PRACTICAL TIP – 3 steps to rotary-symmetric contour

July 2021

A pocket or an island contour is usually constructed from the starting point of the contour once around to the end point. In the case of a rotary-symmetrical contour, this would usually be unnecessarily time-consuming and, in part, hardly feasible anyway due to the dimensions.

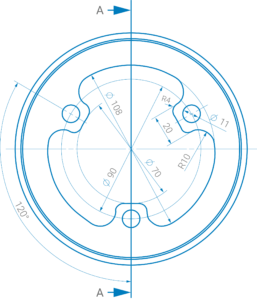

When programming in SYMplus™, you can achieve the complete contour in just three steps. We will demonstrate it using this drawing:

Step 1:

It is sufficient here to actually construct 1/6 of the contour. We start here on one axis (here it is the negative Y-axis). Since we want to construct 1/6 of 360°, the last element, the circular arc Ø108 must have a run-out angle (to the positive X axis) of 60°.

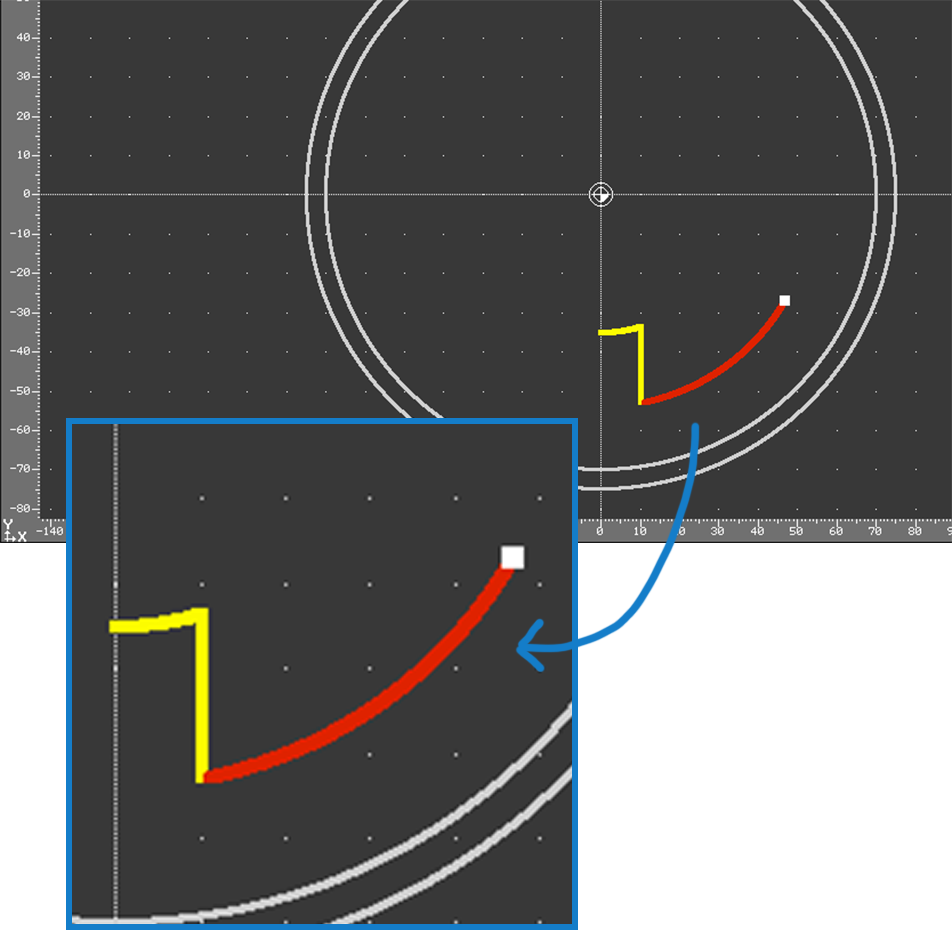

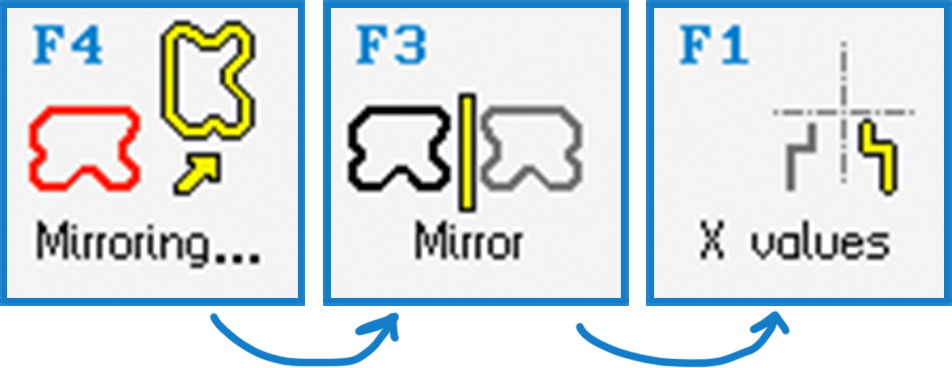

Step 2:

Now we leave the stretch/arc editor and mirror this piece to the Y axis (or the “X values”). It is important that you select “Mirror and connect”, because otherwise we would have single, “loose” contours.

If you make a mistake when flipping, flip in the wrong direction or forget to connect: With Ctrl+Z you can undo this operation and do it right again.

