3 advantages for a plusCARE™ customer

SYMplus™ with plusCARE™ – The unbeatable combination for your CNC production! But what is „plusCARE™“? Learn more from the photos:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

SYMplus™ Update 65

Dear SYMplus™ users! The wait is over: Software Update 65 is now available!

- Simulators according to PAL2020: Numerous improvements and extensions.

- Turning: No more worries in the 2nd quadrant with the right turning tool. We have fixed the bug, so you can now rough effortlessly.

- More flexibility for your Milling experience: Additional post-processors support tool preselection.

- Adapt SYMplus™ to fit your requirements: Discover new possibilities for creating individual work step macros with contours.

The update is now live! Get the latest version of SYMplus™ and take your CNC production to a new level of efficiency and precision!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

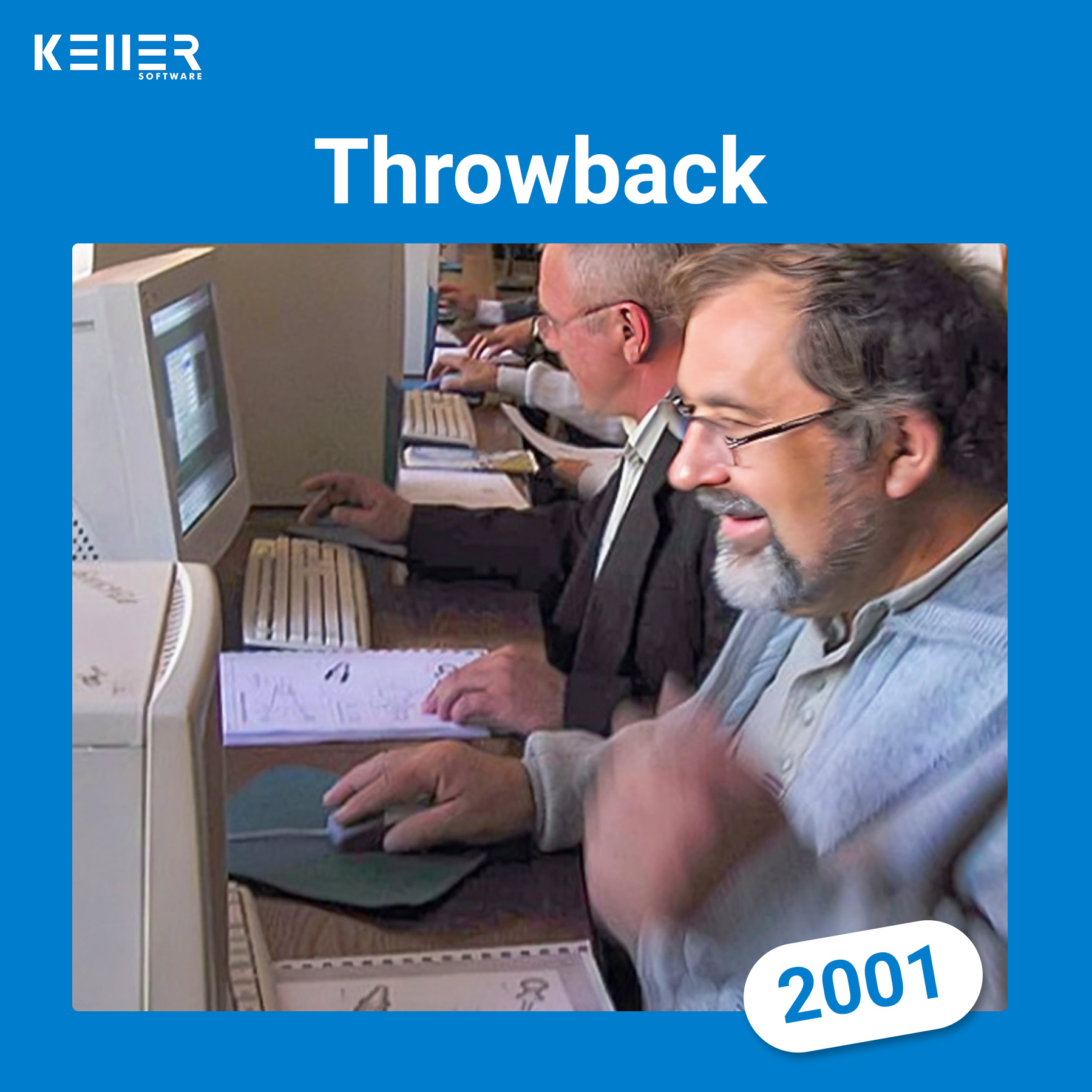

Throwback 2001 – No longer afraid of CNC

Let’s take a trip down memory lane to the year 2001!

