, NC programs, everything was gone. And why? Because he had only saved his data on the old computer. Fortunately, we were able to help him transfer the data to the new computer before the old one was disposed of.

To avoid such problems, we recommend that you backup your data regularly. If you need assistance on the subject of “data backup”, our support team will, of course, be happy to help to advise you. You can simply give us a call (0202 – 40400) or e-mail us.

But where exactly do you find your “KELLER” data (the “user data” — as we call it) on your computer? Here is a brief guide:

Where can you find your user data (“KELLER” data) on your computer?

By default, your user data is stored in a specific folder on your computer. Here’s how to find this folder:

1. Open “File Explorer” (this is the program you use to browse files and folders on your computer).

2. Go to “This PC” or “Computer”.

3. Double-click on the drive C (C is normally the main drive of your computer).

4. Open the “Users” folder.

5. Go to your user name (this is the name of your account on the computer).

6. Open the “AppData” folder. If you do not see this, you may need to look at hidden files and folders. You can do this in the “View” options in File Explorer or customize it in the “Appearance” category in your computer’s Control Panel (may differ slightly depending on your version of Windows).

7. In “AppData”, open the “Roaming” folder.

8. And then the “KELLER” folder.

Within the KELLER folder there are two further subfolders, depending on what type of machine you are using:

For turning machines: open the “KELLERplusDE” folder and then the “DATASD” subfolder.

For milling machines: Open the folder “KELLERplusFE” and then the subfolder “DATASF”.

For detailed instructions on how to find the storage locations of your user data, please read our support article:

›Where do I find the user data?‹

We trust that this information will help you and make your work easier. If you have any questions, please don’t hesitate to contact our support team.

Wish you a nice day and best regards.

Your KELLER.Software Team

Have you already installed SYMplus™ Update 66?

SYMplus™ CNC software Update 66 is now available for installation for all plusCARE™ customers. With a wide range of improvements and optimised functions, we want to ensure that you can work with the software as smoothly as never before.

Guide to Update SYMplus™:

›How to install an update‹

Next Appointments in the KELLER.Academy:

Basics of graphical programming (CAD/CAM) with SYMplus™

- 24.-25. October 2024

Basic DIN/PAL programming with SYMplus™

- 21.-22. November 2024

Driven tools, level swivel and reform PAL2020

- 10.-11. October 2024

- 05.-06. December 2024

Exam preparation PAL

- 07.-08. November 2024

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Driven tools, level swivel and reform PAL2020 (KELLER.Academy)

It’s (almost) the end of the summer months, and we had the pleasure of welcoming Mr Rosenkranz from Grünewald Feinmaschinenbau GmbH & Co. KG from Grävenwiesbach (Hesse) to the KELLER.Academy! In an intensive one-to-one course, he was able to deepen his knowledge of driven tools, plane swivelling and the PAL2020 reform.

Thank you very much for the great time and the exciting 1.5 days! It was a pleasure to have you in Wuppertal – we look forward to seeing you again!

Would you also like to take your career to the next level? Discover the wide range of training opportunities at the #KELLERAcademy now and invest in your future:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

CNC software for CNC training (cutting machine operator)

The new generation is ready!

Each trainee brings their own personality and energy to the table. With SYMplus CNC learning software, everyone is well equipped, whether they are just starting their training or preparing for the exam. The ease of use and the ability to work independently makes SYMplus the ideal software for practical preparation.

- Find out more: https://cnc-keller.com/symplus-cnc-software/pal-software/

The KELLER.Software team wishes everyone a great start into the 2024/2025 training year and lots of success – but above all lots of fun learning your trade!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: From Rough Milling Cutters to Engraving: CNC machining made easy (3+2 Axes)

- Take a look: https://youtu.be/nynhlbjqnIM

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 8 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Multi-Sided Machining” could look like in reality.

This task includes:

