Visit from China, Jining University

Last Friday, we had the pleasure of welcoming a delegation from Jining University in the Shandong province of China, led by University President Wang Qingming, here in Wuppertal.

The ‘School of Industry’ with whom we’ve already signed a letter of intent for the purchase of a SYMplus™ licence in China, was represented by Dr. Zhou Ke, the Director of the CNC department. After a delightful exchange of tea and gifts (including a book made of precious silk), they continued their journey to visit our friends at BZI Remscheid.

The KELLER.Software team cherished this valuable opportunity for cultural exchange and looks forward to deepening our collaboration!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

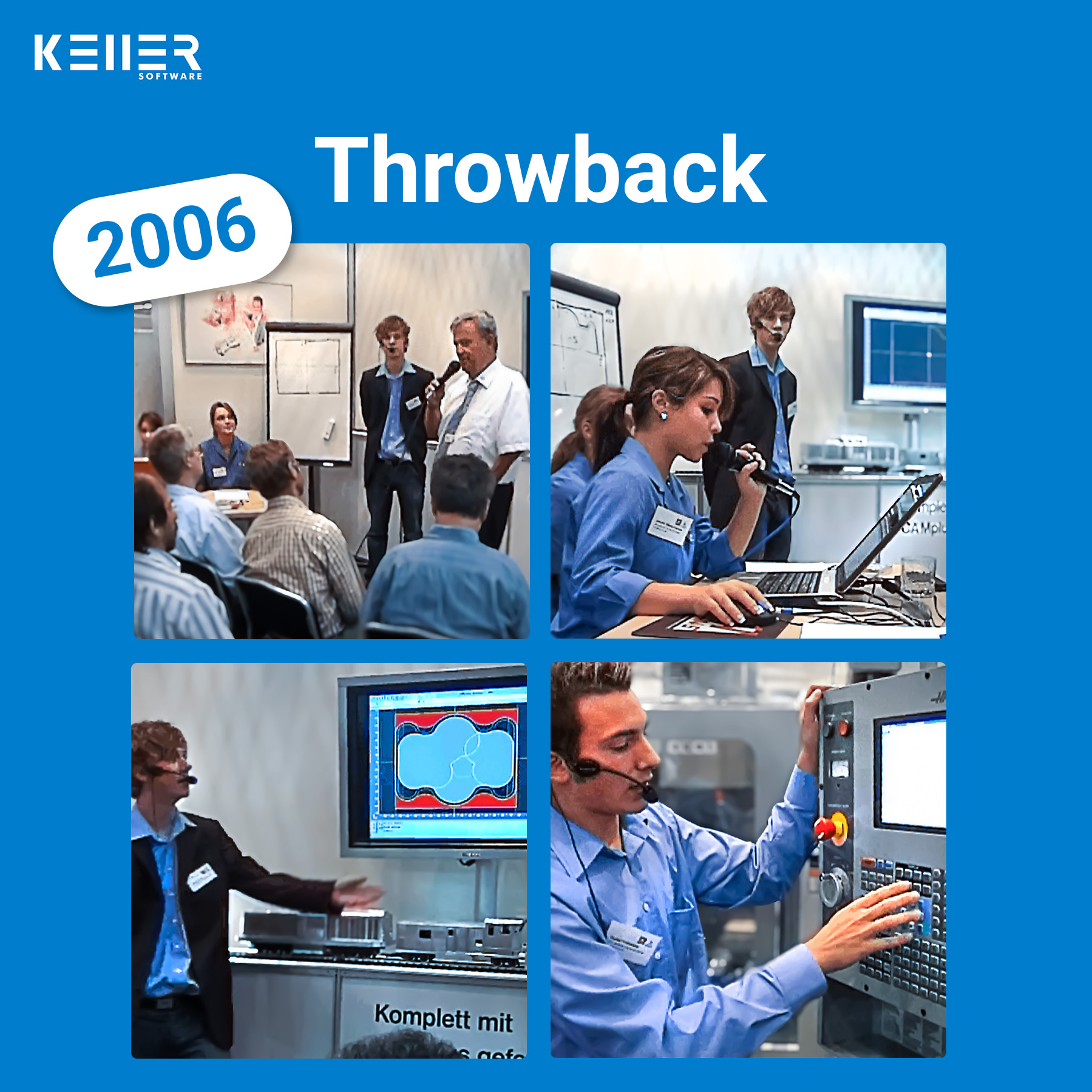

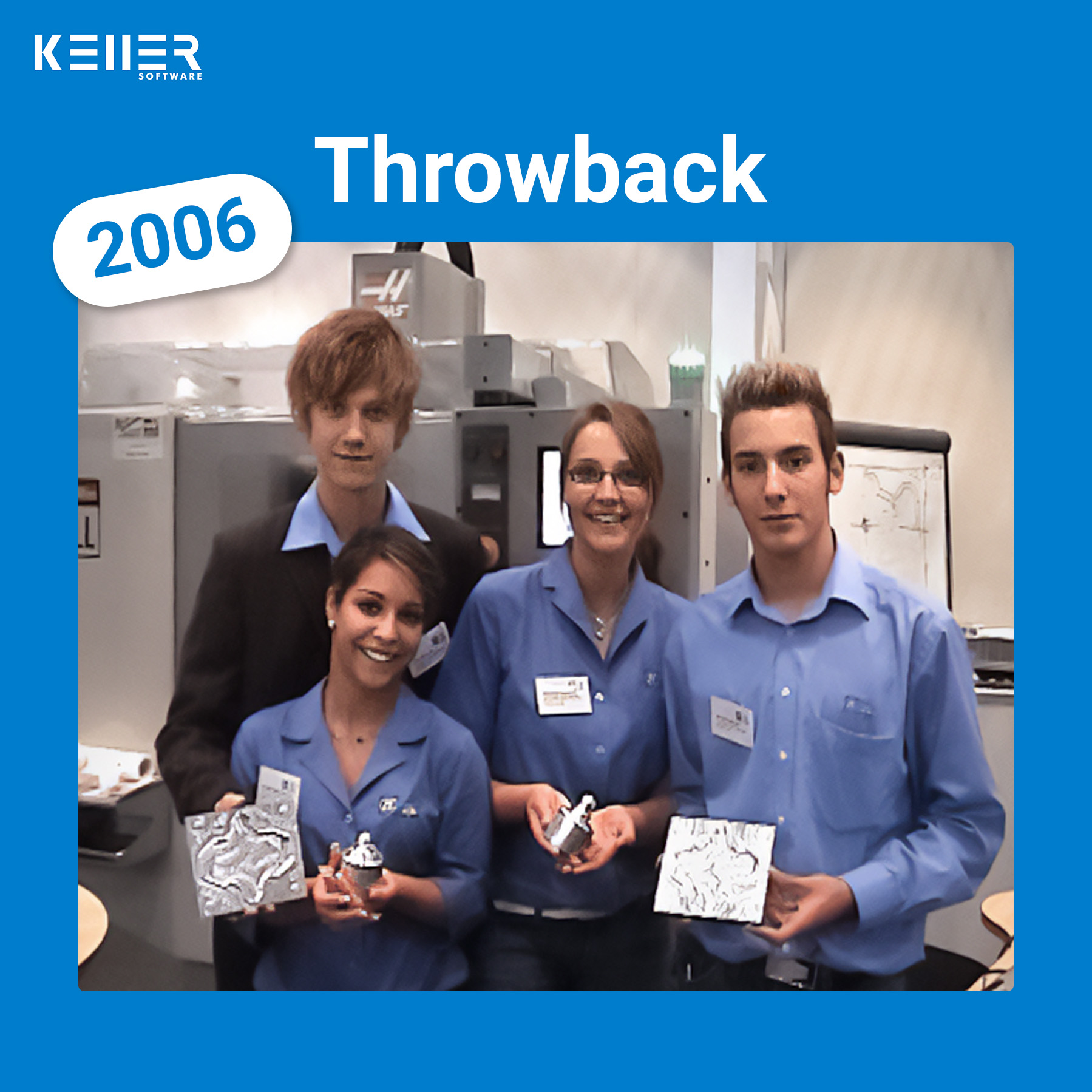

Throwback 2006 – ZF Friedrichshafen apprentices present SYMplus™ at the METAV

A look back into the year 2006: At the METAV trade fair in Düsseldorf, trainees from ZF Friedrichshafen AG were able to demonstrate their skills at the KELLER booth.

