Back at the KELLER.Academy – this time with a focus on DIN/PAL!

For the second time, we had the pleasure of welcoming Mr. Grodfeld from Röhm GmbH. After attending our CAD/CAM course, he now took part in the “Basics of DIN/PAL Programming with SYMplus™” course.

Thank you for your continued interest and trust – maybe we’ll see you again soon for a third course?

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

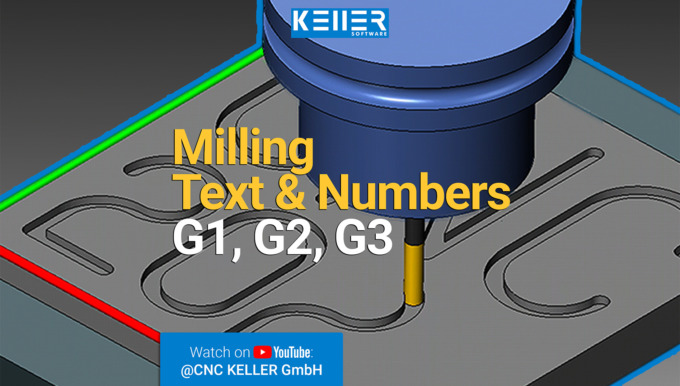

Milling Text and Numbers with G1, G2, G3: G-Code (PAL) Basics (Video)

In this video, we guide you step by step through Task 1 from the Christiani task collection “CNC Milling Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect in the video:

✅ Milling text and numbers using:

✅ G1 (straight line)

✅ G2 (circular arc clockwise)

✅ G3 (circular arc counterclockwise)

Who is this video for?

Perfect for CNC programmers, machinists, and instructors looking to improve their PAL G-code programming skills for CNC milling.

Subscribe to our channel to not miss out on more tutorials and tips:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Graphic programming made easy – with the KELLER.Academy!

Graphic programming made easy – with SYMplus™ and the KELLER.Academy!

In a compact one-on-one training session, Mr. Grodfeld from Röhm GmbH (a leading manufacturer in methacrylate chemistry) dived straight into the world of graphic programming: creating workpieces based on drawings or CAD files – practical, easy to understand, and ready for real-world use.

Thank you for your trust and active participation!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

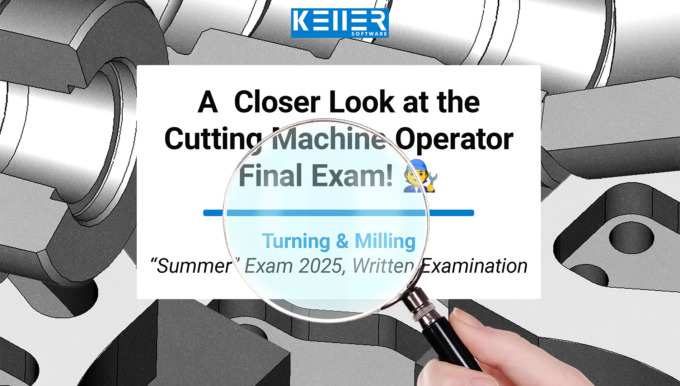

Exam Cutting Machine Operator (Summer 2025 Turning/Milling)

Cutting Machine Operator Exam Summer 2025 – done!

The Cutting Machine Operator Exam is a specialized certification (IHK) in Germany that assesses both practical and theoretical skills in CNC machining.

Want to take a closer look at the exam?

On our YouTube channel, you can find 3D simulations of the workpieces (turning & milling) from the written part of this exam – including brief explanations of the individual steps. This gives you a clear idea of what the parts look like and what was expected in the exam.

Please note: This exam and the related content are specific to the German vocational training system and may differ from similar certifications in other countries.

Subscribe to our YouTube channel for more practical CNC content:

Turning:

- In turning, the focus was on several typical machining operations, including facing and longitudinal turning of the outer contour, roughing and finishing of the inner contour, as well as threading an internal thread M36 with a 1.5 mm pitch. Additionally, a 24 mm hole was drilled.

Please note: The video are only available in German.

Milling:

- In milling, the focus was on various milling strategies, including an outer contour with multiple tools, an angled surface, a slot with a circular arc, and a complex inner contour. Additionally, drilling operations and an M6 thread were included.

Please note: The video are only available in German.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Radial Grooving Cycle G86: All key parameters explained (Video)

In this video, we guide you step by step through Task 7 from the Christiani task collection “CNC Turning Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect in the video:

✅ Radial Grooving with the 2020 revised G86 Grooving Cycle

✅ Three practical examples for programming Grooves

✅ Targeted use of new parameters: LE, EP, RO/LO, AS/AE, H14 …

Who is this video for?

