Newsletter December 2023

G54 X 2024.

In this festive season, we would like to wish you a Merry Christmas and thank you for your continued loyalty and trust in KELLER.Software.

There have been challenges, enriching encounters and inspiring cooperation!

There was … a new Software Update

The PAL2020 simulators have been improved and expanded, turning in the 2nd quadrant with a right-hand turning tool is now possible without any problems, and SYMplus™ offers more flexibility thanks to additional post-processors and individual work step macros with contours.

Find out more about the software update >

There was … delicious Instant (CNC) food

Our new “series” on YouTube, “Instant CNC” is your little bite of CNC ready to enjoy in no time at all. The videos are less than a minute-long, making them the perfect snack. Immerse yourself in the world of CNC technology and discover new machining techniques using the 3D simulation from SYMplus™.

There was … a growing Community

On YouTube, we are about to reach the magic mark of 1,000 followers, and we are truly grateful for every single follower! Subscribing to our channel is more than a gesture; it’s vital for our success, as followers are the heart of our community, supporting us and signalling to the YouTube algorithm for wider exposure. And best of all, subscribing to YouTube is completely free! We therefore cordially invite you to become part of our community:

Subscribe to the KELLER YouTube channel now >

There were … over 100,000 video views on TikTok

We have also been active on TikTok since this year. One of our videos went viral there! Thank you for 100,000 views and 3,000 likes – we are grateful!

There was … an exciting webinar on the PAL 2020 commands

The webinar “PAL2020 – Changes to the cutting machine operator exam”, which we held live two to three times a month between February and May 2023, can be now viewed free of charge on our YouTube channel. (Please note: Currently it is only available in German language!)

There was … a price update from 2023

It’s still 2023, which means you can take the opportunity to save money! Our prices will be adjusted from 2024 (does not apply to existing plusCARE™ contracts) so that we can continue to offer you the best possible quality. Orders up to the end of the year will still be processed at the previous conditions.

There are … Insights into the examination task for cutting machine operators

The IHK examinations for cutting machine operators took place on December 6. We used SYMplus to simulate the examination task for CNC milling. You can watch the video on our YouTube channel. (Turning video will come in the following days. Keep yourself subscribed to get updates)

Merry Christmas and a successful start to the New Year

Finally, we would like to wish you and your families a Merry Christmas and a good start to the New Year.

Thank you for another great year in the world of CNC machining. We look forward to mastering the upcoming challenges and successes together with you.

– Your KELLER.Software Team

Next Appointments in the KELLER.Academy:

Driven tools, level swivel and reform PAL2020

- 08.-09. February 2024

- 21.-22. March 2024

Basics of graphical programming (CAD/CAM) with SYMplus™

- 11.-12. January 2024

- 22.-23. February 2024

Basic DIN/PAL programming with SYMplus™

- 25.-26. January 2024

- 07.-08. March 2024

Exam preparation PAL

- 18.-19. April 2024

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy – Course: Driven tools, level swivel and reform PAL2020

And the time has come again: The last KELLER.Academy course of 2023 is behind us, and the Academy is heading into a well-deserved winter break. But don’t worry, the first course of the new year on “Basics of graphical programming (CAD/CAM) with SYMplus™” will kick off on January 11–12, 2024.

It was truly a fantastic conclusion! For the third time this year, we had the pleasure of welcoming the dedicated teachers from BK Hattingen. We were equally delighted by the visit from representatives of the Oberlin Berufsbildungswerks and Bilstein & Siekermann GmbH & Co.KG.

Congratulations to all the participants for successfully completing the KELLER.Academy course “Driven tools, level swivel and reform PAL2020,” and have a wonderful holiday season. See you next year!