Using the graphical editor of our CNC software SYMplus™, they showed the audience how easy it is to develop a milled workpiece from contour to production. To finish things off, they then milled live on a Haas machine.

Almost 20 years later, SYMplus™ continues to delight with its effortless and time-saving user-friendliness!

Discover more about our history on our website: https://cnc-keller.de/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Circular arc grooves and T-Slots

Check out the latest Video from our “INSTANT CNC” Series!

Immerse yourself in the world of CNC technology and discover machining techniques in our latest “INSTANT CNC” episode.

Using the 3D simulation of our SYMplus™ CNC software, we will show you in this video how task 13 from Christiani’s ” Collection of tasks in CNC milling technology according to PAL2020″ could look like in reality.

This task includes:

- Outer contour and full circle in several infeeds

- Rectangular pocket, with a groove in between (also as a pocket)

- Circular arc grooves

- Finishing contours, pockets and grooves

- Roughing and finishing T-Slots

- Drilling and chamfering

Interested to see it? Click on this link to watch the video: https://youtu.be/-Ij7VBVGAl8

- Interested to see it? Click on this link to watch the video:

- https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

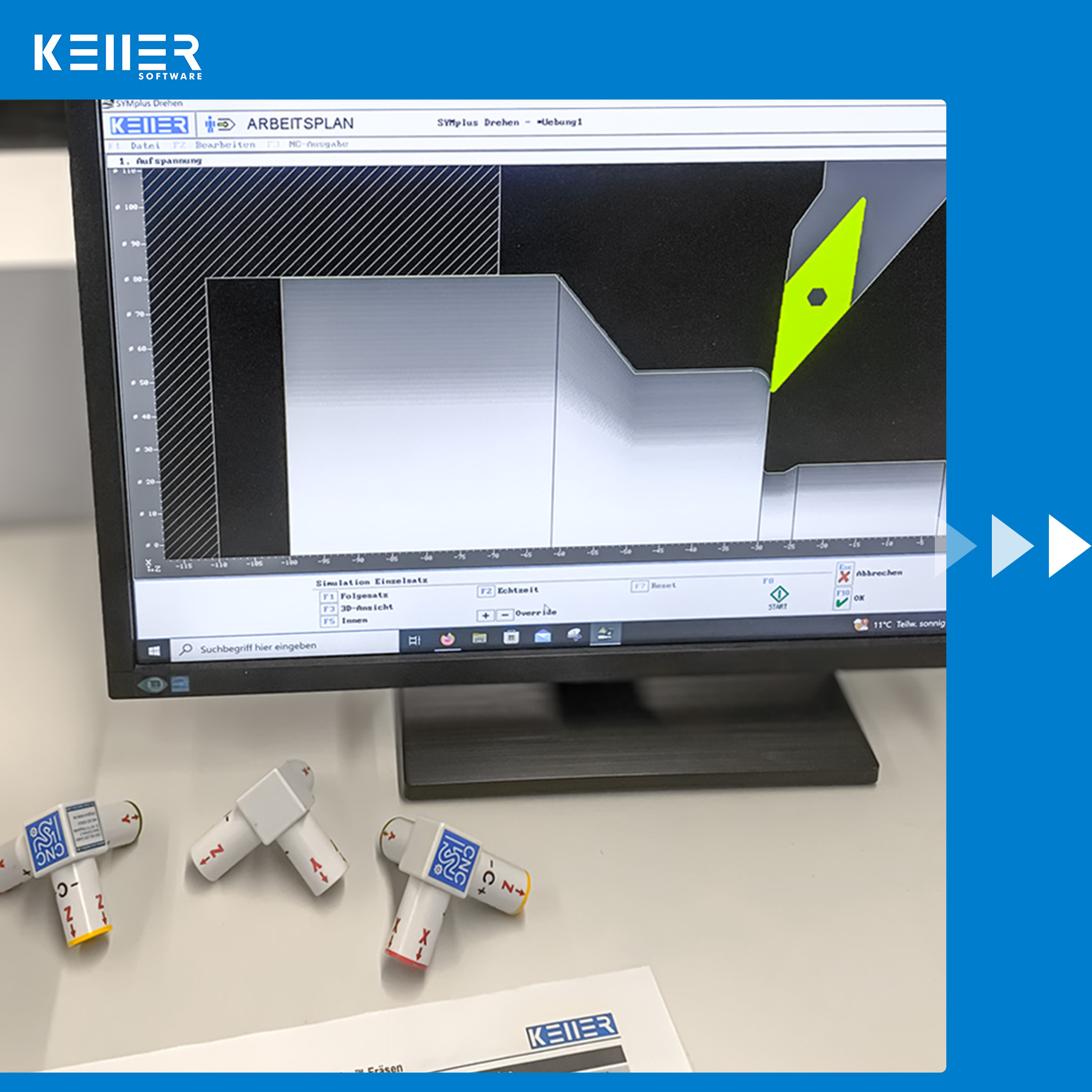

KELLER.Academy – Exam preparation PAL with Hager Group Apprentices

The annual tradition continues: Hager Group trainees were once again our guests at the KELLER.Academy. Over the course of 1.5 days, they prepared intensively for their exams, closed gaps in their knowledge and clarified open questions in order to be as well-prepared as possible.

The entire KELLER.Software team wishes them all the best for their upcoming exams!

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New webinar on YouTube: Virtual Shop Floor – Discover the milling machine (Part 3)