Perfect for CNC programmers, machinists, and instructors looking to improve their PAL G-code programming skills for CNC turning.

Subscribe to our channel to not miss out on more tutorials and tips:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Ready for the CNC Programming with KELLER.Academy!

In just one and a half days, the participants dived deep into the fundamentals of CNC (PAL) programming with SYMplus™ – gaining valuable knowledge to apply in their teaching/work routines.

Thank you for your active participation and the insightful exchanges!

Course participants:

🔹 Gutmann GmbH

🔹 Paul-Weber-Schule (Vocational Training Center Homburg)

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Mill a Star-Shaped Contour with G2/G3 + Ball End Mill (Video)

In this video, we guide you step by step through Task 8 from the Christiani task collection “CNC Milling Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect in the video:

✅ Program a star-shaped contour with G2/G3

✅ Ball end mill/Radius mill in action: Precise profiling/finishing

✅ Practical application of G-code for various milling techniques

Who is this video for?

Perfect for CNC programmers, machinists, and instructors looking to improve their PAL G-code programming skills for CNC milling.

Subscribe to our channel to not miss out on more tutorials and tips:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

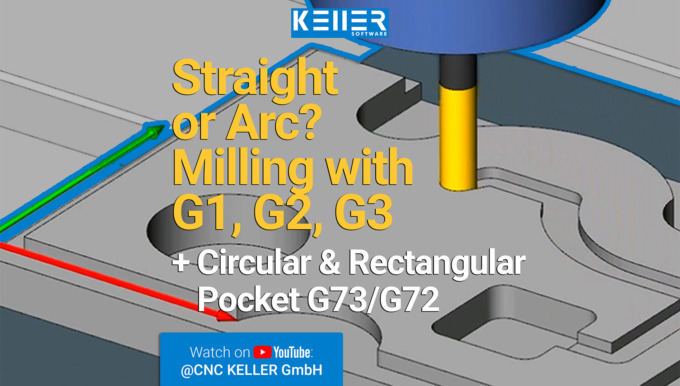

Straight or Arc? Milling with G1, G2, G3 (Video)

In this video, we guide you step by step through Task 7 from the Christiani task collection “CNC Milling Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect in the video:

✅ Outer contour with G1, G2, G3 and Cutter Compensation G41

✅ Programming circular and rectangular pockets with G72 and G73

✅ Milling freeform paths precisely with combinations of G1, G2, and G3

Who is this video for?

Perfect for CNC programmers, machinists, and instructors looking to improve their PAL G-code programming skills for CNC milling.

Subscribe to our channel to not miss out on more tutorials and tips:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

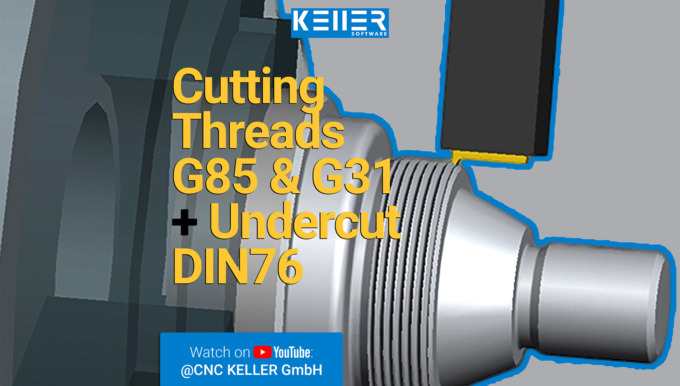

Internal Thread G85 & G31 + Undercut DIN76, PAL G-Code (Video)

In this video, we guide you step by step through Task 6 from the Christiani task collection “CNC Turning Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect in the video:

✅ Thread programming made easy with G31

✅ Clean undercuts with G85 – DIN 76 compliant

✅ Roughing & finishing cycles – precise and efficient

Who is this video for?

Perfect for CNC programmers, machinists, and instructors looking to improve their G-code programming skills for CNC turning.

Subscribe to our channel to not miss out on more tutorials and tips:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Happy Easter 2025!

Happy Easter from the KELLER.Software team! 🐰

This year, we’ve wrapped up our Easter greetings a little differently: Our apprentice came up with the idea to design an Easter bunny using the geometry module of our CNC software SYMplus™ – completely self-initiated and fully programmed on their own. We were all impressed with the result – and we hope it brings a smile to your face too.

We wish you a joyful Easter, sunny spring days & some relaxing holidays!

- Watch how a simple contour turns step by step into a neat little bunny – fully simulated with our CNC training software SYMplus™.

Subscribe to our channel to not miss out on more videos:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!