Training at the KELLER.Academy – Basic DIN/PAL programming with SYMplus™

Surrounded by fresh spring greenery, we delved into the basics of DIN/PAL programming with SYMplus™ last week at KELLER.Academy.

Our participants included “HBBK Münster”, “Grünewald Feinmaschinenbau GmbH & Co. KG”, “Bosch Rexroth AG”, and “Lernen fördern e. V.” It was an incredible experience learning and growing together! Would love to do it again anytime!

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

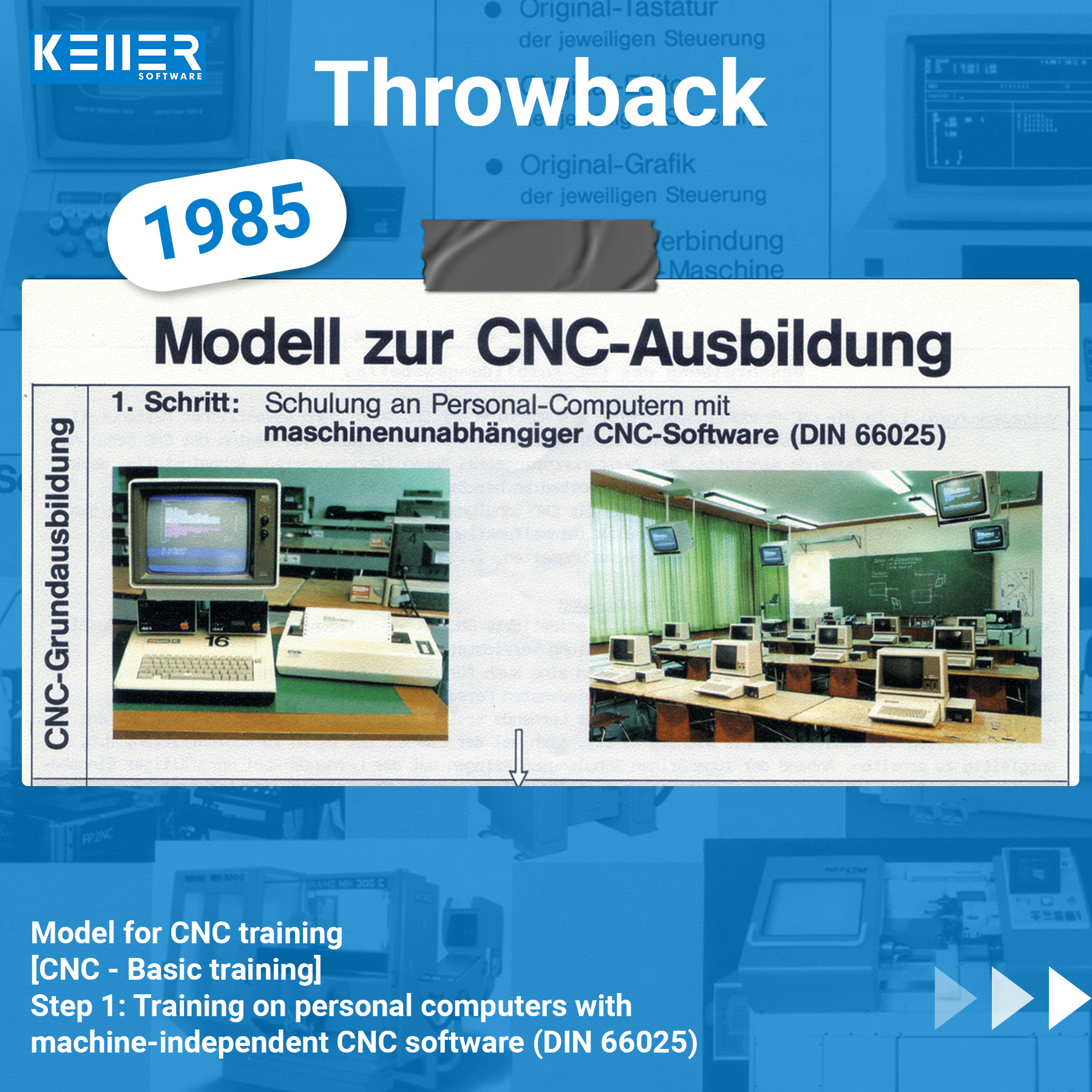

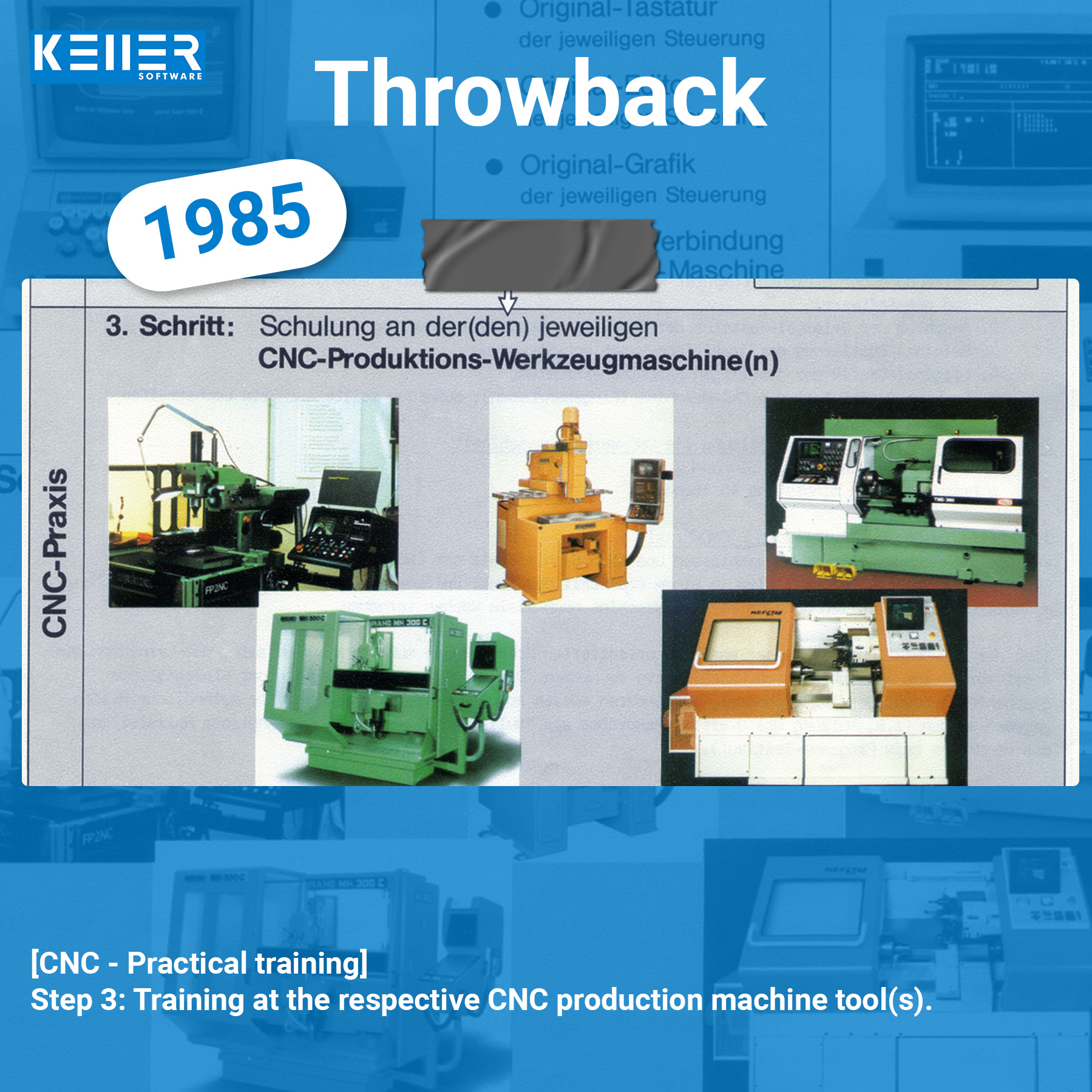

Throwback 1985 – Model for CNC training

It’s #ThrowbackThursday, and this time we’re taking a trip back to the year 1985. We stumbled upon this vintage info sheet that outlines a “Model for CNC training” in just 3 simple steps. It’s fascinating to see how far technology has come since then – those screens and computers have definitely come a long way! But we’re curious, what else do you think has changed in the world of CNC training?

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Good luck for the exams Summer 2023

Exam season is here! The KELLER.Software team wishes all future machinists (and other similar professions) the best of luck in their upcoming exams. You’ve got this!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