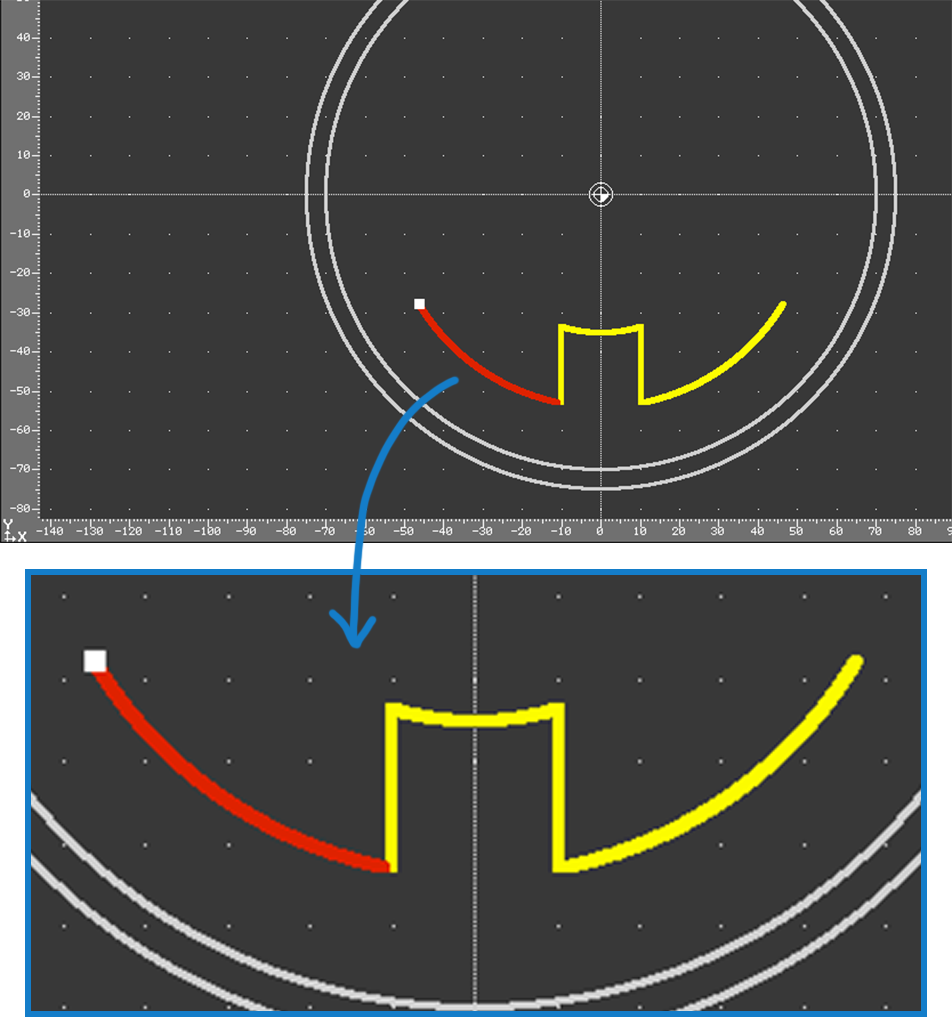

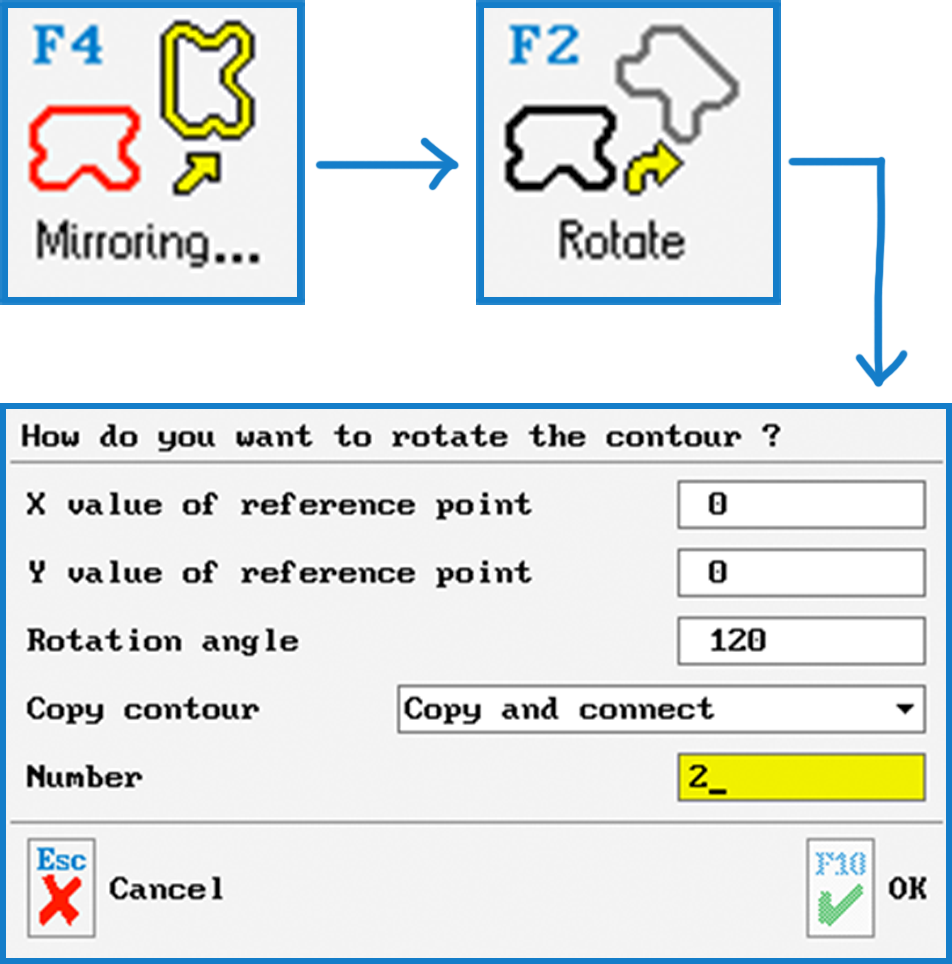

Step 3:

With this we now have 1/3 of the entire contour and can copy and rotate this section 2x by 120°. Again we select “Copy and Join” and as “Number” the number of copies, namely 2.

