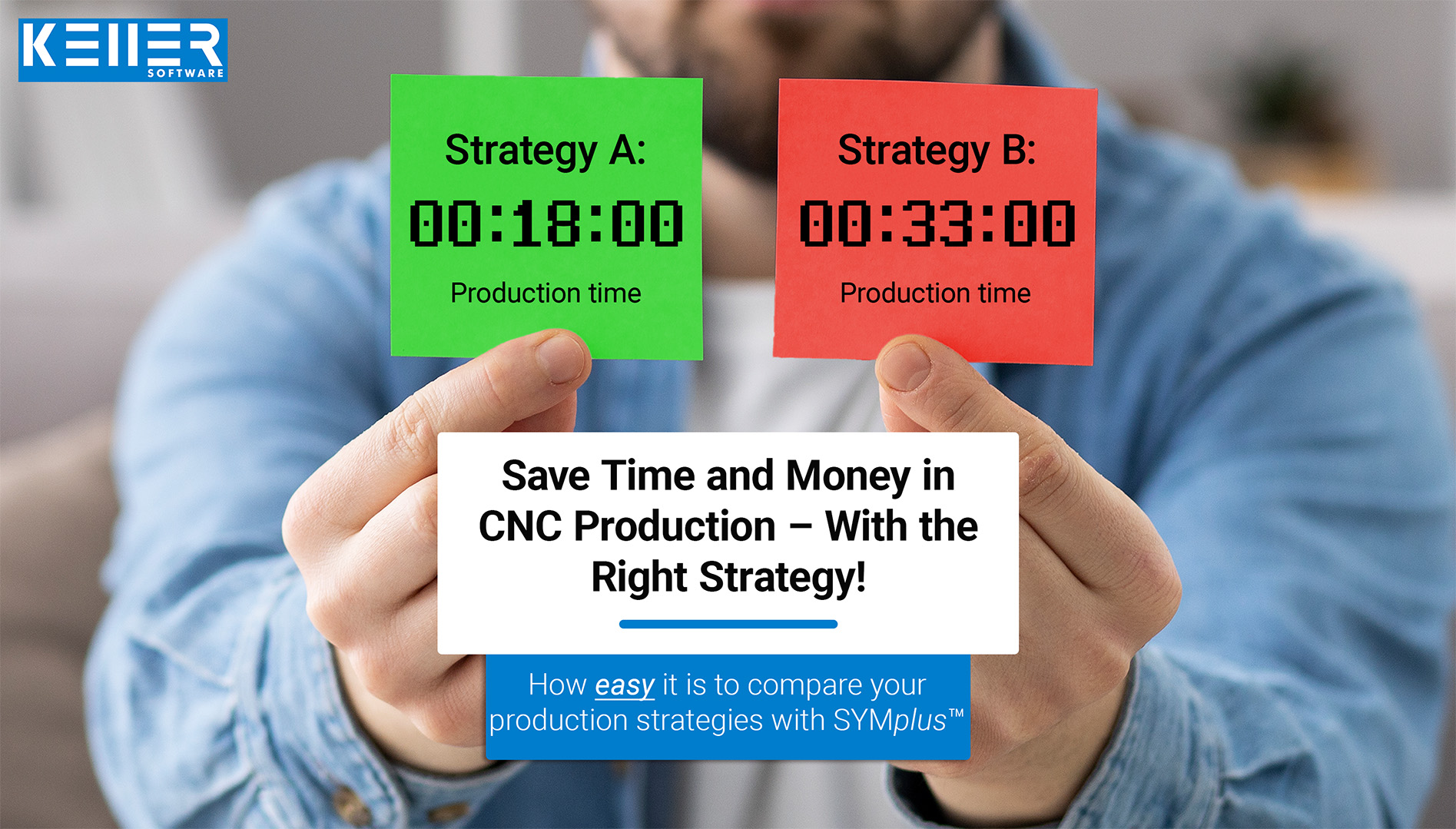

Save Time and Money in CNC Production – With the Right Strategy!

✅ Quick Error Correction: Mistakes can be undone instantly, saving you valuable time.

✅ Efficient Comparison of Manufacturing Strategies: Quickly find the optimal strategy for your production.

✅ Time and Cost Savings: Optimize your processes and save valuable resources.

- Learn more in our YouTube video, where we show how to easily compare manufacturing strategies: https://youtu.be/wSeaABYL7wg

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

CNC Turning of a Tool Holder with Driven Tools

Discover our latest CNC video: Axial grooving, key surfaces and T-slot (with Driven Tools) now on YouTube!

In this video, we guide you step by step through Task 10 from the Christiani task collection “CNC Turning Technology according to PAL2020 with Driven Tools”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect:

- Planning, drilling, roughing, etc.

- A cross drilling with G19 IP0

- Finishing (internal and external)

- Drilling cycle with G86

- 2 grooves on the chord and face surfaces

- Stay up to date!

