New video on YouTube: CNC simulation on the HURON K2X8 FIVE: Machine axes and milling techniques (CNC Milling, 3+2 Axes)

- Take a look: https://youtu.be/3Z6U6kN24Qk

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 5 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Multi-Sided Machining” could look like in reality.

This task includes:

- X-, Y- and Z-axis

- Swivel

- Lateral groove with a T-slot cutter

- Roughing and finishing

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Olympia, Paris 2024

Happy Olympics to our neighbouring country France!

Did you know that the famous Olympic flag first flew in Antwerp (Belgium) in 1920?

Pierre de Coubertin, an important initiator of the modern Olympic Games and the inventor of the flag, once said of its significance: “The flag is white, with five intertwined rings in blue, yellow, black, green and red. These colours symbolise the union of the five continents.” At a time of nationalism and international tensions, Coubertin set an example of global unity and peace with the five rings we are all familiar with today.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

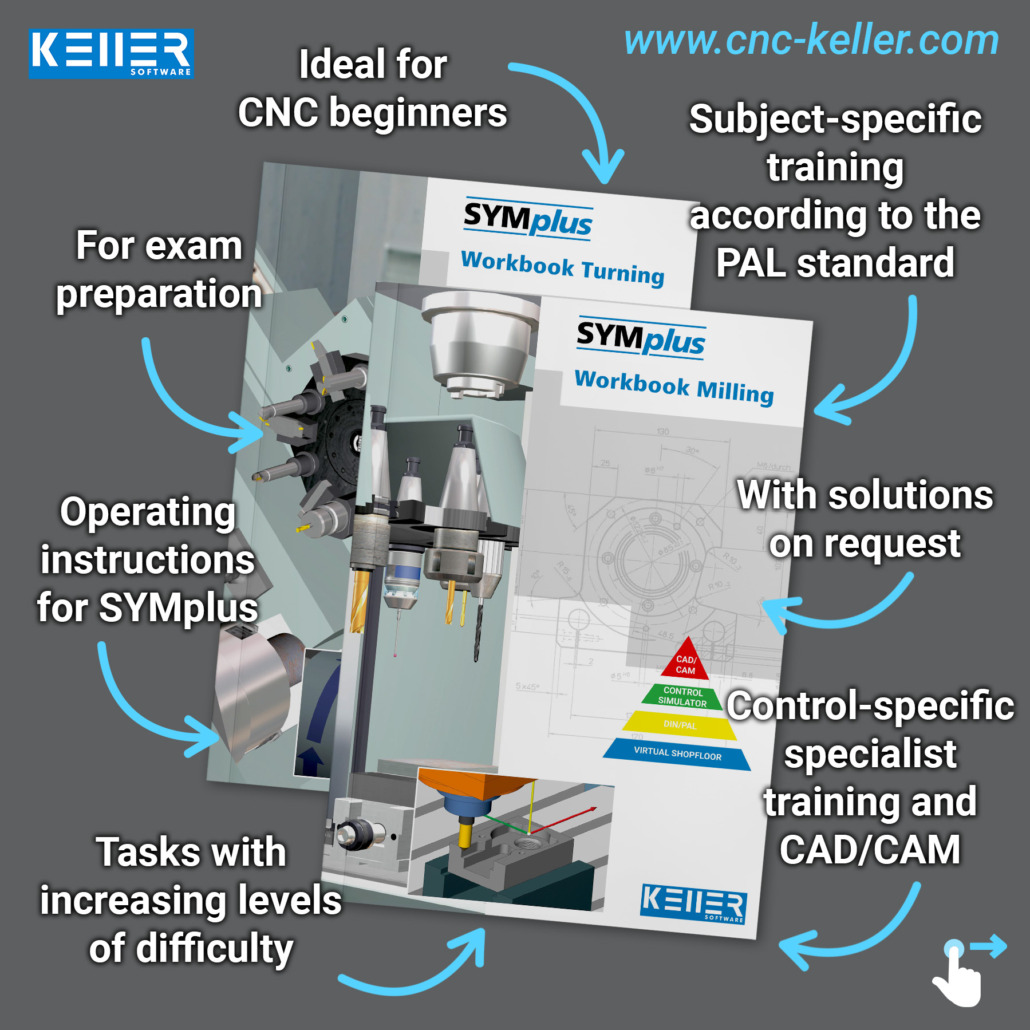

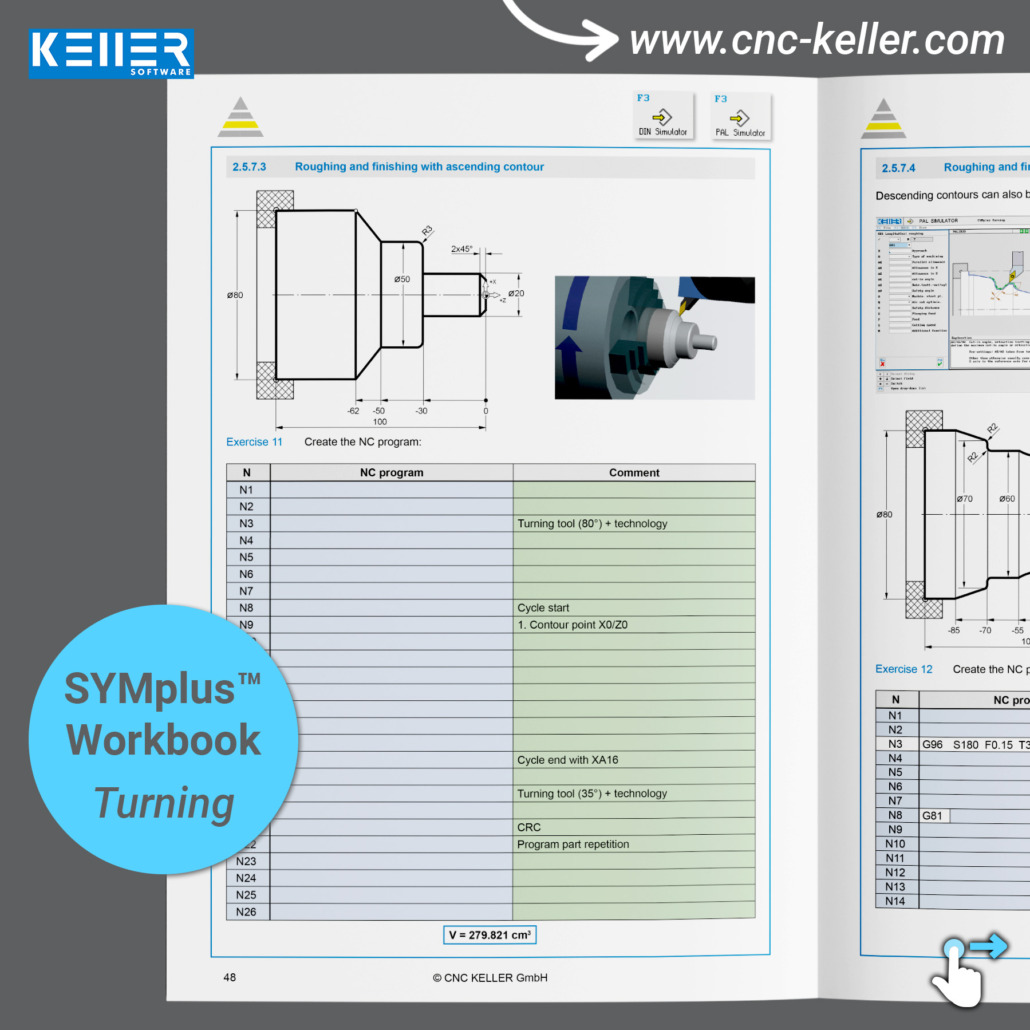

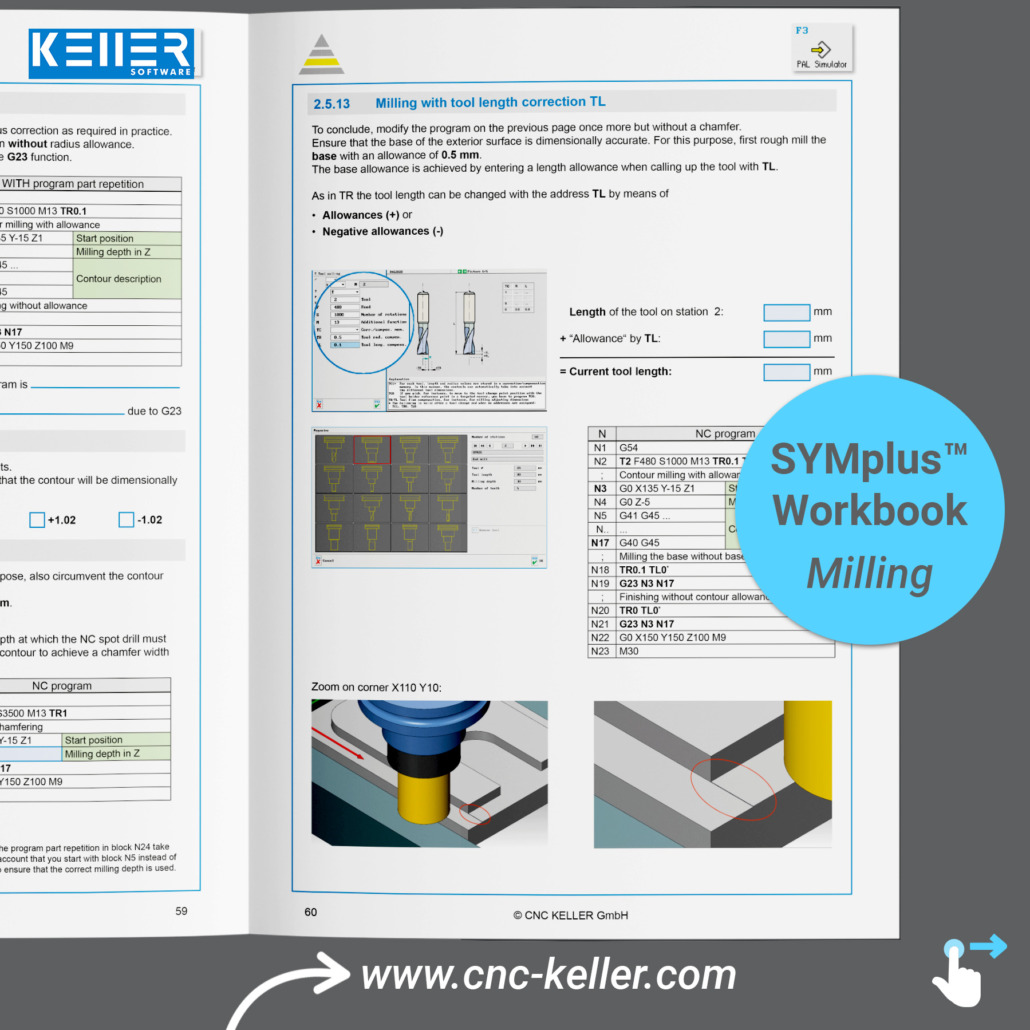

KELLER workbooks for CNC milling and CNC turning

Let’s say you are convinced that our SYMplus™ CNC software can effectively train your trainees. But what happens next? Start the software and simply put the trainees in front of the PCs? That’s one option, but we have a better suggestion:

The KELLER Workbooks!

