New video on YouTube: Crash prevention during 90-degree swivel (CNC Milling, 3+2 Axes)

- Take a look: https://youtu.be/Toqn2b_qMcY

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 4 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Multi-Sided Machining” could look like in reality.

This task includes:

- 90-degree swivel

- Workpiece “cuboid”

- Changed axis positions due to swiveling

- Crash risk

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Swivel around A axis (rotary axis around X) + Thread milling (3+2 Axes)

- Take a look: https://youtu.be/6VBNvs5sRiI

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 3 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Multi-Sided Machining” could look like in reality.

This task includes:

- Swivel around the A axis

- Thread milling G88

- Center hole for M24x2 thread as circular pocket with Ø12 milling cutter

- Plane swivel G15

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Swivel around B-axis (rotary axis around Y) 3+2 Axes

- Take a look: https://youtu.be/DM2BIbqpqRg

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 2 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Multi-Sided Machining” could look like in reality.

This task includes:

- Swivel around the B-axis:

- 1. Zero offset according to PAL G59

- 2. Rotate/pivot coordinate system according to PAL G15

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

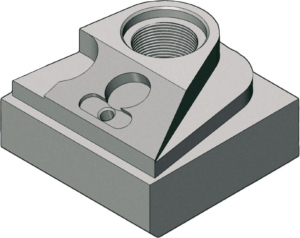

New video on YouTube: Polar dimensioning and PAL G codes (CNC Milling, 3+2 axes)

- Take a look: https://youtu.be/GEDhyNECgcg

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 1 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Multi-Sided Machining” could look like in reality.

This task includes:

- Polar dimensioned Arc in counterclockwise direction G13

- Polar dimensioned arc in clockwise direction G12

- Polar dimensioned individual drilling positions G78

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Detailed CNC machining (PAL G-Code)

- Take a look: https://youtu.be/u5ec5PD7pGw

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 15 from Christiani’s “Collection of tasks in CNC turning technology according to PAL2020” could look like in reality.

This task includes:

- Facing with G1

- External and internal roughing with G81

- External and internal finishing with G42 and G41

- Thread turning with G31

- Grooving with wide and small grooving tool

- Undercutting (undercut DIN509)

- Finishing with 35° V-plate

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Why SYMplus™ is a valuable addition to your lessons (CNC software for training)

- More time for the important things: with SYMplus™, teachers don’t have to spend as much time preparing teaching materials. Instead, they can use this time to focus on imparting subject knowledge and supporting students.

- Qualitative learning content: SYMplus™ ensures that all students have access to high-quality and up-to-date learning content specifically designed for training machinists and similar trades.

- Inhomogeneous learning groups: With SYMplus™, students can learn at their own pace, so inhomogeneous learning groups are not an obstacle and have access to important learning materials, which helps them improve their skills individually.

- Interactive learning environment: Interactive modules allow students to gain hands-on experience without the fear of “breaking something” and directly apply their theoretical knowledge in a safe learning environment.

For more Info: https://cnc-keller.com/symplus-cnc-software/symplus-for-cnc-training/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Complete CNC turning: drilling, roughing, thread cutting

- Take a look: https://youtu.be/8fthYa9h1T4

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 14 from Christiani’s “Collection of tasks in CNC turning technology according to PAL2020” could look like in reality.

This task includes:

- Facing G1

- Drilling according to PAL with cycle G84

- Roughing and internal roughing with cycle G81

- External and internal finishing with G42/G41

- Thread turning according to PAL with cycle G31

- Machining the reverse side after reclamping

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

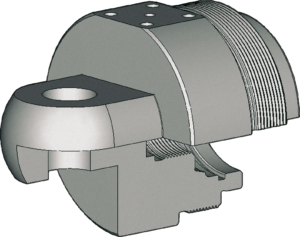

New video on YouTube: Steep Cone Tool Holder with integrated Pull Stud (CNC Turning)

- Take a look: https://youtu.be/ao6tjuqGYbM

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 12 from Christiani’s “Collection of tasks in CNC turning technology according to PAL2020” could look like in reality.

This task includes:

- Radial Grooving Cycle G86

- Circumferential Groove

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video: Final Exam Part 2 for Machinists, Summer 2024 (Turning)

Simulation of the IHK Final Exam (Exam conducted by Chamber of Industry & Commerce, Germany) Part 2 for Machinists, Summer 2024, CNC Turning is now available on YouTube:

- Watch the video: https://youtu.be/rMk0jaUg78w

In the Turning examination task this time, all machining operations had to be carried out with driven tools on chordal surfaces (G19 IP5). In particular, gaps in the cycle calls (G7x) had to be filled, where the candidates needed to understand the axes in the G19 plane (YZ). In contrast to milling, however, it was not necessary to program entire contour trains. Instead, they were required to determine individual coordinates for the “center tolerance” and ISO fits. There were further gaps for recesses, an internal recess and jump addresses in program part repetitions.

- Interested to see more videos like this? Click on this link to visit us: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Newsletter June 2024

The exams are finally over and the summer vacation is just around the corner. But before you go fully into vacation mode, let’s take a look back at the exams – especially at the tasks given. What content was covered? What tricky challenges had to be mastered this year?Bye-bye exam stress, Hello summer!

Milling:

There were no major surprises in the milling exam. Of course, it was necessary to master the functions for switching the radius correction on and off and to apply the commands for soft approach and departure that have been changed since 2020.

In addition, contour points had to be read from the drawing and starting point coordinates had to be subtracted from the centre point coordinates, which were always dimensioned absolutely, to calculate I and J. Two fitting dimensions had to be determined, a rotational speed had to be calculated and some gaps in the cycle for thread milling (G88) and tapping (G84) had to be filled – similar to the previous winter exam.

You can view the Milling test task as a 3D simulation here: https://youtu.be/qdoeAGjywiE

Turning:

In the Turning examination task this time, all machining operations had to be carried out with driven tools on chordal surfaces (G19 IP5). In particular, gaps in the cycle calls (G7x) had to be filled, where the candidates needed to understand the axes in the G19 plane (YZ).

In contrast to milling, however, it was not necessary to program entire contour trains. Instead, they were required to determine individual coordinates for the “center tolerance” and ISO fits. There were further gaps for recesses, an internal recess and jump addresses in program part repetitions.

You can view the Turning test task as a 3D simulation here: https://youtu.be/rMk0jaUg78w

When will the next Software-Update be released?

We know that many schools use the summer vacation to update their IT infrastructure, so we’re working hard behind the scenes to get the latest SYMplus update ready for you to download before the summer vacation! As soon as it is available, you will be informed via this newsletter, our social media channels (Facebook, LinkedIn, Instagram) or on our website.

As soon as the update has been released, you can read about all the new features here: cnc-keller.com/symplus-support/new-features-optimizations/

Wish you a relaxing Summer.

– Your KELLER.Software Team

Next Appointments in the KELLER.Academy:

Basics of graphical programming (CAD/CAM) with SYMplus™

- 25.-26. July 2024

- 05.-06. September 2024

Basic DIN/PAL programming with SYMplus™

- 08.-09. August 2024

- 19.-20. September 2024

Driven tools, level swivel and reform PAL2020

- 11.-12. July 2024

- 22.-23. August 2024

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!