Mill a Star-Shaped Contour with G2/G3 + Ball End Mill (Video)

In this video, we guide you step by step through Task 8 from the Christiani task collection “CNC Milling Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect in the video:

✅ Program a star-shaped contour with G2/G3

✅ Ball end mill/Radius mill in action: Precise profiling/finishing

✅ Practical application of G-code for various milling techniques

Who is this video for?

Perfect for CNC programmers, machinists, and instructors looking to improve their PAL G-code programming skills for CNC milling.

Subscribe to our channel to not miss out on more tutorials and tips:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Straight or Arc? Milling with G1, G2, G3 (Video)

In this video, we guide you step by step through Task 7 from the Christiani task collection “CNC Milling Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect in the video:

✅ Outer contour with G1, G2, G3 and Cutter Compensation G41

✅ Programming circular and rectangular pockets with G72 and G73

✅ Milling freeform paths precisely with combinations of G1, G2, and G3

Who is this video for?

Perfect for CNC programmers, machinists, and instructors looking to improve their PAL G-code programming skills for CNC milling.

Subscribe to our channel to not miss out on more tutorials and tips:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Internal Thread G85 & G31 + Undercut DIN76, PAL G-Code (Video)

In this video, we guide you step by step through Task 6 from the Christiani task collection “CNC Turning Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect in the video:

✅ Thread programming made easy with G31

✅ Clean undercuts with G85 – DIN 76 compliant

✅ Roughing & finishing cycles – precise and efficient

Who is this video for?

Perfect for CNC programmers, machinists, and instructors looking to improve their G-code programming skills for CNC turning.

Subscribe to our channel to not miss out on more tutorials and tips:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Happy Easter 2025!

Happy Easter from the KELLER.Software team! 🐰

This year, we’ve wrapped up our Easter greetings a little differently: Our apprentice came up with the idea to design an Easter bunny using the geometry module of our CNC software SYMplus™ – completely self-initiated and fully programmed on their own. We were all impressed with the result – and we hope it brings a smile to your face too.

We wish you a joyful Easter, sunny spring days & some relaxing holidays!

- Watch how a simple contour turns step by step into a neat little bunny – fully simulated with our CNC training software SYMplus™.

Subscribe to our channel to not miss out on more videos:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Cutting Threads G85 & G31 + Undercut DIN76, PAL G-Code (Video)

In this video, we guide you step by step through Task 5 from the Christiani task collection “CNC Turning Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect in the video:

✅ Cutting threads with G85 and G31

✅ Undercut according to German DIN76 in CNC turning

✅ Precise application of roughing and finishing cycles for threads

Who is this video for?

Perfect for CNC programmers, machinists, and instructors looking to improve their G-code programming skills for CNC turning.

Subscribe to our channel to not miss out on more tutorials and tips:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