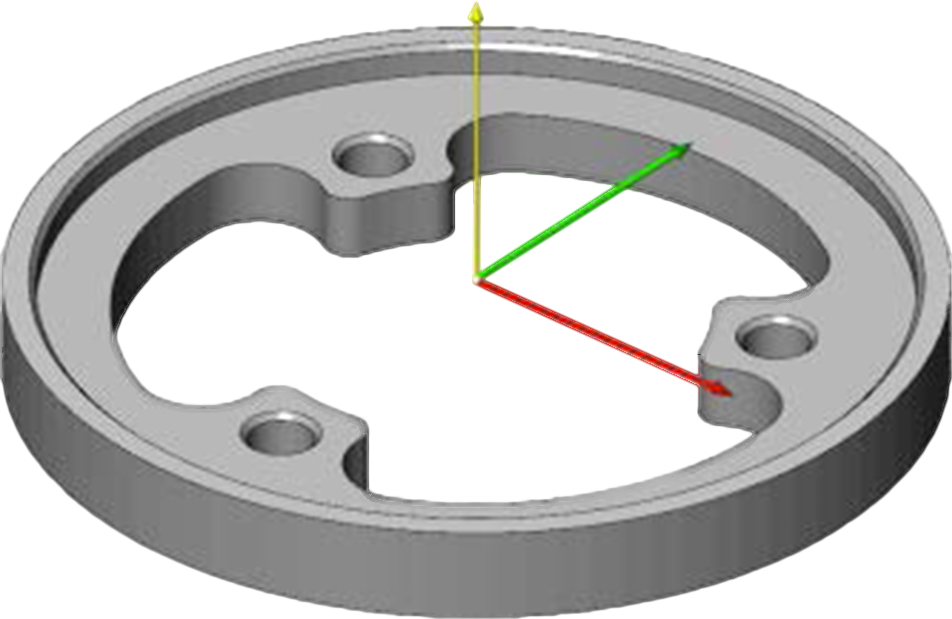

Now we have a closed contour, which we can also check again visually in the 3D view:

Now it’s your turn.

You will find more tips in the upcoming newsletters.

You have questions? Contact our experts using the contact form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Simulation of the IHK, German Chamber of Commerce, final examination Milling in Summer 2021(conducted in Germany) for Cutting Machine Operators

In this simulation, the examination task of the IHK final examination part 2 for cutting machine operators summer 2021 Milling is shown.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Practical Tip: Machining of Grooves – In Video Format

SYMplus™ offers you many possibilities to effectively implement your work. This also applies to the machining of “Grooves”.

Would you líke to learn how to machine grooves effectively? Watch this video to find out how.

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

PRACTICAL TIP – Vocabulary tests? Multiple choice tasks? This is how it works with SYMplus™

June 2021

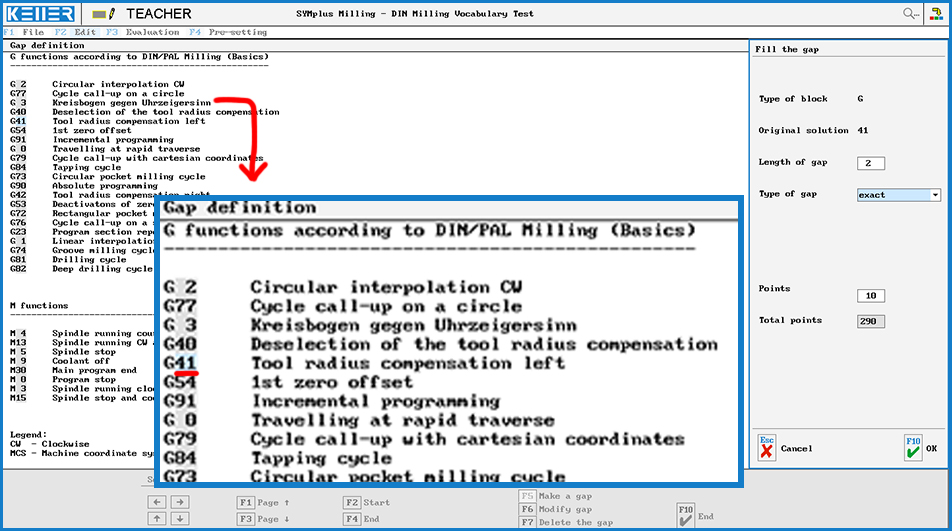

If you teach DIN/PAL programming using our SYMplus™ software, you are probably familiar with the “Teacher” mode of operation, which allows you to perform gap-filling tasks in the style of the written IHK(The German Chamber of Commerce) final examinations.

But what you may not know yet is that this mode gives you many more possibilities than just using an NC program as a basis.