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

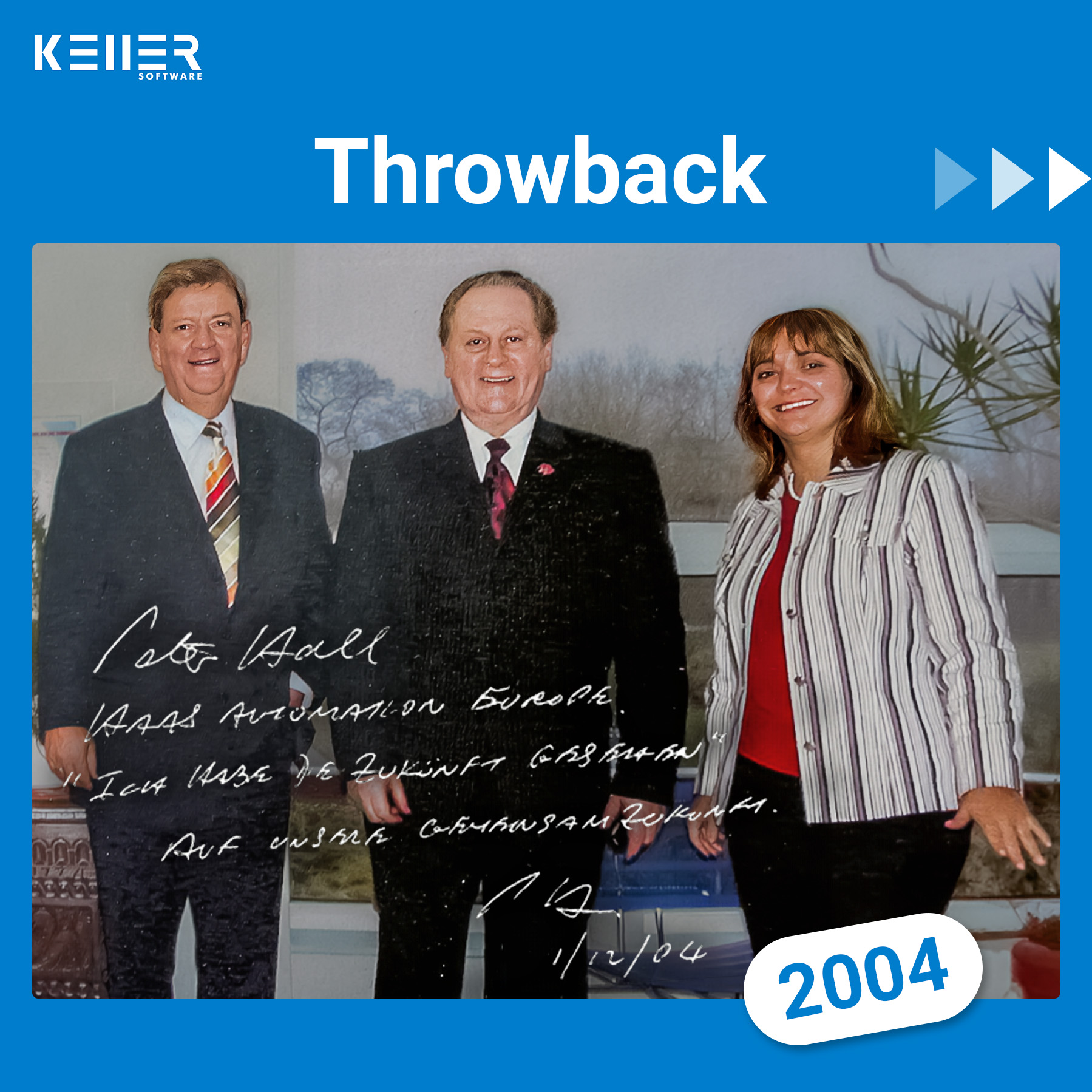

Throwback 2004 – Partnership with Haas

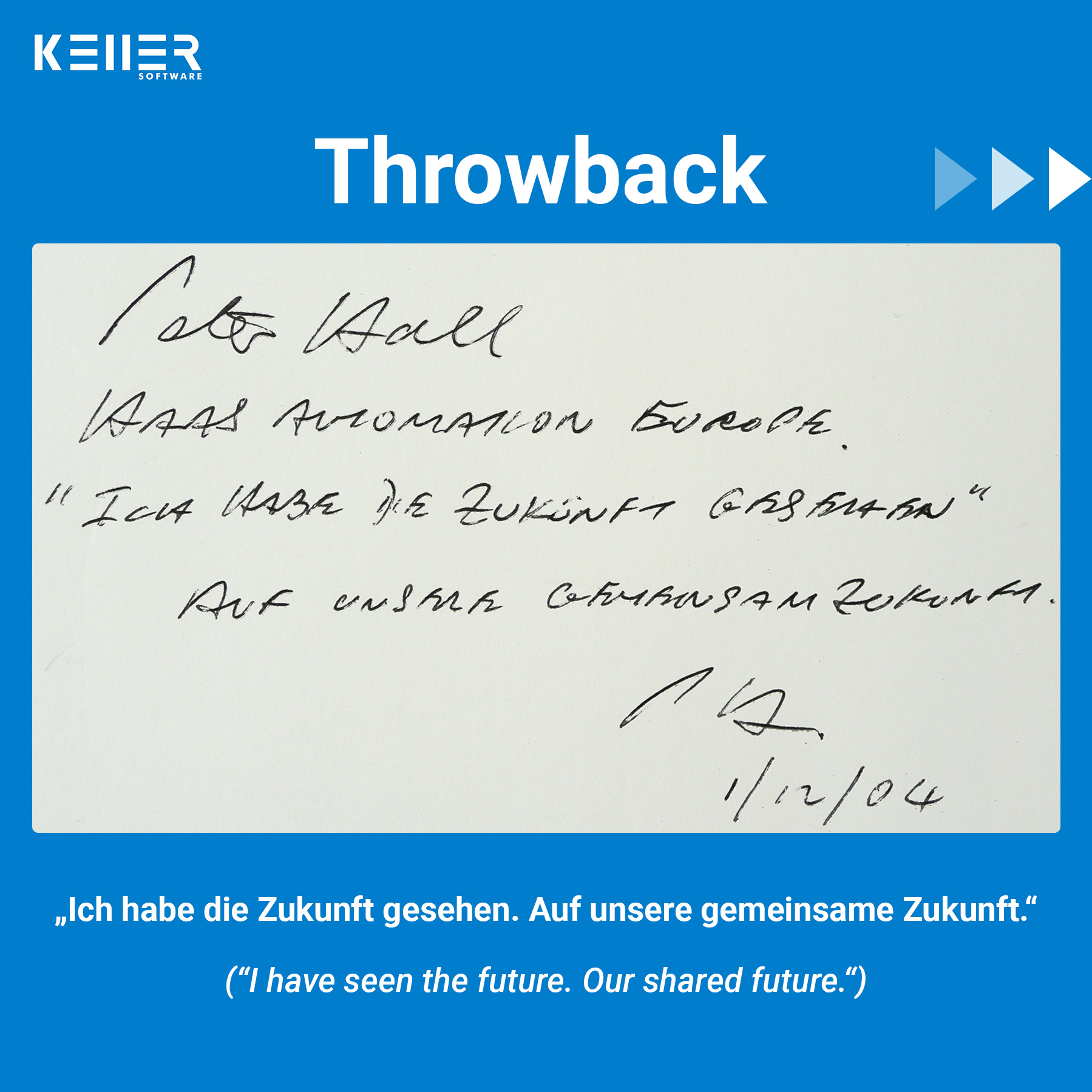

“I have seen the future,” wrote Mr. Peter Hall, Managing Director of Haas, almost 20 years ago, on 01/12/2004, in the KELLER guestbook. A special moment that marked the beginning of a longstanding partnership.

