Turning according to PAL with SYMplus™ at the BBS Verden (KELLLER.Academy)

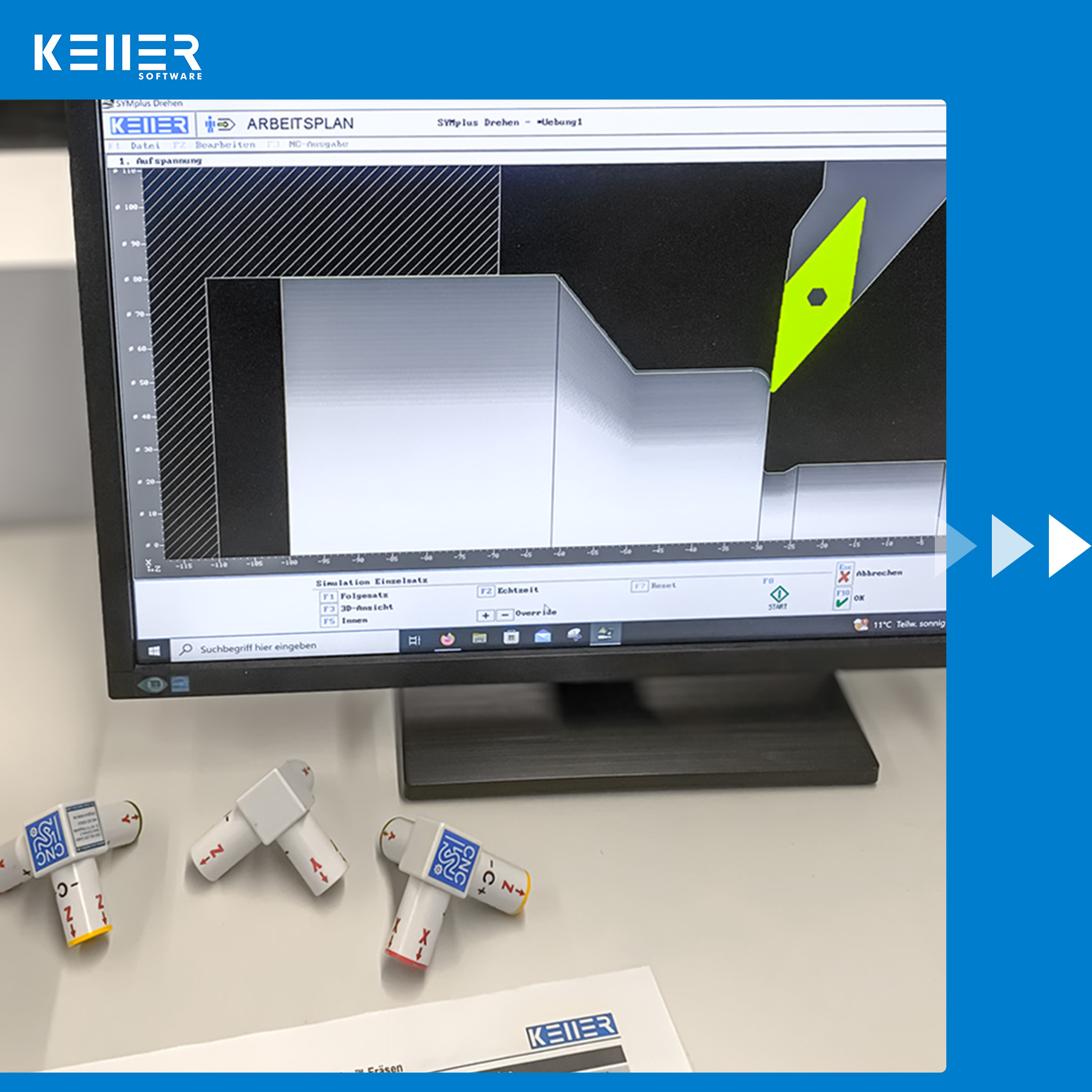

KELLER.Academy on the road! We traveled to the BBS Verden for a SYMplus™ training day. Our KELLER.Academy professor and PAL specialist, Mr. Reckermann, introduced the participants to “Turning according to PAL with SYMplus™” and demonstrated the approach with 2-axis and driven tools in the G17 and G19 planes.

A particular highlight was the successful implementation using a postprocessor for the DMG machine with Sinumerik OPERATE!

The teachers now have plenty of material to practice during the upcoming summer vacation, which starts at the end of the week in Lower Saxony!

Many thanks to everyone for a great time! It was great to be with you in Verden.