Subscribe to our YouTube channel so you never miss out on practical tips. Subscribe now – free and with just one click: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Axial grooving, key surfaces and T-slot (with Driven Tools)

Discover our latest CNC video: Axial grooving, key surfaces and T-slot (with Driven Tools) now on YouTube!

In this video, we guide you step by step through Task 9 from the Christiani task collection “CNC Turning Technology according to PAL2020 with Driven Tools”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect:

- Axial turning G88 made easy

- Machining key surfaces: G15 G19 IP5

- How to use the virtual Y-axis effectively

- Tips for two-side machining and T-slot milling

- Stay up to date!

Subscribe to our YouTube channel so you never miss out on practical tips. Subscribe now – free and with just one click: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

What was in the Cutting Machine Operator Exam? (Winter 2024)

What was included in the machining exam? If you took the exam or are preparing for the upcoming one, you can watch the simulations of the machined exam pieces on our YouTube channel!

Note: These videos are available in German only.

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Newsletter December 2024

The skilled workers of tomorrow, the day after tomorrow, and beyond.

2024 – what a year! In the CNC industry, challenges are part of everyday life: every workpiece presents new tasks, and each machine requires an individual approach. Yet, new technologies can sometimes overwhelm us. We understand that. CNC machinists are playing an increasingly central role in Industry 4.0. As machines become more automated and connected, the demands on training and skills for professionals are changing as well. That’s why, once again this year, we’ve worked hard to provide you with not just a “tool,” but solutions that integrate smoothly into your daily work – without unnecessary complexity that costs time, money, and nerves. We believe in thoughtful, small steps that make the biggest difference in the long run. For the professionals of tomorrow, the day after tomorrow, and beyond.

But before we say “goodbye” for this year, we’d like to take a brief look at the winter final exams for CNC machinists. What challenges did candidates face? What was new? On our YouTube channel (@CNC KELLER GmbH), you’ll find a simulation of each exam (Turning and Milling) using our CNC software. It’s perfect for anyone looking to prepare for upcoming exams, or for those who want to analyze the exam workpiece in more detail. You can find the links to the videos under this text (note: The videos are available in German only).

To wrap up this newsletter, we’d just like to say thank you: Thank you for your trust, your collaboration, and for helping us drive the CNC world forward in 2024. Our team will be taking a short break from December 23, 2024, to January 1, 2025, but we’ll be back with renewed energy on January 2.

We wish you restful holidays and a fantastic start to the new year!

Your KELLER.Software Team

Exam CNC Machinist (Part 2, Winter 2024)

Turning:

The turning exam part presented interesting challenges: It involved plan and longitudinal turning, finish machining with program repetition, and working with driven tools.

A highlight was an eccentric circular pocket with an island, programmed using G73 and G79. Other tasks included machining an internal contour, setting allowances, and precisely machining an internal thread.

Milling:

The milling exam piece for CNC machinists in Winter 2024 had a lot to offer: from an external hexagon with polar coordinates to tricky internal contours, circular pockets, and drilling. Programming with G-codes such as G11, G15, and G23 also played a key role.

An important change from previous exams: The separate work plan sheet was replaced by explanatory comments directly in the program, greatly improving orientation.

Have you already installed SYMplus™ Update 66?

SYMplus™ CNC software Update 66 is now available for installation for all plusCARE™ customers. With a wide range of improvements and optimised functions, we want to ensure that you can work with the software as smoothly as never before.

Guide to Update SYMplus™:

›How to install an update‹

Next Appointments in the KELLER.Academy:

Basics of graphical programming (CAD/CAM) with SYMplus™

- 16. – 17. January 2025

- 27. – 28. January 2025

Basic DIN/PAL programming with SYMplus™

- 30. – 31. January 2025

- 13. – 14. March 2025

Driven tools, level swivel and reform PAL2020

- 13. – 14. February 2025

- 27. – 28. March 2025

Exam preparation PAL

- 24. – 25. April 2025

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Milling Grooves on the Face – How to Get It Right with Driven Tools

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 8 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Driven Tools” could look like in reality.

This task includes:

- Milling on the face (driven tools)

- Round groove, cycle G75

- 2 rectangular pockets, concentric to the groove’s starting semicircle

- 2-sided machining

- T-slot cutter

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Face Milling: Drilled Hole Circle (8 Holes) with Driven Tools

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 7 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Driven Tools” could look like in reality.