Here is a continuation of our Webinar Series “Virtual Shop Floor” for the CNC software SYMplus™. Part 3 of this Webinar (with English Subtitles) is now available on our YouTube Channel. This part will show you how easy it is with SYMplus™ to discover the structure of a milling machine.

- Click on the link below to watch part 3 of this Webinar Series: https://youtu.be/lWkZkFGMO_A

More segments of this Webinar series are already in the works and will be coming soon.

But what exactly is the “Virtual Shop Floor”?

It’s an innovative 3D learning environment brought to you by our CNC software SYMplus™. This immersive experience provides a fun and educational introduction to the world of workshops, machinery, and CNC controls. The initial hands-on exercises in machine setup will prepare you for real-world applications.

Want to stay updated on all our videos and show us some support? Then make sure to subscribe (it’s free!) to the KELLER YouTube channel:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy: Ludwig-Geißler-School in Hanau

The KELLER.Academy visited the Ludwig Geissler School in the Grimm brothers’ home town of Hanau in Hesse.

The participants immersed themselves in our SYMplus™ CNC software, familiarised themselves with the DIN/PAL part using milling examples and took a look at swivelling. The graphic design of a turned part for the NEF 400 machine with SINUMERIK control rounded off the day perfectly. Thanks for inviting us.

Want to learn more about KELLER.Academy courses? Click on this link: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Throwback 2007 – Horizontal milling machine in Ethiopia (Africa)

In 2007, KELLER.Software visited Ethiopia (East Africa) to demonstrate SYMplus™. There were also guests from Nigeria and Kenya.

The initiative and invitation came from Father Bergamin of the Salesians of Don Bosco in Cairo, where SYMplus™ had already been in use.

The photo shows a conventional horizontal milling machine from Vilh. Pedersen Ldt.

Discover more about our history on our website: https://cnc-keller.de/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