- Interested in developing your professional skills too? Browse through the courses offered by the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Basics of graphical programming (CAD/CAM) with SYMplus™ (KELLLER.Academy)

The KELLER.Academy was back in full swing! In this course, “Basics of graphical programming (CAD/CAM) with SYMplus™” was on the agenda.

Many thanks to all participants for a great time! We look forward to welcoming you back to Wuppertal soon.

Congratulations to Mr. Mönninghoff and Mr. Callar from BZI Remscheid, Mr. Schäfer from Becker Dreh- und Frästechnik and two other participants from Aachen on successfully completing their course!

Interested in developing your professional skills too? Browse through the courses offered by the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Basic DIN/PAL programming with SYMplus™ (KELLLER.Academy)

Last week, the KELLER.Academy focused on DIN/PAL programming with SYMplus™.

Congratulations to Mr. Schneider from Wolfgang Loch GmbH & Co. KG, as well as Mr. Harmsen-Pawils from MIELE (Lehrte plant) and Mr. Möllinghoff from BZI Remscheid on their successful completion of the course! Thank you for a great time! We hope to welcome you back to Wuppertal soon.

Interested in developing your professional skills too? Browse through the courses offered by the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy – Training: Basics of DIN/PAL programming with SYMplus™

Another successful KELLER.Academy course is behind us! On a beautiful sunny day, we had the pleasure of welcoming Stadtwerke Wuppertal, MAHLE Ventiltrieb GmbH, LEMKEN GmbH & Co. KG (location Alpen) as well as two teachers from the Friedrich-Dessauer-Schule Limburg.

Topic of the training: Basics of DIN/PAL programming with SYMplus™.

We congratulate all participants on the successful completion of the course!

Would you also like to deepen your knowledge? Discover the courses of the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy – Rolling Bearing Specialist HWG in Renningen

KELLER.Academy paid a visit to Renningen to conduct a customized CAD/CAM training course with a focus on turning for the team at rolling bearing specialist HWG. The goal of this visit was to prepare the employees for the daily use of our CNC software SYMplus in just one and a half days. And the results are impressive!

The training also included optimising the CAD data by integrating the design and testing a program (see photo) on the control.

A big thank you to the HWG team for their trust in our expertise and their hospitality!

Would you also like to deepen your knowledge? Discover the courses of the KELLER.Academy, here: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy – Course: Basics of DIN/PAL programming with SYMplus™

A successful start to 2024 at the KELLER.Academy! This time we had the pleasure of welcoming two employees from Excelitas Technologies in Göttingen to Wuppertal.

Over the course of 1.5 days, they dealt intensively with the basics of DIN/PAL programming with SYMplus™. Congratulations to the participants on passing the course!

Would you also like to deepen your knowledge? Discover the courses of the KELLER.Academy, here: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy – Private course with a CarboTech trainee

An inspiring example of how targeted support can pave the way for a successful professional future!

A trainee from CarboTech Group had missed a few lessons due to illness, so his employer sent him to us at the KELLER.Academy. Thanks to a private course, he can now continue his training with confidence and nothing stands in the way of a successful exam!

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy – Course: Driven tools, level swivel and reform PAL2020

And the time has come again: The last KELLER.Academy course of 2023 is behind us, and the Academy is heading into a well-deserved winter break. But don’t worry, the first course of the new year on “Basics of graphical programming (CAD/CAM) with SYMplus™” will kick off on January 11–12, 2024.

It was truly a fantastic conclusion! For the third time this year, we had the pleasure of welcoming the dedicated teachers from BK Hattingen. We were equally delighted by the visit from representatives of the Oberlin Berufsbildungswerks and Bilstein & Siekermann GmbH & Co.KG.

Congratulations to all the participants for successfully completing the KELLER.Academy course “Driven tools, level swivel and reform PAL2020,” and have a wonderful holiday season. See you next year!

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy – Exam preparation PAL with Hager Group Apprentices

The annual tradition continues: Hager Group trainees were once again our guests at the KELLER.Academy. Over the course of 1.5 days, they prepared intensively for their exams, closed gaps in their knowledge and clarified open questions in order to be as well-prepared as possible.

The entire KELLER.Software team wishes them all the best for their upcoming exams!

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy: Ludwig-Geißler-School in Hanau

The KELLER.Academy visited the Ludwig Geissler School in the Grimm brothers’ home town of Hanau in Hesse.

The participants immersed themselves in our SYMplus™ CNC software, familiarised themselves with the DIN/PAL part using milling examples and took a look at swivelling. The graphic design of a turned part for the NEF 400 machine with SINUMERIK control rounded off the day perfectly. Thanks for inviting us.

Want to learn more about KELLER.Academy courses? Click on this link: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!