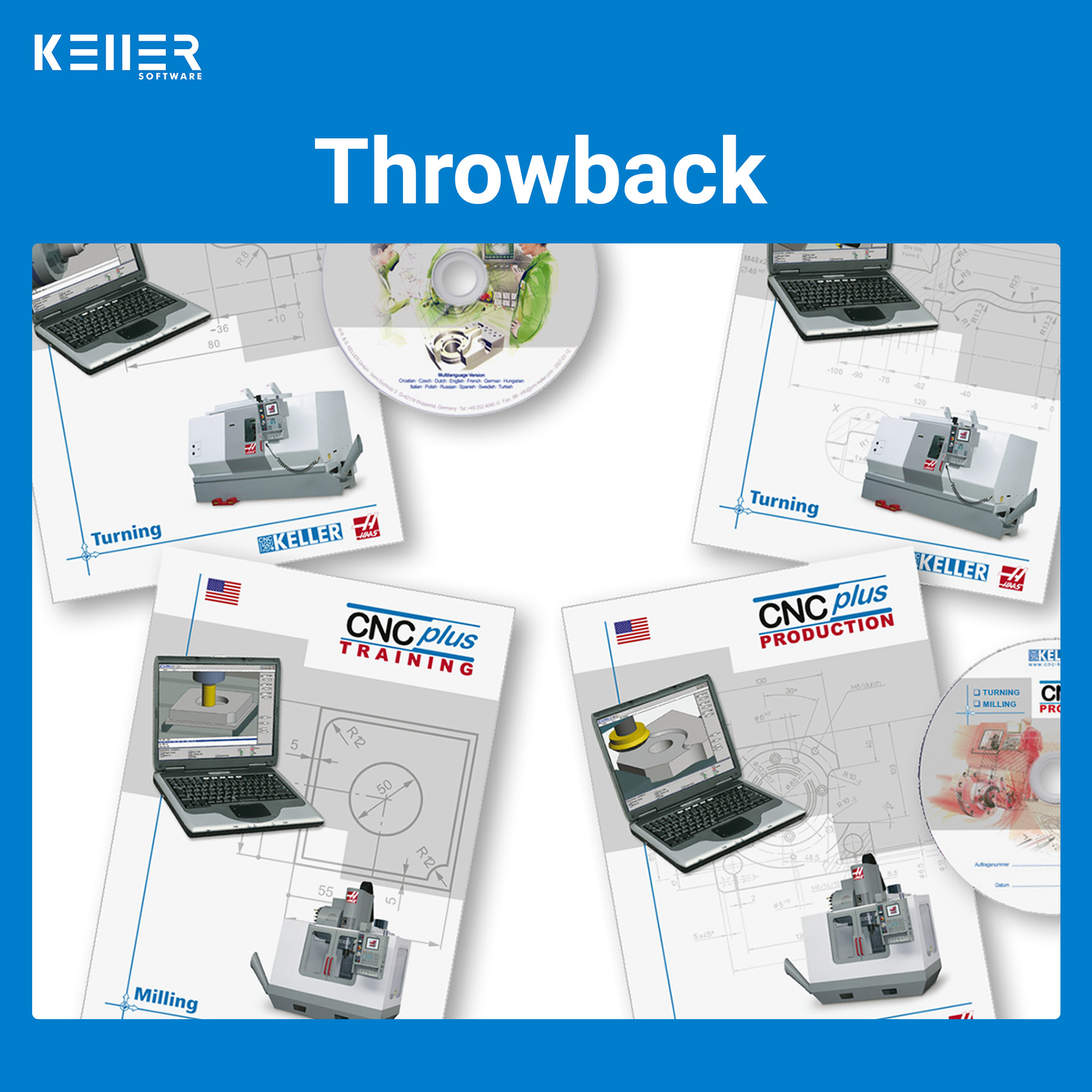

The production lines “CNCplus TRAINING” and “CNCplus PRODUCTION” were established shortly thereafter.

Photo (from left to right): Mr. Keller, Mr. Hall, and Mr. Keller’s daughter.

Discover more about our history on our website: https://cnc-keller.de/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Merry St. Nicholas’ Day!

Merry St. Nicholas’ Day!

