Throwback 2017 – Oktoberfest at KELLER

In keeping with the current season, on this #ThrowbackThursday, let’s take a trip down memory lane to not-so-distant past.

Six years ago, the KELLER.Software team celebrated a cozy Oktoberfest, fully decked out and in high spirits. We’d like to send a warm greeting to all our former colleagues. Most of the faces in the photo are still part of our team today, and we’ve welcomed some new ones along the way.

Here’s to the time we’ve shared and to what lies ahead!

Discover more about our history on our website: https://cnc-keller.de/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Text engraving with the elementary G functions G0, G1, G2, G3

New “INSTANT CNC” Video!

We have once again simulated a challenging task using our SYMplus™ CNC software – this time, we’re tackling Exercise 1 from the Christiani booklet “Collection of tasks on CNC technology milling according to PAL2020”.

The exercise task deals with: The elementary G-functions G0, G1, G2, G3 (text engraving)

Just click the link below to watch the video: https://youtu.be/RS77WIRLiLM

Want to stay updated on all our videos and show us some support? Then make sure to subscribe (it’s free!) to the KELLER YouTube channel:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy – training, Basic DIN/PAL programming with SYMplus™

Congratulations and hats off to our neighbours from Wuppertal, KNIPEX, and the Marbach Werkzeugbau GmbH from Heilbronn! They’ve successfully completed our intensive ‘Basics DIN/PAL Programming with SYMplus™’ course at KELLER.Academy, and we couldn’t be prouder! We hope to see you again at the KELLER.Academy!

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Throwback 1988 – Maho MH 600 E

#ThrowbackThursday! Embarking on a time warp to the 80s manufacturing realm! Here’s a glimpse of a Maho MH 600 E from 1988. Back then, the epitome of cutting-edge technology, today it’s an emblem of durability and precision in the CNC milling realm.

Although it’s no longer in production, it continues to reside in a few workshops. Did you have the pleasure of owning or working with a Maho too? Share your memories in the comments!

Discover more about our history on our website: https://cnc-keller.de/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Round workpiece with a “thick” 2 mm chamfer

New “INSTANT CNC” Video!

We have once again simulated a challenging task using our SYMplus™ CNC software – this time, we’re tackling Exercise 10 from the Christiani booklet “Collection of tasks on CNC technology milling according to PAL2020”.

The exercise task deals with: A round workpiece with a “thick” 2 mm chamfer.

Just click the link below to watch the video: https://www.youtube.com/watch?v=QqFv-UaJaGI

Want to stay updated on all our videos and show us some support? Then make sure to subscribe (it’s free!) to the KELLER YouTube channel:

https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Pre-milling circular pocket, Rectangular pocket and Recesses, Finishing, Drilling

New “INSTANT CNC” Video!

We have once again simulated a challenging task using our SYMplus™ CNC software – this time, we’re tackling Exercise 9 from the Christiani booklet “Collection of tasks on CNC technology milling according to PAL2020”.

The exercise task deals with: Contour milling with cutter radius compensation, pre-milling of a circular pocket, rectangular pocket and recesses, finishing, drilling.

Just click the link below to watch the video: https://www.youtube.com/watch?v=FwIq_SXQF94

Want to stay updated on all our videos and show us some support? Then make sure to subscribe (it’s free!) to the KELLER YouTube channel:

https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Newsletter September 2023

Vacation is over? Here are the latest updates from “KELLER”.

With the end of summer break in most federal states (teachers from Bavaria and Baden-Württemberg might already be checking their email inboxes), we warmly welcome you back from the summer hiatus. Our newsletter is here to bring you up to speed after the vacation period:

We’re excited to announce that the latest version, SYMplus™ 65, is now available. This update brings a variety of improvements and enhanced features, including:

- Simulators according to PAL2020: numerous enhancements and expansions.

- Turning: No more worries in the 2nd quadrant with the right-hand cutting tool. We’ve fixed this issue, making roughing easy now.

- More flexibility for your milling experience: Additional post-processors support tool preselection.

- Customize SYMplus™ to your needs: Explore the new possibilities for creating individual operation step macros with contours.

Learn more about the new features and optimizations:

Click here >

How to update the software:

Click here >

If you missed our webinar “PAL2020: Changes in the Machinist Examination” or want a refresher, we have great news for you. A recording of this webinar is now available on our YouTube channel (complimentary!). Gain insights into past IHK exams, upcoming changes, handling the current PAL coding, and discover how SYMplus™ can prepare your students for ‘fill in the blanks’ tasks. Please note that the Webinar is currently only available in GERMAN. If you would like to have it in English, let us know and we will find a solution.

Here are the links to the webinar:

Our new video series on YouTube delivers knowledge in less than 1 minute – hence the name “INSTANT CNC”. Quickly and concisely, you’ll get the essential information to quench your thirst for knowledge.

Currently, the series comprises a selection of exercises from the “A collection of exercises on CNC technology Milling according to the PAL2020” by CHRISTIANI. Additional videos, including exercises from the turning booklet, will follow soon.

The structure of these short clips is consistent: First, the drawing is displayed, followed by the 3D simulation using SYMplus™. During the simulation, you’ll receive information about each step of the exercise.

To the playlist „INSTANT CNC“ >

Don’t forget to subscribe to our YouTube channel to not miss any new videos. It’s free for you and would greatly support us. Thank you in advance.

Have a nice day and best regards.

