PRACTICAL TIP – Clever Cutting and Reclamping

October 2021

The plan was quite simple.

Cut a turned part to be machined on both sides from the bar and at the same time programme the second machining side. If the length of the blank is defined to such an extent that at the end, there is enough material to “cut” out of the protective zone for the chuck or the clamping jaws.

However, if you proceed as described, after the “cutting off” step it would result in the half-finished workpiece falling in the simulation as in reality the chip tray or a part catcher. Afterwards, the geometry is no longer available in the working plan for further machining.

But what is the solution then? The following practical tip gives you the answer:

Step 1:

Instead of giving the blank an excessive length, make it only slightly longer than the finished part and assign negative values to the outer and inner values of the protection zone (tool width of the parting line).

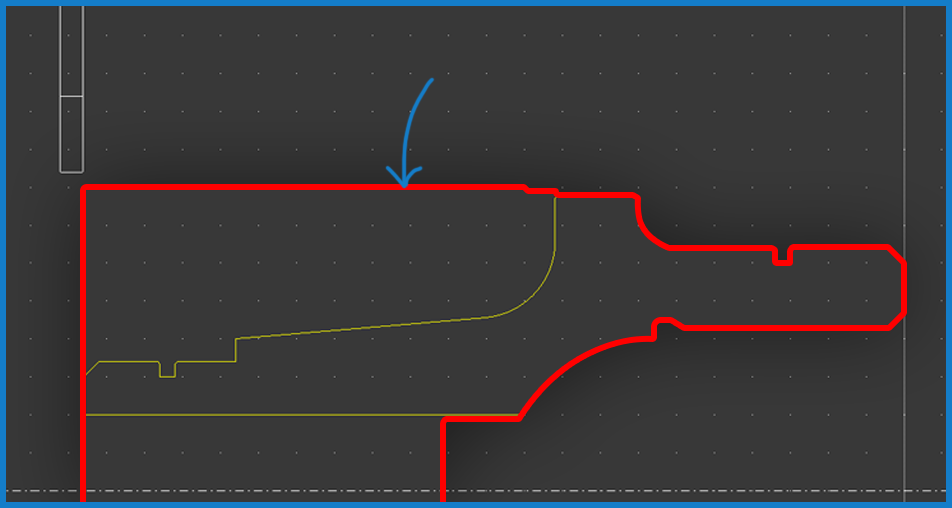

Step 2:

The half-machined workpiece (red lines) then remains in the routing and can be saved in this form via F1 “File” > F7 “Export” > F1 “Workpiece geometry”.

Step 3:

The new blank can then be used for a second working plan.

Step 4:

Under F4 “Clamping” the workpiece is first turned over. Special attention must then be paid to the input field “Shift Z”. In the example, -0.4 must be entered because, in addition to the stock allowance for the second side of 0.2 mm here, the “slug” left by the cutting radius of the parting-off tool must also be taken into account.

Step 5:

The last step is to determine the work steps as usual and as on the first page. Here you benefit from the so-called contour tracking of the software, which recognises where drilling and roughing has already been done from the first page. This becomes visible when creating the work steps by the correspondingly reduced red areas (here for the roughing cut inside).

Now it’s your turn.

Was this tip helpful? Let us know.

You will find more tips in the upcoming newsletters.

You have questions? Contact our experts using the contact form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!