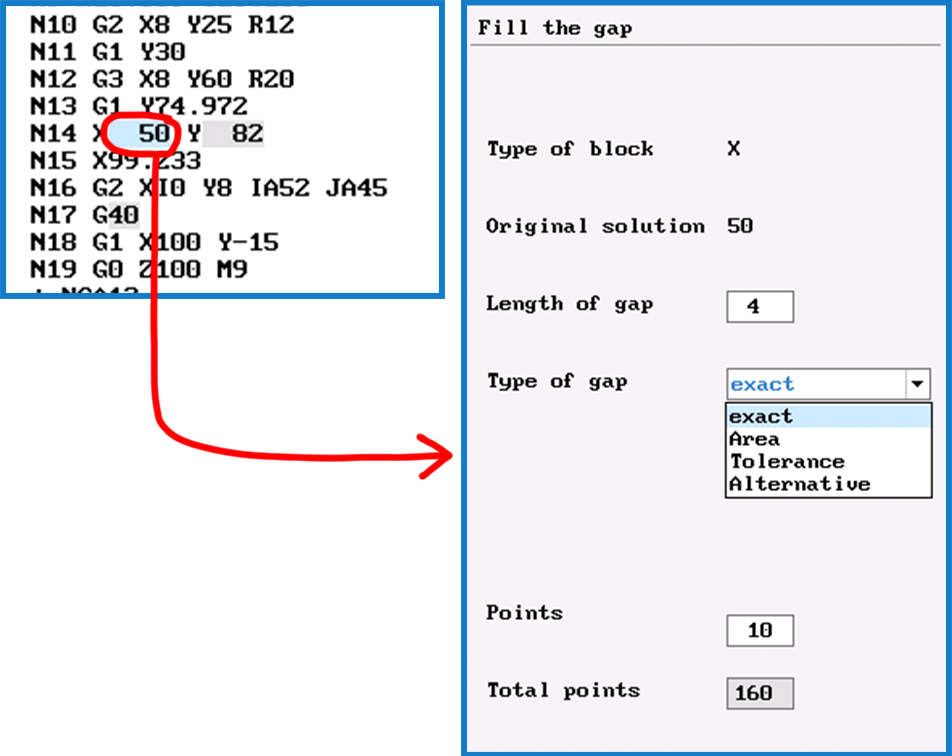

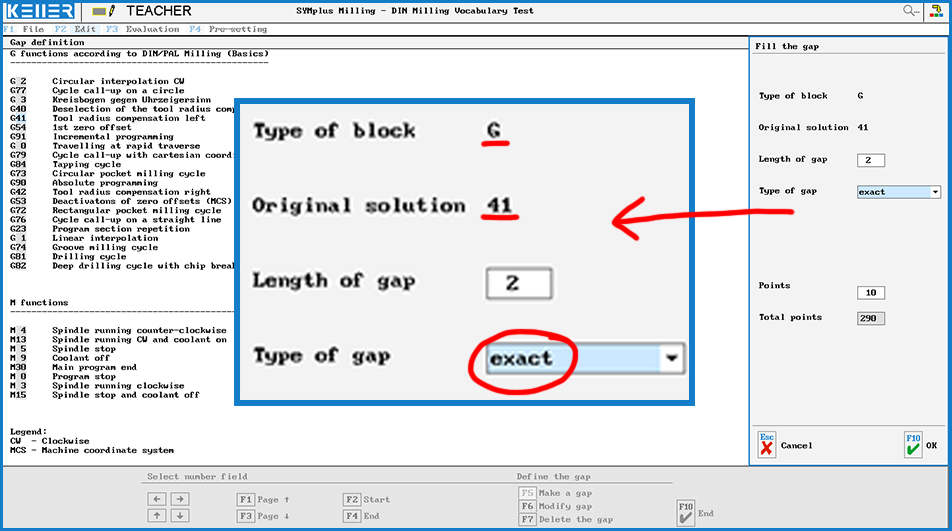

Reminder: The principle here is that you can define a gap in the NC program for each numerical value, which the students must later determine and enter either exactly or with a certain tolerance. Alternative entries are also possible, for example M13 as an alternative to M3.

Exactly the same principle works with any other text file. No matter whether PAL program or HEIDENHAIN program or something completely different. Because they can all serve as the basis for an exercise or an examination task.

When you realise this, it suddenly opens up a whole lot of new possibilities. So, for example, you can also create text tasks with multiple-choice solutions or calculation tasks (cutting data, production time, etc) with SYMplus™ and evaluate them automatically.

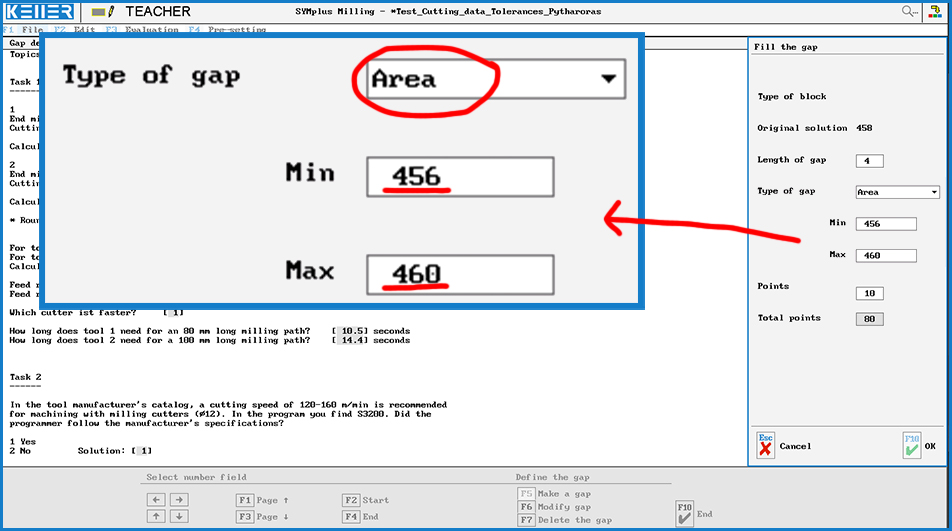

In this picture, for example, you can see a vocabulary test on G and M functions:

In this example, an exact gap is created at the position “G41”. This means that there is only one correct answer.