– Your KELLER.Software Team

Much more from KELLER.Software …

SYMplus™ workbooks:

Ideal for PAL exam preparation as well as for normal lessons: The SYMplus™ workbooks (Turning and Milling). The workbooks are organised according to topics and levels of difficulty and offer optimal learning material:

- CNC entry

- DIN basics

- Control-specific technical training

- CAD/CAM

It also includes numerous exercises for successful training and further education.

Next Appointments in the KELLER.Academy:

Driven tools, level swivel and reform PAL2020

- 12.-13. October 2023

- 07.-08. December 2023

Basics of graphical programming (CAD/CAM) with SYMplus™

- 26.-27. October 2023

Basic DIN/PAL programming with SYMplus™

- 23.-24. November 2023

Exam preparation PAL

- 90.-10. November 2023

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

The newsletter from KELLER

Do you know about the KELLER Newsletter? Stay in the loop with regular updates (currently every three months) delivered straight to your email inbox – all completely free!

To sign up, please drop us an email to info@cnc-keller.de. Don’t miss out!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

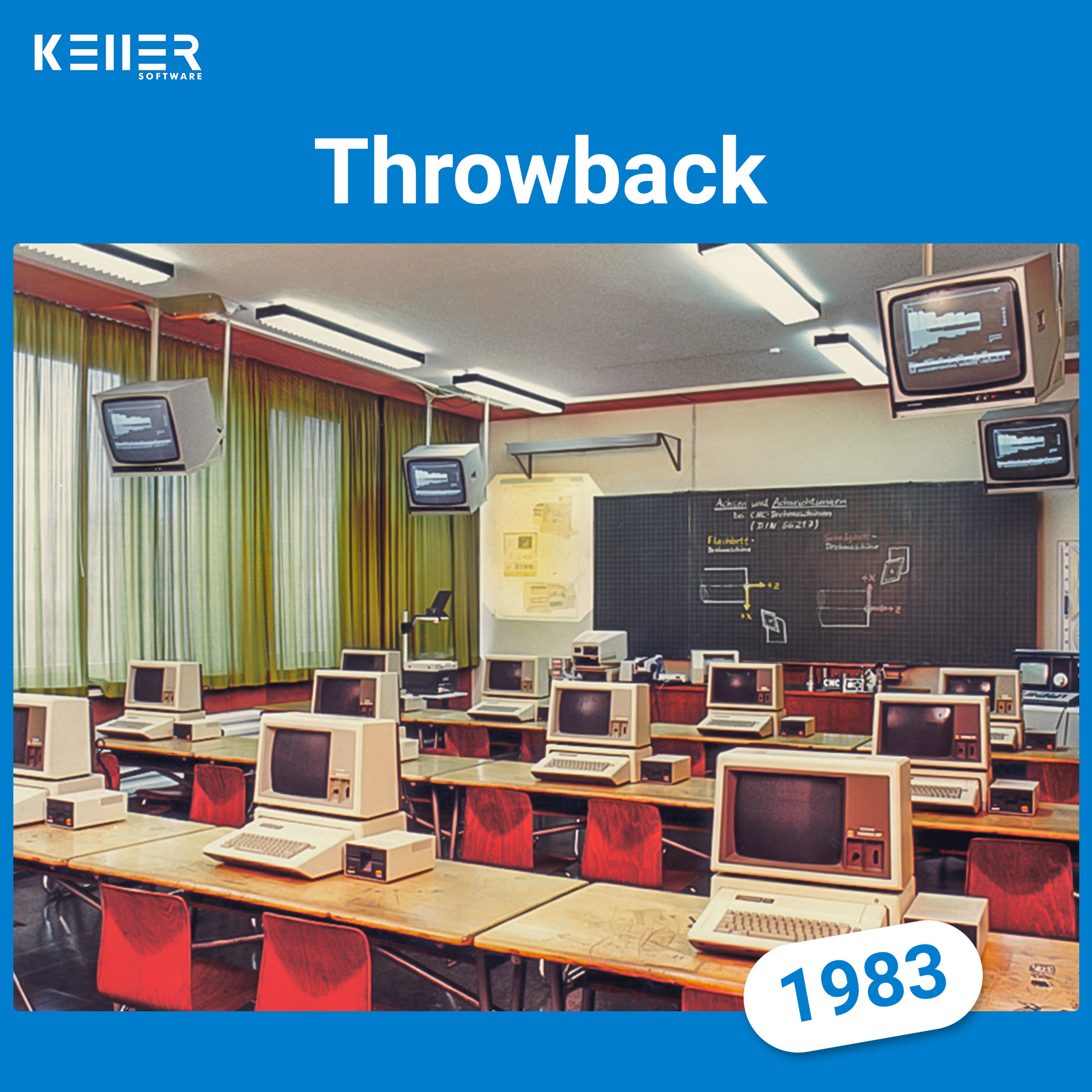

Throwback 1983 – Metal Technology Classroom

#ThrowbackThursday! Traveling back to 1983: this is what a modernized metal technology classroom looked like in 1983.

Discover more about our history on our website: https://cnc-keller.de/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Postprocessor vs. Simulator: What’s the Difference?

Postprocessor vs. Simulator: What’s the Difference? Here is a short and concise explanation! (see photos)

Still not quite clear? You can find the in-depth answer on our support page:

http://cnc-keller.yoursupport.de/cnc.en/entries/000536/difference-between-postprocessor-and-simulator

A postprocessor automatically “translates” a graphically created work plan (CAD/CAM) into an executable program for a specific control.

A simulator replicates the control itself. Some even simulate the original controls 1:1, with identical user interface and operation, such as SinuTrain or the HEIDENHAIN programming station. The simulators from KELLER, on the other hand, use a control-neutral interface, in which most of the commands and cycles of the real control are reproduced.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!