- 63 roughing cutter

- Contour pocket cycle G34 to G39

- Engraving: Numbers and letters

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

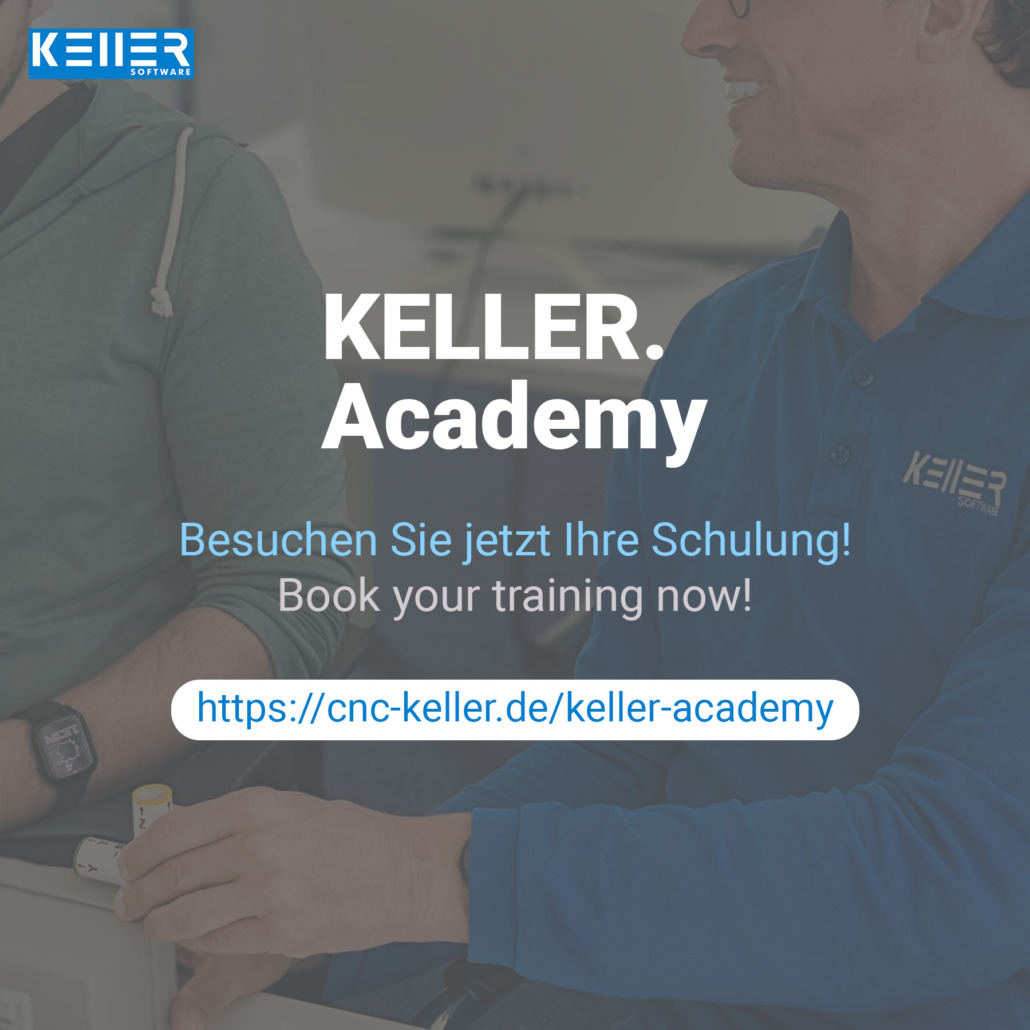

Training Year 2024/2025 (for Cutting Machine Operators and similar professions)

Let’s kick off the new training year!

The start of the new training year is just around the corner! Whether you are just starting out in the CNC world or already have experience, the KELLER.Software team wishes you a successful start!

The right tool is just as important for learning as it is for the machine. Our SYMplus™ workbooks offer you the perfect support:

- Clear structure: from the basics to PAL exam preparation (turning and milling) to control-specific specialist training and CAD/CAM.

- Practical tasks: With lots of exercises to apply what you have learned, you will consolidate your knowledge and gain practical experience.

- Independent learning: You can organize your learning flexibly with the workbooks.

Get your SYMplus™ workbooks now and make this year your year: https://cnc-keller.com/symplus-support/workbooks/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