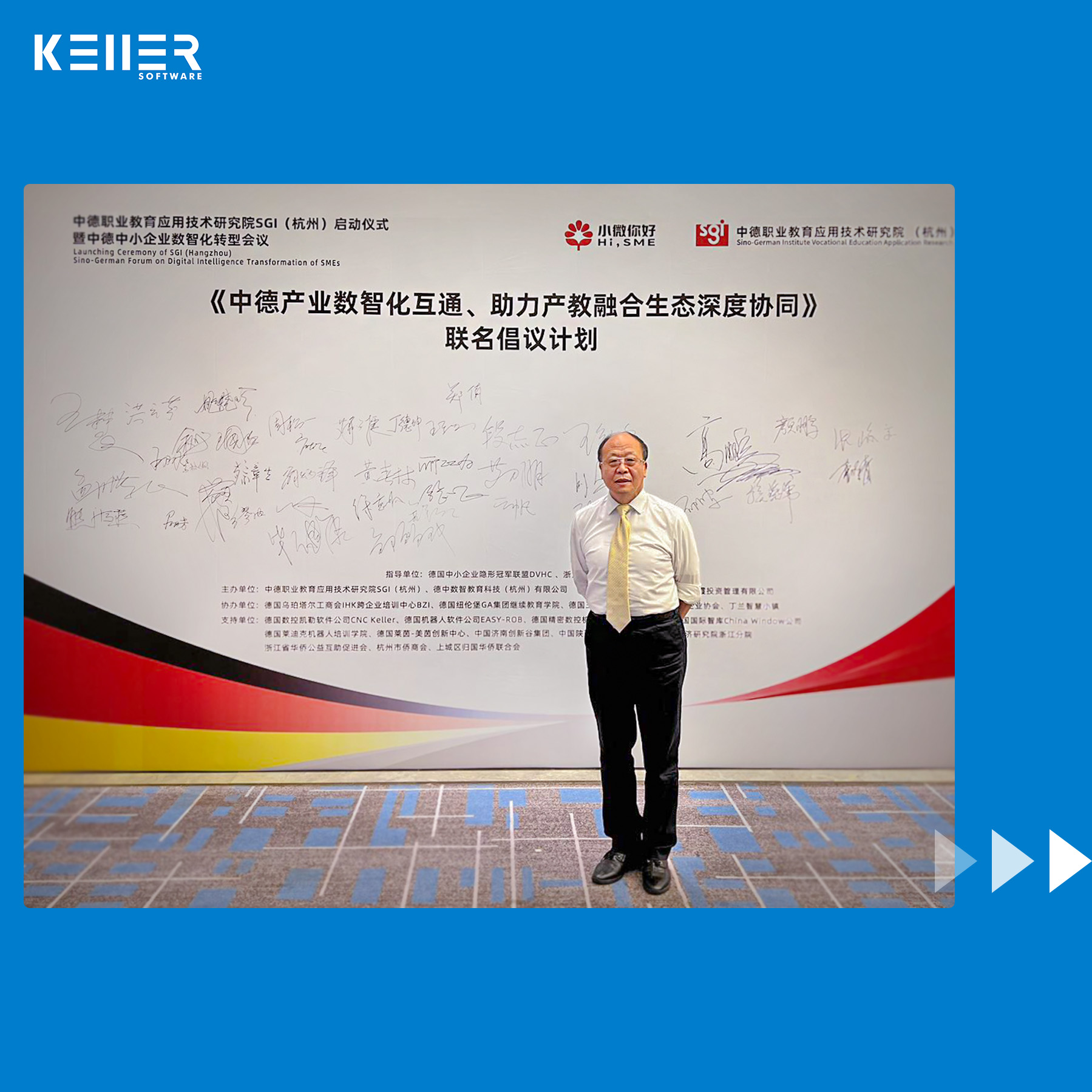

Grand Opening: KELLER CNC training center in China (Hangzhou)

We marked the grand opening of the new CNC Training Center by KELLER.Software in Hangzhou, China, with a magnificent ceremony.

Our long-standing and highly esteemed partner, Mr. Dr. Peng Gao (the man in the photo with the poster in the background or in the other photo, the man on the far right), was our ambassador from KELLER on this special occasion.

A heartfelt thank you to Dr. Gao! Your unwavering support and expertise have played a significant role in making this success possible. Cheers to a lasting partnership!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

