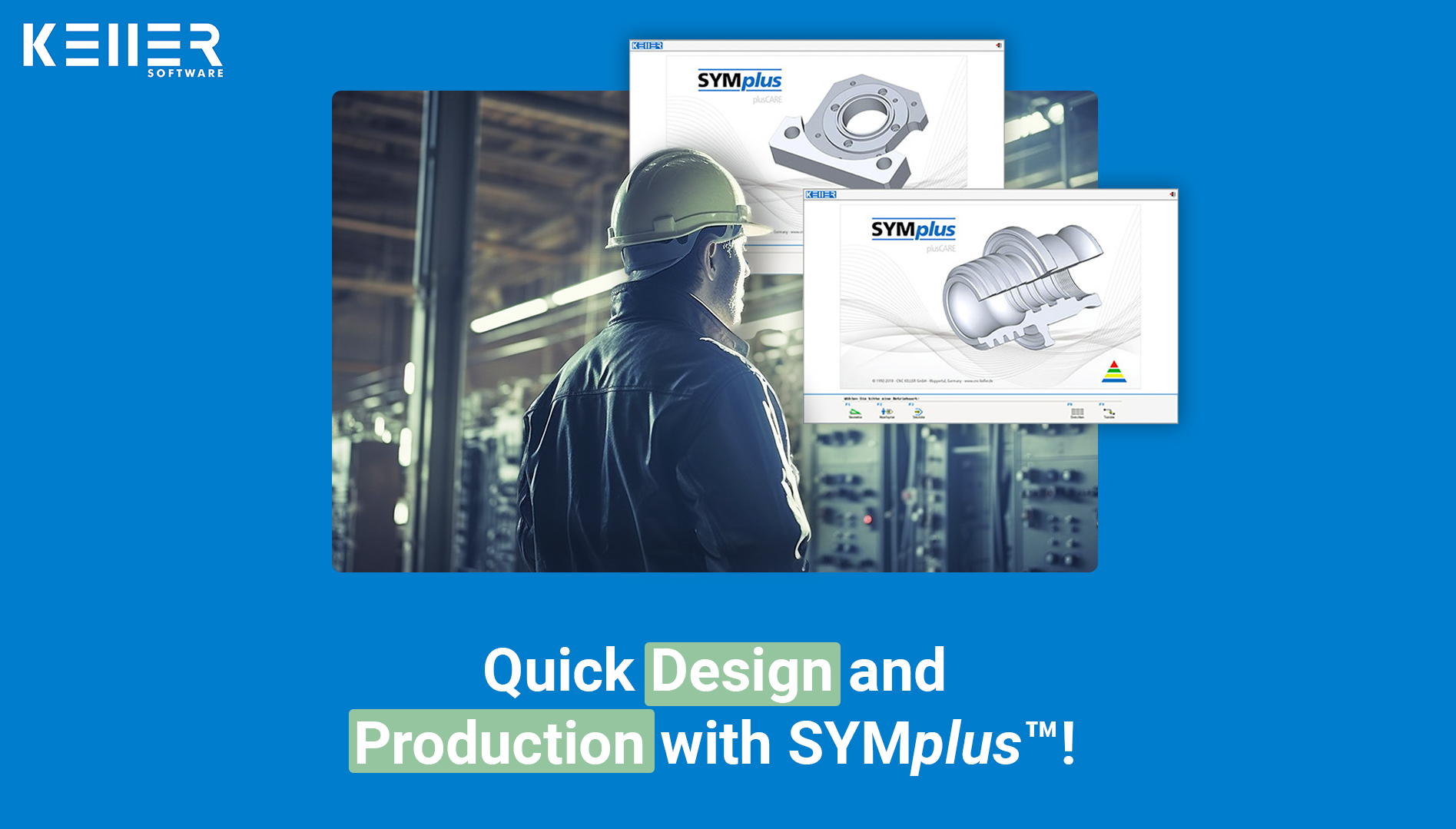

Quick Design and Production with SYMplus™

KELLER.Software offers efficient solutions for your manufacturing process. Boost your Productivity with our CNC-Software SYMplus™.

- Geometry: With the graphical user interface of SYMplus™, you can quickly take workpiece contours from drawings, even if they are not NC-compliant. Alternatively, you can import contours and drilling patterns from CAD drawing data (e.g., DXF). After creating the geometry, you’ll see the finished workpiece in 3D.

- Workplan: SYMplus™’s residual quantity detection ensures short program runtimes. Select the tool and the strategy, and the system automatically detects the remaining quantities. An integrated crash monitoring provides additional safety.

- Postprocessor: Choose the appropriate postprocessor for your CNC machine or controller, and SYMplus™ generates the NC program. Transfer it via USB stick, network, or serial data connection (depending on the controller’s capabilities).

- Tool Data: In the tool database, you can input the optimal speeds, cutting speeds, feeds, and cutting depths for different materials. This gives you the most precise settings for your production at the touch of a button.

Learn more about SYMplus™ for the CNC-Production here: https://cnc-keller.com/symplus-cnc-software/symplus-for-the-cnc-production/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!