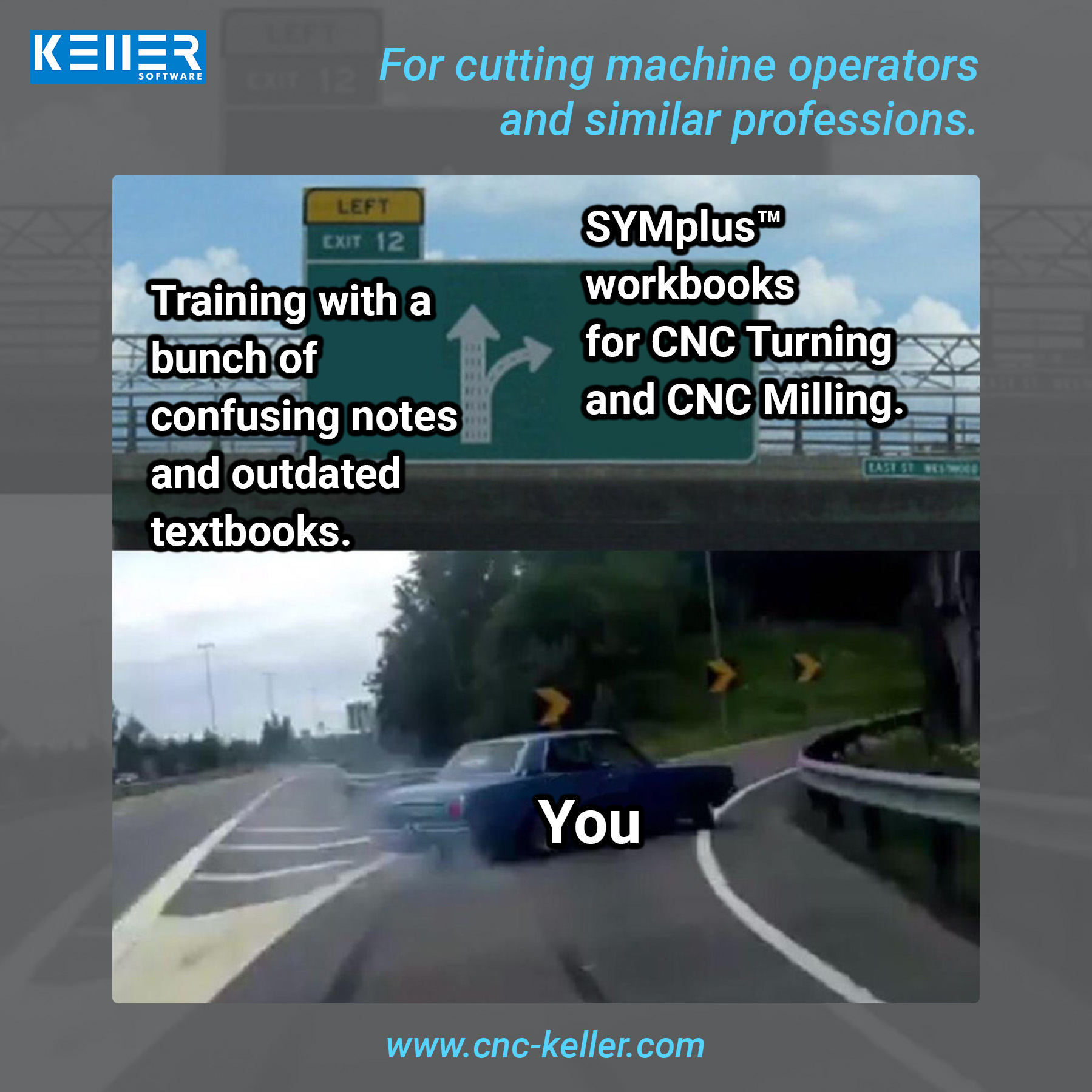

New video on YouTube: Precise CNC Machining: Swiveling, Milling, Drilling (Hexagonal Raw Part, 3+2 Axes)

- Take a look: https://youtu.be/pa0OMEIlfaU

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 7 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Multi-Sided Machining” could look like in reality.

This task includes:

- Swiveling by 45 and 90 Degrees

- Hexagonal Raw Part

- Cutter Ø63

- Roughing and Finishing

- 3 Drill Holes

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

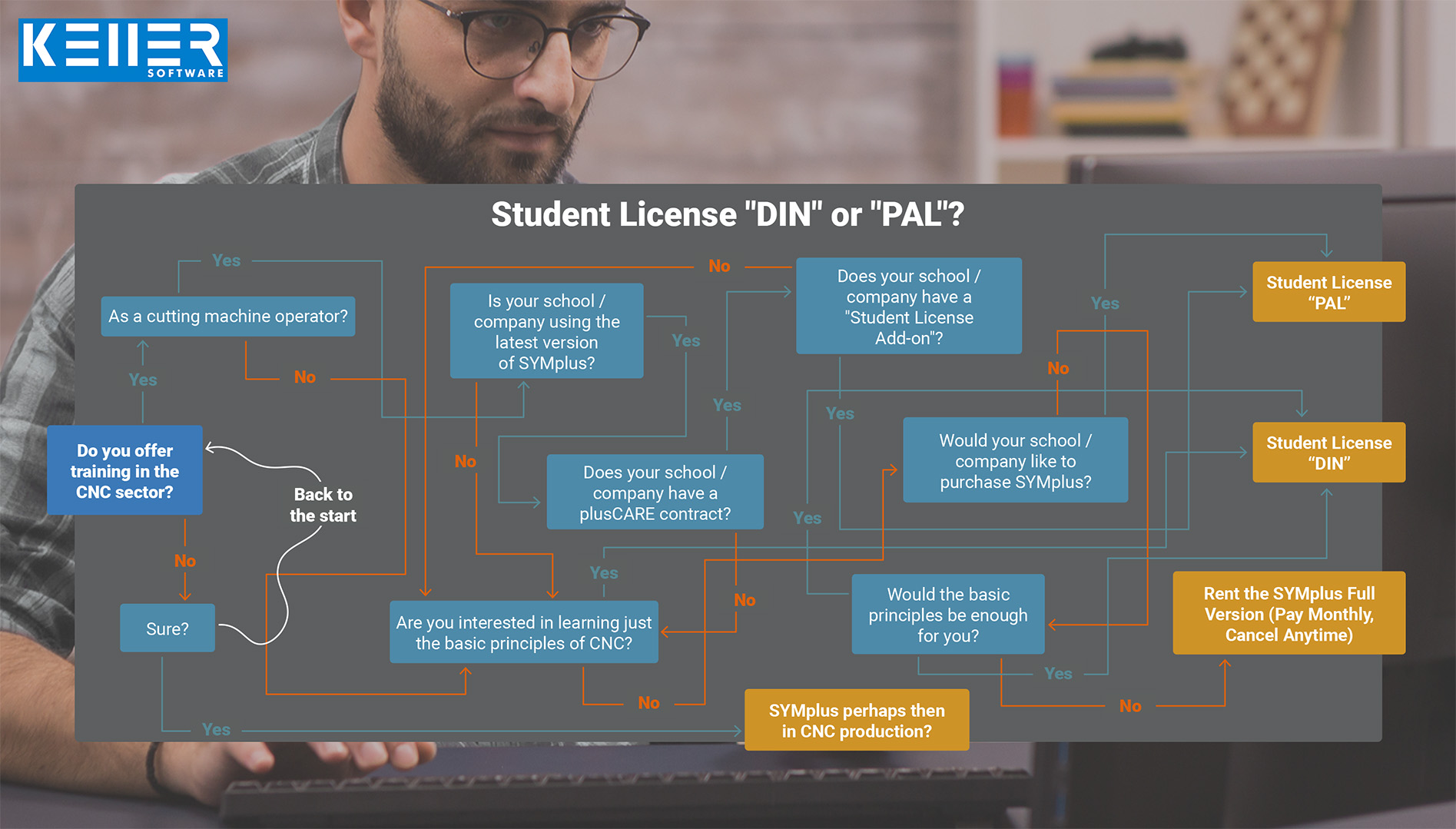

Student License “DIN” or “PAL”?

Student License “DIN” or “PAL”? A question we hear from time to time. This graphic might help you make the right choice!

- To acquire SYMplus license: https://cnc-keller.com/buy-symplus/

What is the latest version of SYMplus?

https://cnc-keller.com/symplus-support/new-features-optimizations/

What is plusCARE?

https://cnc-keller.com/symplus-support/pluscare/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Milling Tower with Battlements: 50 mm Roughing Cutter, Circular Tenon and Pocket (3+2 Axes)

- Take a look: https://youtu.be/2Oqes0JiCDc

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 6 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Multi-Sided Machining” could look like in reality.

This task includes:

- Zero Offset in X and Z

- 10-degree Swivel

- 50 mm Roughing Cutter

- Circular Tenon

- Circular Pocket

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Kick-start your CNC career with the “DIN” student license from SYMplus

Would you like to learn the CNC basics and prepare yourself for a career as a machinist? Then the “DIN” student license of our CNC training software “SYMplus” is just made for you:

- The “DIN” student license from SYMplus lays the foundation for your successful career as a machinist. It expands your knowledge and prepares you specifically for the PAL exams.

- Rent the software easily: Students can easily rent the “DIN” license of SYMplus for a specific period (14 days to 1 year) themselves (at low cost) and cancel it at any time.

- Immerse yourself in CNC programming: With the SYMplus “Interactive Learning” module, you will receive a comprehensive introduction in accordance with DIN66025 (includes the PAL basic commands) and deepen your knowledge of important geometry functions such as chamfers, fillets, lengths and angles.

- Practical application: Program according to your own drawings in the simulator and check your work with the 2D and 3D simulation.

Start your CNC training with SYMplus now: *Rent SYMplus: click here*

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!