The KELLER Workbooks are the ideal supplement for an independent CNC training course. With a learning concept based on many years of practical experience and many sample tasks, the booklets allow you to deepen your knowledge step by step. And to top it all off: the solutions to the exercises in the workbooks are also available free of charge on request!

Other advantages of the KELLER workbooks?

- Contents organised by topic

- Tasks with increasing levels of difficulty

- Ideal for CNC beginners and basic training according to DIN

- Targeted exercises for exam preparation (PAL exam)

- Control-specific specialist training and CAD/CAM

- Operating instructions for the SYMplus™ software

Take the next step now and optimise the training of your trainees with the KELLER workbooks and SYMplus™!

More information (and reading samples) at: https://cnc-keller.com/symplus-support/workbooks/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Crash prevention during 90-degree swivel (CNC Milling, 3+2 Axes)

- Take a look: https://youtu.be/Toqn2b_qMcY

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 4 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Multi-Sided Machining” could look like in reality.

This task includes:

- 90-degree swivel

- Workpiece “cuboid”

- Changed axis positions due to swiveling

- Crash risk

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

55 years of the Moon Landing

“The Eagle has landed.”

55 years ago today, on July 20, 1969, humans set foot on the moon for the first time. Every machinist knows how crucial precision work is – and it was precisely this precision that made this historic moment possible for mankind.

That’s why our SYMplus CNC software also incorporates maximum precision. So that the “Eagle” … er, the machining, succeeds!

The KELLER.Software team wishes you a great Saturday, enjoy the summer weather – and the moon (by the way, in Germany, this weekend we have a fittingly full moon!)

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Next Milestone Achieved: KELLER Celebrates 2,000 Followers on YouTube

We are absolutely thrilled: Within just 6 months, we’ve reached the next 1,000 followers on our KELLER YouTube channel. 2,000 people, it’s like we’re a small town full of CNC enthusiasts!

THANK YOU SO MUCH!

– Your KELLER.Software team

- Not a follower yet? You can subscribe to us on YouTube for free using the following link: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Swivel around A axis (rotary axis around X) + Thread milling (3+2 Axes)

- Take a look: https://youtu.be/6VBNvs5sRiI

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 3 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Multi-Sided Machining” could look like in reality.

This task includes:

- Swivel around the A axis

- Thread milling G88

- Center hole for M24x2 thread as circular pocket with Ø12 milling cutter

- Plane swivel G15

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Rent SYMplus™ CNC software for the summer season!

Summer, sun, sunshine – and the new training year for cutting machine operators is just around the corner! But what do you do as a trainer with the trainees while the trade school is closed for the vacations? Or are the trainees just starting their training?

With the user-friendly SYMplus™ CNC software, your trainees can receive a comprehensive introduction to machining technology or refresh their knowledge so that they are well-prepared for the next year of their apprenticeship.

Thanks to practical exercises and an intuitive user interface, trainees can (almost) learn completely independently.

The SYMplus™ rental version is best suited for this: simply rent it for the summer months and get started straight away! Ideal for making the most of the time until the new training year.

- SYMplus™ rent: Click here

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Swivel around B-axis (rotary axis around Y) 3+2 Axes

- Take a look: https://youtu.be/DM2BIbqpqRg

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 2 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Multi-Sided Machining” could look like in reality.

This task includes:

- Swivel around the B-axis:

- 1. Zero offset according to PAL G59

- 2. Rotate/pivot coordinate system according to PAL G15

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

5 year work anniversary at KELLER (Throwback 2019)

Today is a very special #ThrowbackThursday! Our in-house application developer and support expert, Mr. Meißner, is celebrating his 5 year work anniversary this month!

He has been a member of the KELLER team for a total of 8 years: first as a trainee from 2016 to 2019, then as a permanent employee. In the first photo, Mr. Meißner (left) is standing next to our CEO, Mr. Mues, shortly after his successful final exam.

Congratulations and we look forward to many more great years together!

Discover more about our history on our website: https://cnc-keller.com/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!