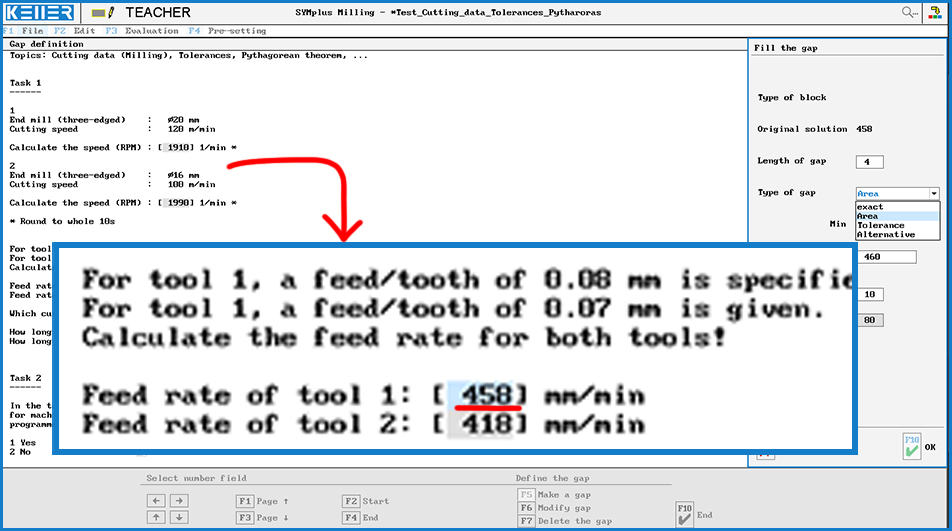

And in this picture you can see a class assignment with mathematical or text problems:

Here, a range of 456 mm/min to 460 mm/min was defined for the feed rate of the cutter as a response.

Now it is your turn. Try this out by yourself.

You will find more tips in the upcoming newsletters.

You have questions? Contact our experts using the contact form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Newsletter May 2021

KELLER.Software Training Initiative

Exam preparations will soon come to an end. This month the IHK(Chamber of Industry and Commerce) final exam part 1 of the cutting machine operators (conducted in Germany) will take place. We wish all trainees the best of luck.

But not only will the exams be over, but also our -now more than one year- running offer “all students get the free student version, no matter if the school/company is a customer of KELLER.Software or not” will end. There have been three final exams during this time and KELLER.Software feels glad to have supported all examinees with this offer. After the current exam this action will expire. This means that from June 1, 2021 all free licenses will be disabled.

Don’t worry though, we have something new for you: The KELLER.Software Training Initiative.

What is the KELLER.Software Training Initiative?

This is a support for all trainees, which makes it possible to book the student version for one year. And it’ even free of charge until 31.12.2021.

For this you only have to fulfill 3 criterias:

- You must be in possession of SYMplus™ with a running plusCARE™ contract.

- You must send us an application with “Expiry date 2021” by e-mail or by form.

- Your students must then re-apply by naming their customer number on the form below. Applications that do not include the customer number or that do not use the form will be ignored.

Re-register via this form > https://cnc-keller.com/buy-symplus/

You are not yet a plusCARE™ customer?

Then contact us now> https://cnc-keller.com/keller-contact/

We have often written that it is our claim to be the best support in your daily CNC everyday life. To ensure that we can continue to live up to this in the future, we have put all our expert knowledge into the new SYMplus™ Update 60, which is now available to all customers with plusCARE™.

This is what’s new as of Update 60> https://cnc-keller.com/symplus-support/new-features-optimizations/

You need help with the Software Update?

Our support will help you > http://cnc-keller.yoursupport.de/cnc.en/search?q=KELLER+update+manager+

We wish you a beautiful day ahead.

– Your KELLER.Software-Team

Practical Tip: Machining of Grooves

SYMplus™ offers you many possibilities to effectively implement your work. This also applies to the machining of “Grooves”.

To learn more about the Tip of the Month, please click on the picture below:

Much more from KELLER.Software…

Upcoming Training Sessions:

03.-04. June. 2021: Driven tools, plane swing and reform PAL2020

17.-18. June. 2021:Basics of graphic programming (CAD/CAM) with SYMplus™.

Further Information>https://cnc-keller.com/keller-academy/

Be it a new software update, a new promotion from us or interesting looks behind the scenes of KELLER.Software, if you follow our social media channels, you will always be the first to hear the news.

LinkedIn > Facebook > Instagram > Xing >

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

PRACTICAL TIP – Machining of Grooves

May 2021

SYMplus™ offers you many possibilities to effectively implement your work. This also applies to the machining of “Grooves”.

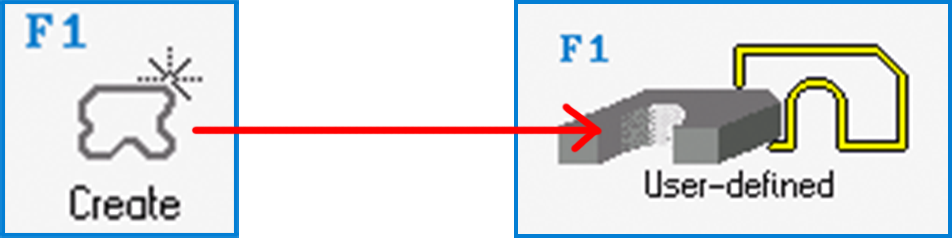

And this is how easy it is:

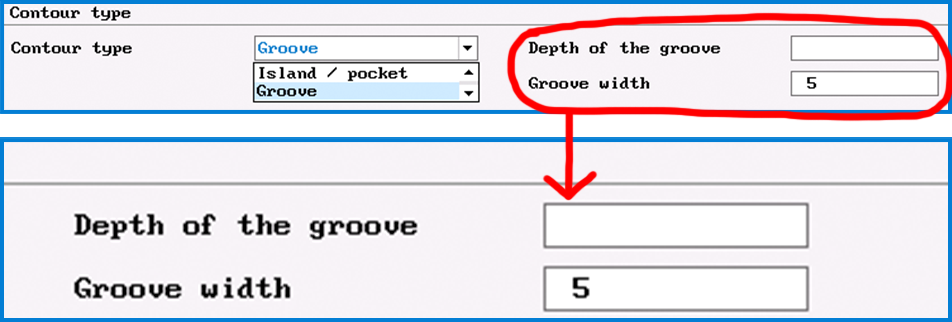

Open the “Geometry” mode in your SYMplus™ software. Here you first create the contour type “Groove” via F1 “Create” > F1 “User-defined”.