In Germany, it is a tradition to place polished boots outside the door on the evening of December 5th. According to legend, St. Nicholas then comes by during the night and fills your boots with sweets and small gifts. 🍬

We may not have sweets for you, but we’ve got a new, interesting video on our YouTube channel!

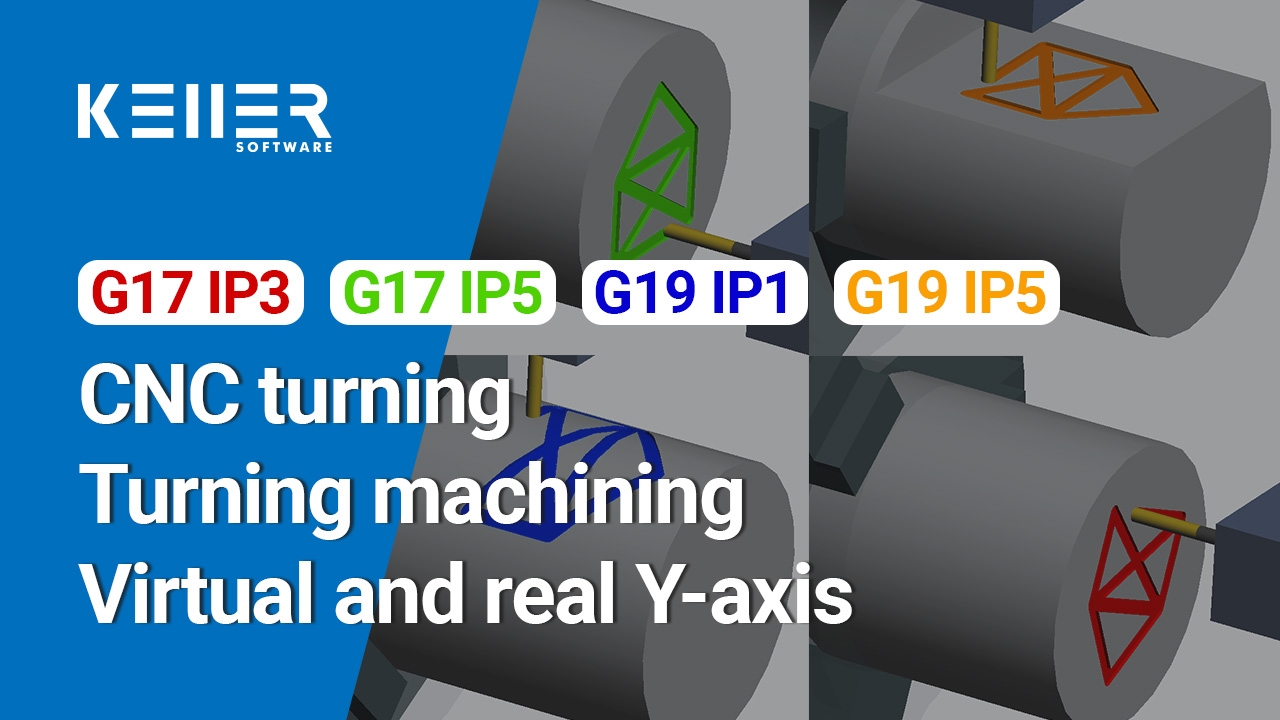

Watch how we simulated the St. Nicholas’ house with our SYMplus™ CNC software in four different ways:

- G17 IP3 – End face machining with virtual Y-axis

- G17 IP5 – End face machining with real Y-axis

- G19 IP1 – Surface machining with virtual Y-axis

- G19 IP5 – Chord surface machining with real Y-axis

Wishing you a magical pre-Christmas season from the KELLER.Software team!

Here’s the link to the video: https://youtu.be/rO6m8pHMJMg

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Last push before the PAL exam – Winter 2023

In two days, the exams begin for the trainee cutting machine operator – three years of training, and now it’s time to show what you’ve got! The entire KELLER.Software team wishes all examinees good luck!