This task includes:

- Roughing cycle with D-plateDrilled Hole Circle with 8 holes (face milling)

- Virtual Y-axis

- Two-sided machining

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

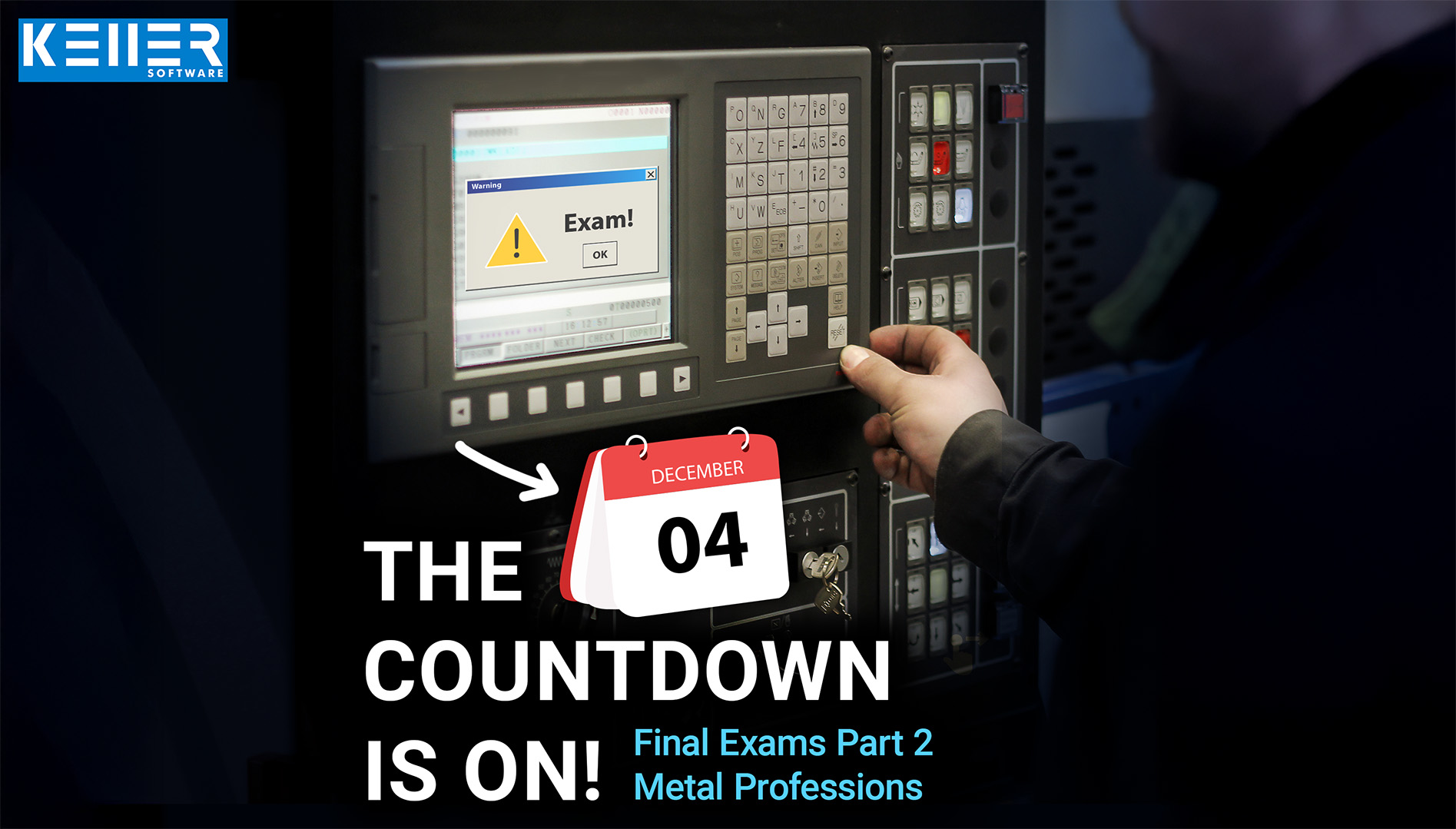

The Countdown is on! (Cutting Machine Operator Exam Winter 2024)

Next Wednesday (December 4th), it’s time – apprentices in the metal professions will put their skills to the test!

Not quite prepared yet? No worries! With the student version of our CNC learning software (Turning/Milling) ‘SYMplus™’, you can make the most of the remaining days!

- Rent affordably (and pay via PayPal, for example)

- Simple and quick

- Flexible license duration (2 weeks – 1 year)

Make the most of the remaining time and enter the exam with confidence!

- Start now and get ready for the exam: *Click here*

The KELLER.Software team wishes you the best of luck!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Turning a Sleeve with Rectangular Cutouts, C+Y Axis

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 6 from Christiani’s “Collection of tasks in CNC Milling technology according to PAL2020 with Driven Tools” could look like in reality.

This task includes:

- Plan turning, drilling, roughing, finishing

- Grooving G86

- Rectangular pocket cycle G72 with program part repetition

- Milling on a chord face (G15 G19 IP3)

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

What the 2024 Open Day at BZI Remscheid was like

Experience technology, discover education!

The Open Day at BZI Remscheid offered exciting insights into the world of (CNC) technology. At our booth, visitors had the opportunity to immerse themselves in our virtual CNC workshop with VR glasses and try out this modern learning method. Throughout the rest of the BZI premises, there were also plenty of opportunities to learn about current training positions and career prospects – two truly successful days!

A big thank you to BZI Remscheid for the fantastic event!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!