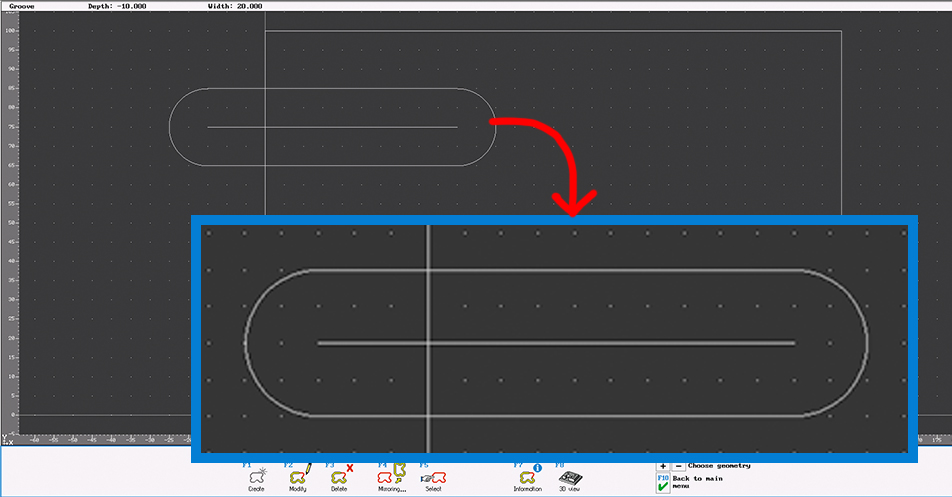

Initially, only the center path of the groove is described there, which in the simplest case is merely a straight line. The outer contour is determined by the groove width, which is entered together with the depth of the groove, right at the beginning of the creation process.

You can also create an open groove. In this case, however, you should make sure that the starting point of the groove is outside the workpiece, as this point is also automatically used as the starting point for the machining operation when machining with the “Groove” step.

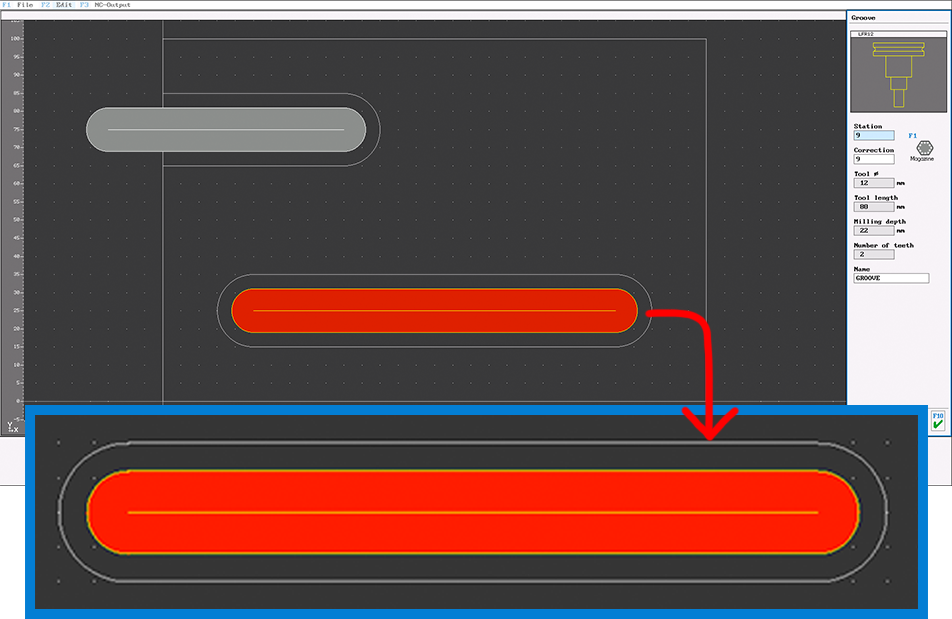

Then switch to the “Work plan” mode of operation. There, also select the “Groove” step so that the tool also follows the center path here, as created in the geometry – regardless of whether the tool diameter is smaller than or equal to the groove width.

If you select a small tool, a correspondingly large amount of contour allowance remains.