Back then, many experienced skilled workers were only familiar with conventional machines, and the emergence of CNC technology raised concerns. But KELLER provided the solution! With their user-friendly software, they could joyfully explore the new manufacturing possibilities.

Even today, KELLER.Software remains committed to nurturing and educating people of all ages. Whether you’re taking your first steps on your educational journey or seeking further development opportunities after years of experience, KELLER is here to support your growth and development.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Various drilling cycles, thread tapping, reaming, countersinking at different levels

New Video on the KELLER YouTube channel!

In this video you will see a simulation of exercise task 4 from Christiani’s booklet “A collection of exercises on CNC technology milling according to the PAL2020” simulated with the SYMplus™ CNC software. The booklet and the video is currently available only in German language. The task involves various drilling cycles, thread milling, reaming, and countersinking on different levels (G81, G82, G84, G85).

Don’t forget to subscribe to our YouTube channel to stay up-to-date with our latest videos and show your support!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy – Driven tools, level swivel and reform PAL2020

Last week, we had two amazing KELLER.Academy training days. This time, the topic was “Driven Tools, Level Swivel, and Reform PAL2020.” We welcomed a trainer from GKN Driveline Deutschland GmbH and two teachers from Theodor-Litt-Schule in Gießen. Congratulations on successfully completing the course! We would be delighted to welcome you back in the future!

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Throwback 1992 – CNCplus control

Did you know that KELLER had developed its own control software called “CNCplus” in the past?

In 1992, being motivated by the success of “Graphic Programming with GKE + CAM”, KELLER implemented this project in cooperation with the company NUM as hardware partner and BOEHRINGER as manufacturer (as well as with some other fabricators).

A total of 120 “CNCplus machines” were created, and the “CNCplus control” was even used for retrofitting projects.

Regrettably, further development with NUM was discontinued after a few years. Still, Mr. Kairies, a NUM employee, who recently celebrated his 33-year anniversary with the company, commented when our CEO, Mr. Mues, congratulated him on LinkedIn: “[…] still have several CNCplus controllers in the field!”

Thus, the success story of KELLER and “CNCplus” remains unforgettable!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

INSTANT CNC – new video on YouTube

Our brand new “INSTANT CNC” Video Series is now online on YouTube. A new video has been added to this series today. Have a look.

In this video, you will see a simulation of the exercise task 3 from Christiani’s booklet “Collection of tasks on CNC technology milling according to PAL2020” simulated with the CNC software SYMplus™.

The exercise task deals with: Pocket cycles, Groove cycles and drilling patterns (G72, G73, G74, G75 as well as G81 with G67 and G77).

Here is the link to the video: https://www.youtube.com/watch?v=TWWaNqezP7c

Additinally, the video from last week, the one that was available only in German then, is now also available in English. Here is the link to that: https://www.youtube.com/watch?v=18oOWc7MCWc

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy visited the David-Roentgen-Schule in Neuwied

Last week, Mr. Reckermann, our KELLER.Academy trainer, visited the David-Roentgen-Schule in Neuwied. He conducted a training session on DIN/PAL (turning and milling) as well as on the topic of driven tools and plane swiveling.

In addition to the dedicated teachers from DRS, an instructor from the firm Wirtgen in Windhagen also participated in this course. On the first day, a teacher and the principal of BBS Heinrich-Haus Neuwied were also part of the group. A big thanks to all the participants for two fantastic training days!

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Throwback 1990 – Band’s music between cnc machines

On October 12, 1990, the KELLER “Technology Centre” was inaugurated. The centerpiece of the show, back then, was the workshop, equipped with 6 CNC machines and 6 different CNC controllers. The evening’s highlight was the band’s incredible music between the machines.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

INSTANT CNC – new video format on YouTube

What’s new, you ask? The answer is “INSTANT CNC” – your little bite of “CNC” ready to enjoy in no time! This is our brand new Video format, mainly meant for our YouTube Channel.

As a German company, naturally our first video is also in German language. Do not worry though, we are working on the English one already and it will soon come your way. The first video in this series is a task from the Christiani booklet “Task collection CNC technology milling according to PAL2020”. With the help of an illustrative simulation from our SYMplus™ CNC software, we explain what this task is about. Further exercises from this booklet will follow.

Here is a link to the video:

https://www.youtube.com/watch?v=F61d7DvBfY4

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!