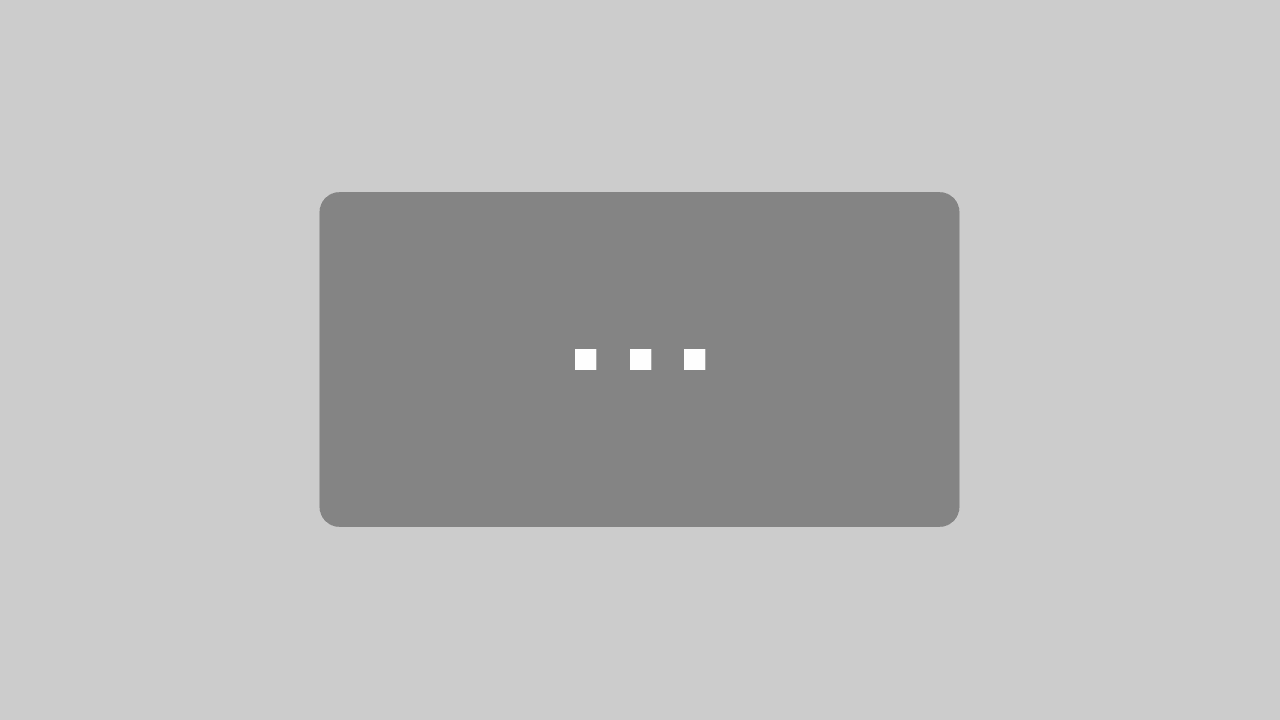

Help Images in SYMplus™ explain CNC Commands and Cycles to you!

Forgot what a specific G-code command does, or unsure how a particular cycle works? No problem! With the SYMplus™ Help Images, you can check anytime and quickly look up all the important details.

- Help images are directly accessible at the command/cycle

- Help images provide a clear visualization, showing you what to do

- Help images are perfect for trainees and anyone who doesn’t program daily

Have you discovered the Help Images in SYMplus™ yet?

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

SYMplus™ Update 67 available: Fixes Windows 11 “24H2” Bug

The latest update for SYMplus™ fixes the compatibility issue with Windows 11 “24H2.” SYMplus™ is now running smoothly again on this Windows version. Additionally, we’ve made further optimizations and bug fixes to enhance performance.

What’s improved?

Find all the details on the new features and optimizations here:

Need help with the installation?

You can find our step-by-step guide here:

Note:

SYMplus™ updates are exclusive to plusCARE™ customers.

Not yet a plusCARE™ customer? Learn more about the benefits of plusCARE™ here:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Even the best tools need care! (SYMplus™ with plusCARE™)

Just like a good tool or a reliable car, your CNC software needs regular maintenance to keep running smoothly in the long term.

With plusCARE™, you get:

✅ Regular updates, ensuring your software is always up-to-date.

✅ Free phone hotline, so you can get support whenever you need it.

✅ Priority support, ensuring quick help when you need it most.

- Rely on a service that ensures your SYMplus™ CNC software remains dependable, so you can focus on what really matters.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Internal Machining: Facing, Drilling & Rough Turning, PAL G-Code (Video)

In this video, we guide you step by step through Task 4 from the Christiani task collection “CNC Turning Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect in the video:

✅ Precise internal machining with G1, G84, and G81 in PAL G-Code

✅ Efficient facing, drilling, and rough turning for internal contours

✅ Practical application of cycles for CNC turning

Who is this video for?

Perfect for CNC programmers, machinists, and instructors looking to improve their G-code programming skills for CNC turning.

Subscribe to our channel to not miss out on more tutorials and tips:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Successful Course Graduation at the KELLER.Academy (DIN/PAL programming)

Last week, Mr. Däschlein from Robert-Limpert-Berufsschule Ansbach (Bavaria) had the unique opportunity to complete the course “Basic DIN/PAL programming with SYMplus™” as a one-on-one training at our KELLER.Academy – and what can we say? Mission completed! Congratulations on finishing the course successfully!

With personalized instruction, he was able to focus on his specific questions, apply what he learned immediately, and expand his knowledge in a targeted way. This is exactly what makes our training stand out: practical, efficient, and perfectly tailored to the needs of our participants!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!