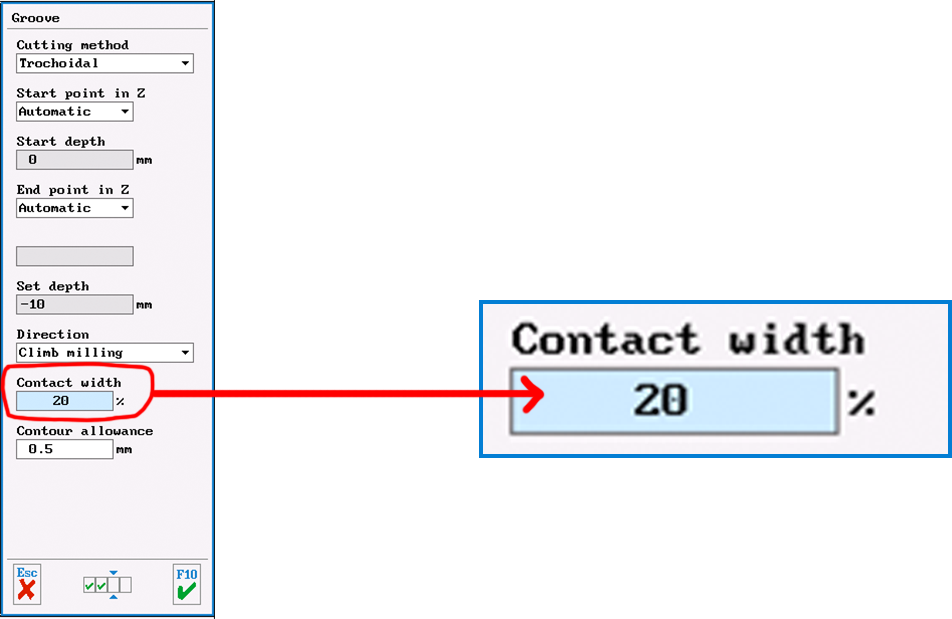

If you have created a groove that is twice as wide as the tool diameter, you can switch the “Cutting method” to “Trochoidal” (whirl milling) on the third dialog page of the “Groove” step. Then – taking into account a contour allowance – the groove is rough-milled over its entire width. When doing this, also make sure to set the “contact width” to a sensible value (e.g. 20%).

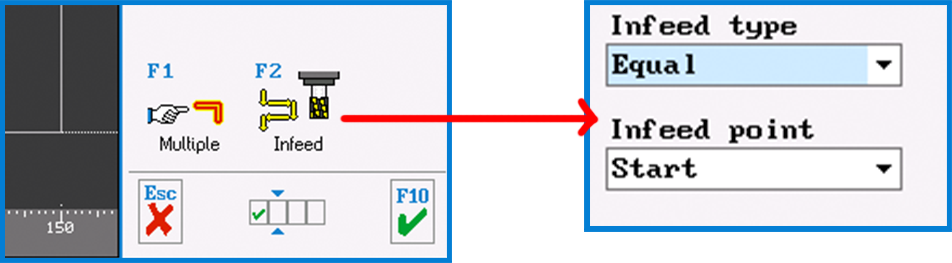

However, if you enable an end mill (which usually does not cut across the center) for ” Groove/Engrave” machining, you can also machine an open groove with this tool. Then set the “Infeed type” to “Equal” and the “Infeed point” to “Start”.

In principle, you can also machine a groove using the “Surface” step. This also applies in particular if the outer contour rather than the center path was designed in the geometry or if only the outer contour of the groove could be transferred from a CAD file. The “Surface” step always works if the tool diameter is smaller than the groove width (if necessary, smaller than the groove width minus 2x contour allowance).

To machine a closed groove with an end mill (without center cut), you can also use the “Surface” step. In this case, however, you must switch the infeed to “Ramp” on the fourth dialog page, because the groove is too narrow for the usually preset helical plunge. Only after this change is the groove recognized as a possible surface to be machined and displayed in red.

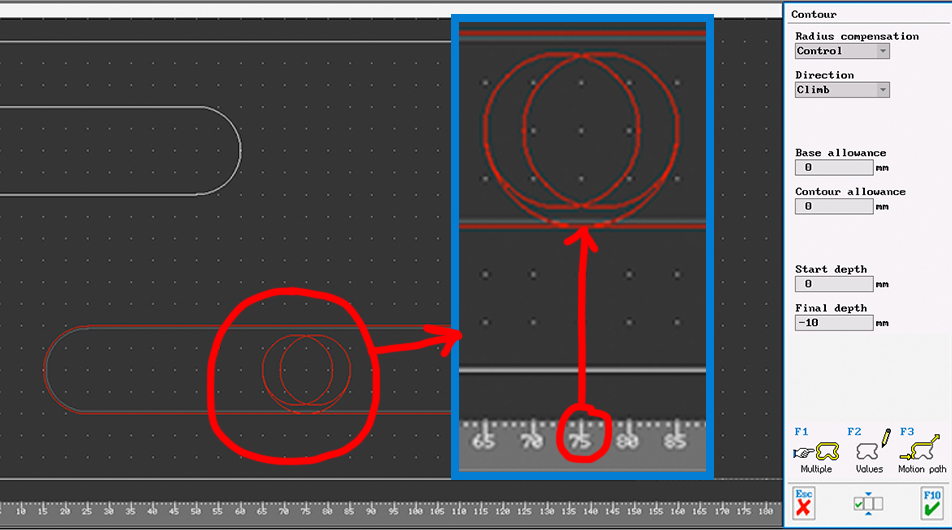

After roughing (work step “Surface”), the edge of the groove can be finished normally like a pocket via the work step “Contour”. Since by default only the transition points between contour elements (i.e. here between the straight lines and the semicircles) can be selected as approach and departure points, the point has been set to the center of the straight line (here X75) via X value on the contour.

Now it is your turn. Try this out by yourself.

You will find more tips in the upcoming newsletters.

You have questions? Contact our experts using the contact form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

SYMplus™ Update 60

With lots of brand new features and improvements, SYMplus™ Update 60 is available for all our customers with plusCARE™.

Would you like to know what improvements have been carried out? Here is the link for you: https://cnc-keller.com/symplus-support/new-features-optimizations/

You dont have plusCARE™ yet or do not know what plusCARE™ is and its advantages are? Head to our website to find it out and contact us:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Practical Tip: Ready for the island – In Video Format

Working with islands or tenons can be complicated. But with SYMplus™ this task is quite easy.

Watch our practical tip video to see how easy it is.

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

PRACTICAL TIP – Ready for the Island

April 2021

Working with islands (or tenons) can get complicated. However, with SYMplus™ this task is quite easy.