On our YouTube channel, you can watch the practical exam tasks from previous years as 3D manufacturing simulations. This will give you a little insight into what to expect in the practical exam.

Link to the playlist:

Furthermore, on the KELLER support page, you can once again review all PAL commands (turning and milling) at a glance!

- Turning: https://support-en.cnc-keller.de/entries/000244/

- Milling: https://support-en.cnc-keller.de/entries/000245/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Throwback 1986 – R. & S. KELLER GmbH Foundation

Did you know that KELLER didn’t start out as a software company, but as a publishing house?

Under the publisher’s name “R. Keller”, Mrs. Keller first published educational booklets on the topics of CNC machine tools, geometric and technological as well as mathematical basics in 1982. Our SYMplus™ workbooks are still a reminder of this time.

The success of the products finally led to the founding of R. & S. KELLER GmbH by Mr. and Mrs. Keller in 1986. This photo shows the festivities to celebrate the founding of the company.

Discover more about our history on our website: https://cnc-keller.de/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: 3 rectangular pockets on a pitch circle

Check out the latest Video from our “INSTANT CNC” Series!

Immerse yourself in the world of CNC technology and discover machining techniques in our latest “INSTANT CNC” episode.

Using the 3D simulation of our SYMplus™ CNC software, we will show you in this video how task 14 from Christiani’s “Collection of tasks in CNC milling technology according to PAL2020” could look like in reality.

This task includes:

- Pre-milling outer contour, circular pocket and contour pocket

- 3 rectangular pockets on a pitch circle

- Chamfering the rectangular pockets

- Centering and core hole for M10

- Thread tapping

Interested to see it? Click on this link to watch the video: https://youtu.be/3ersyCAiW04

- Interested to see it? Click on this link to watch the video:

- https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Throwback 2016 – User Meeting

#ThrowbackThursday to a special milestone at KELLER.Software! Seven years ago, in 2016, our first “KELLER User Meeting” took place.

These meetings were about more than just dry business discussions; they were primarily about direct exchange with our valued customers, that means with you! Together, we discussed challenges, desired features and progress.

Back then, we also introduced “plusCARE™,” the all-inclusive package for SYMplus™. Today, it’s an indispensable part of our service!

Discover more about our history on our website: https://cnc-keller.de/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New webinar on YouTube: Virtual Shop Floor – How to set up a CNC machine (Part 4)

Part 4 of our webinar series “Virtual Shop Floor” is now online on YouTube! Of course, again with English subtitles, as with the previous videos.

This also means the series is complete. The last part is about how you can use the “Virtual Shop Floor” to learn how to set up a CNC machine (manual start-up, setting the zero point, etc.).

- Click on the following link to watch the 4th and last part of the webinar: https://youtu.be/qmAA9usnkOs

- Or click here if you would like to watch the complete webinar: https://www.youtube.com/watch?v=Asoobm3uOeU&list=PLo0O792GpB40ExOwhuR-QagCyvGGxQkGP

But what exactly is the “Virtual Shop Floor”?

It’s an innovative 3D learning environment brought to you by our CNC software SYMplus™. This immersive experience provides a fun and educational introduction to the world of workshops, machinery, and CNC controls. The initial hands-on exercises in machine setup will prepare you for real-world applications.

Want to stay updated on all our videos and show us some support? Then make sure to subscribe (it’s free!) to the KELLER YouTube channel:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Partnership Hungary and Romania, FL Intercoop

Expanding horizons through international cooperation! A big thank you goes to Dr. Gyurika, with whom we are planning a joint partnership in Hungary and Romania, and to our Hungarian partner, Mr. Ficsor from FL Intercoop, for visiting us here in Wuppertal.

We had the opportunity to talk about CNC training and gain insights that allowed us to look beyond Germany.

In the photo (from left to right): Mr. Mues, Mr. Reckermann, Mr. Ficsor, Dr. Gyurika and Mr. Hanich.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!