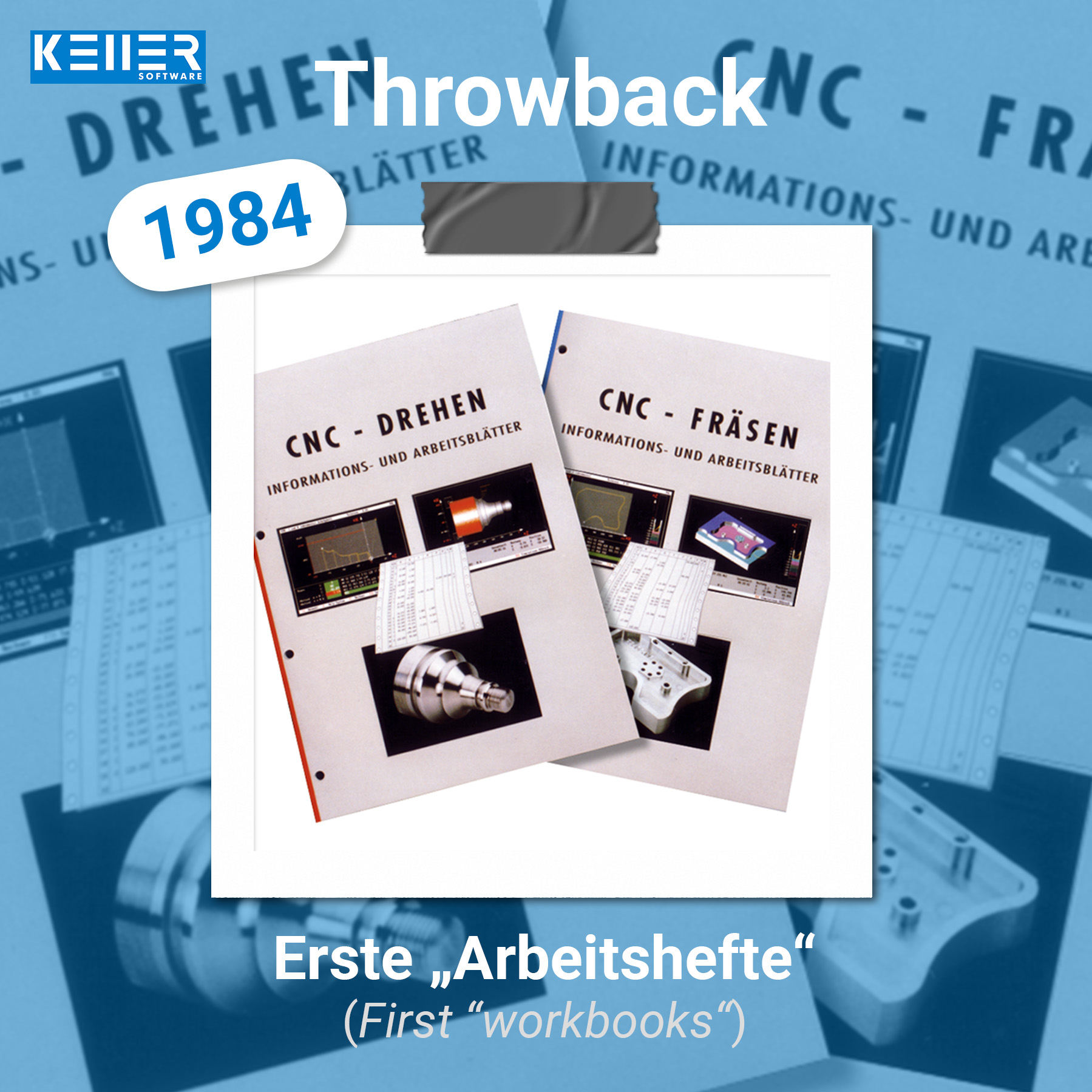

Throwback 1984 – First workbooks, CNC turning, CNC milling

Did you know that our workbooks have been a staple in CNC education since 1984?

With their practical exercises and real-world applications, our workbooks have helped students learn CNC technology for decades. And even today, they remain a popular choice for educators who want to provide engaging and effective learning materials.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