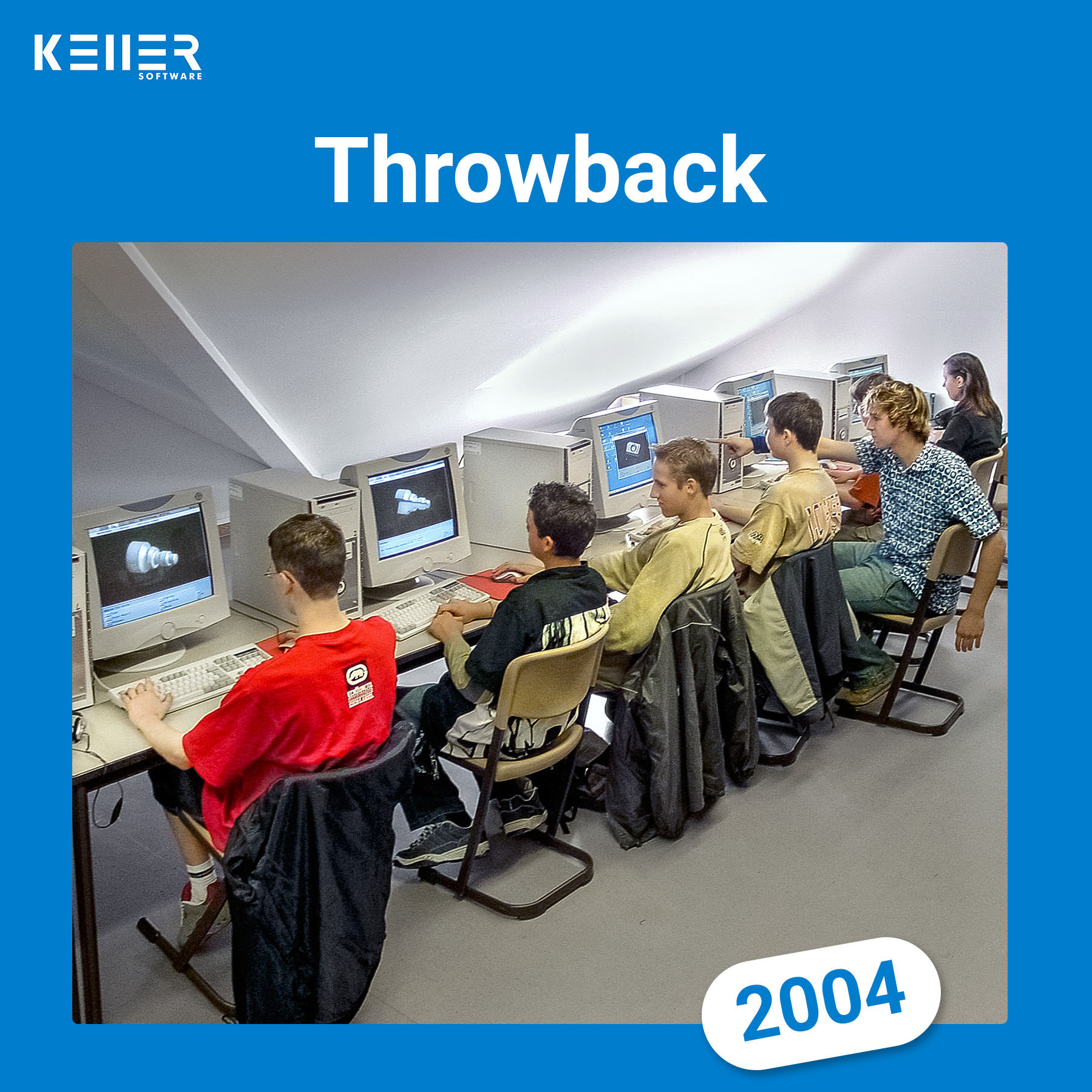

Throwback 2004 – Students learn enthusiastically with SYMplus™

#ThrowbackThursday! Today, we take a trip back to 2004.

In this photo, you can see students exploring the CNC world with SYMplus™.

A lot has changed since then: from bulky tube monitors to sleek screens, from clunky keyboards to elegant designs, from hefty desktop towers to slim laptops that fit in your backpack.

SYMplus™ has evolved as well, but our values remain the same: With ease, experience the CNC world.

Discover more about our history on our website: https://cnc-keller.de/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy – training, Basics of graphical programming (CAD/CAM) with SYMplus™

What an incredible training session it was! Last week, CNC trainers and teachers came together at KELLER.Academy to learn the basics of Graphic Programming (CAD/CAM) with SYMplus™.

A big shoutout to Bosch Rexroth, Würz & Gysler Maschinenbau GmbH, and Berufskolleg Hattingen for visiting us!

The KELLER.Software team warmly congratulates all the participants on successfully completing the course and eagerly looks forward to our next meeting! See you soon!

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!