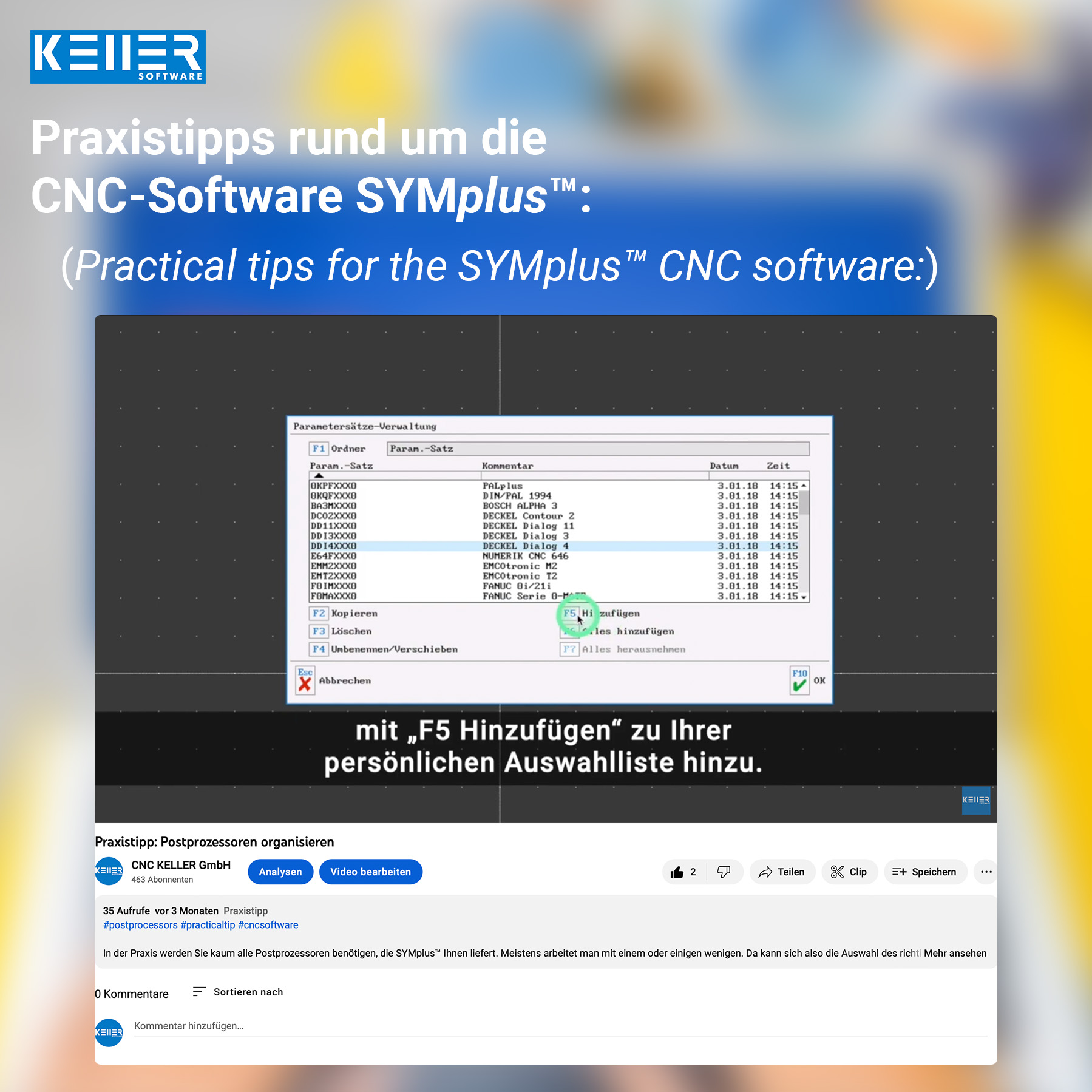

KELLER.Software on YouTube

Check out CNC KELLER GmbH on YouTube! Simply search the name “CNC KELLER GmbH” or enter https://www.youtube.com/@CNCKELLERGmbH in your browser window.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Throwback 1992 – First CNCplus machine

Throwback to 1992: when the first CNCplus machine was built! Even though it’s been long discontinued, we can’t help but admire the amazing work of our team back then. But let’s not forget the real star of the show – the iconic KELLER blue overalls. Who else thinks they’re the coolest workwear around?

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Happy Easter 2023!

Oops, who nibbled on the bunny’s ears? Fortunately, that can’t happen to a metal bunny, thanks to the crash warning in our SYMplus™ CNC software. This protects both bunny’s ears and expensive CNC machines.

Regardless of whether the bunnies are made of chocolate or metal, the KELLER.Software team wishes you a happy Easter holiday! We’ll be back again on Tuesday (11.04.).

And: next week there are still places available in the KELLER.Academy. The topic: “Basics of graphic programming (CAD/CAM) with SYMplus™”.

Click here to register or learn more about the KELLER.Academy courses: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Training at the KELLER.Academy – Driven tools, level swivel and reform PAL2020

Mr. Potjans from OTTO FUCHS Dülken GmbH & Co. KG attended the KELLER.Academy already 2 weeks ago. However, this time the focus was not on the basics of DIN/PAL. Instead, it was about driven tools, the plane swivel as well as the PAL2020 reform. Mr. Potjans of course passed this course as well and the KELLER.Software team congratulates you heartily. We are truly honored that you put so much trust in our KELLER.Academy. Thank you very much.

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

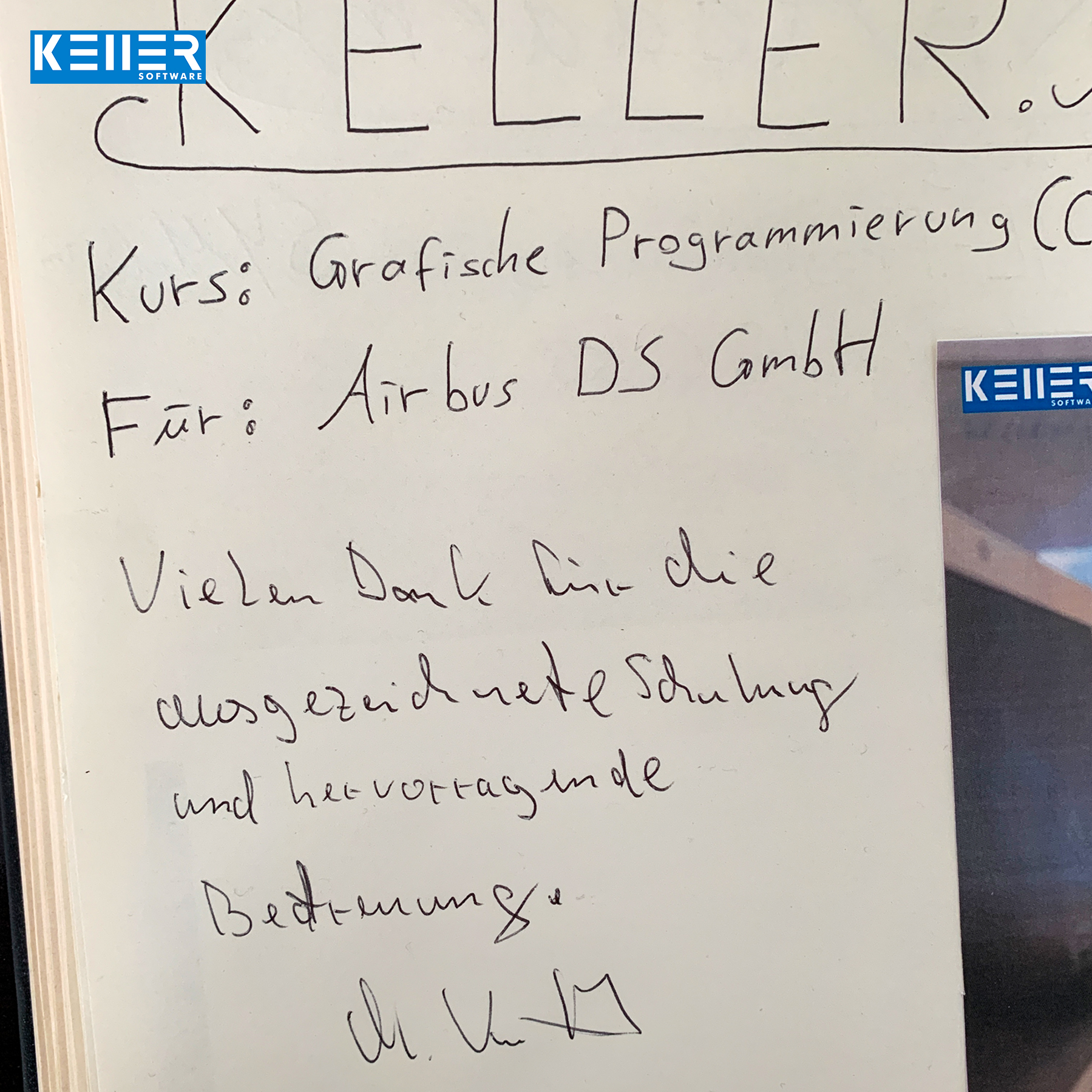

Into the Space with KELLER.Software – Training with Airbus Defense and Space GmbH

“Thank you for the excellent training and outstanding support”

is what the guestbook entry reads after an individual training in our KELLER.Academy.

Mr. Kutsch from Airbus Defense and Space GmbH in Taufkirchen (Bavaria) visited our Academy in Wuppertal for a 2-day CAD/CAM training course (milling).

The company uses CATIA as its design tool, and Mr. Kutsch brought DXF data of practical parts with him for his KELLER.Academy course, which will ultimately be sent into space with satellites, although not by him – his workshop colleague and he “only” mill the models etc.. They work with a DECKEL FP2 with Dialog4 control. By the way, the production of the “real” parts – i.e. those that are sent into space – is carried out exclusively by certified companies.

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Training KELLER.Academy – Course “Basics of DIN/PAL programming with SYMplus™”

Last week was once again: KELLER.Academy. We congratulate Mr. Breden and Mr. Fischer from BK Hattingen, Mr. Bruno from HELMUT FISCHER GmbH and Mr. Potjans from OTTO FUCHS Dülken GmbH & Co. KG on the successful completion of the course. It was a great pleasure for us to welcome you in Wuppertal.

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!