And this is how easy it is:

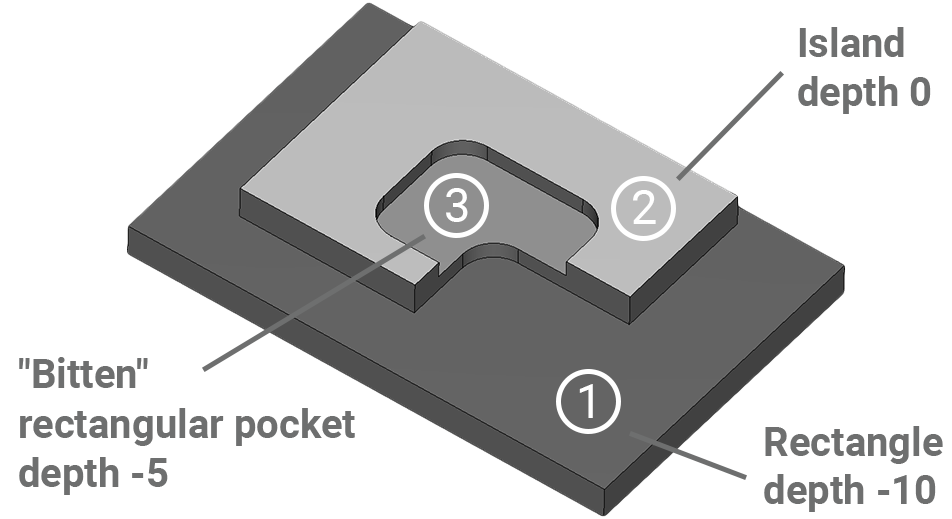

You want to manufacture the following workpiece and for this purpose you first create it in the “Geometry” operating mode.

This workpiece is composed as follows:

- From a rectangle on the depth -10

- On it an island (light gray) with the depth 0

- A “bitten” rectangular pocket in the islands at depth -5 (however, this pocket must also be constructed like the light gray surface with 6 lines and then 4 curves, so that the contours are partly on top of each other).

In SYMplus™ we understand the depth/height of the surface not as the traverse depth of the tool but as the depth or height of the surface circumscribed by the contour. It is important that each contour is closed. To check whether you have done everything correctly, you can look at the 3D image of the workpiece.

When you have created and saved the workpiece, switch to the ” Work plan” operating mode. There you first edit the rectangle at depth -10.

If you use the preset cutting type “Contour parallel” when creating the working step on the third dialog page, you will notice that the milling cutter makes full traverse paths and then only clears out the material with the set pressure width.

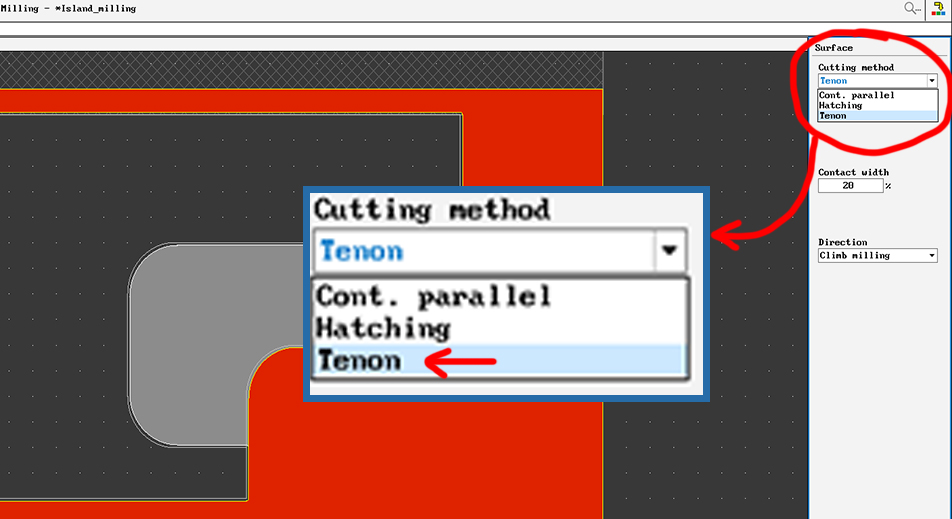

To prevent this, change over to “Tenon” for surface milling by one island.

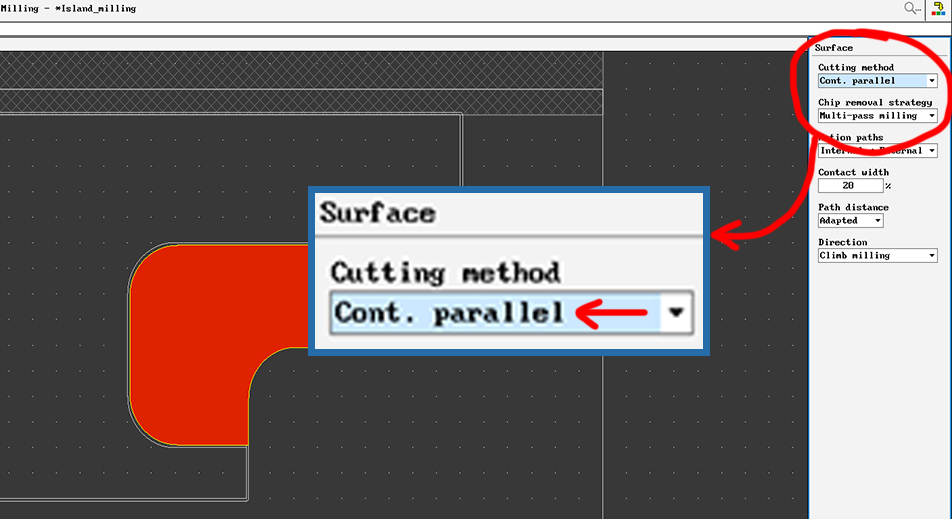

Since the island has a narrowing (or “port entrance”), a working step must also be created for this. To do this, as with a pocket, clear out with the machining type “Contour parallel”.

In the ” Work plan” you can easily try out alternatives to this machining strategy by undoing the work step and creating a new one. For example, you can place a groove in this narrowing and first machine it trochoidally.

Now it’s your turn. Try it out and see for yourself how easy it is to handle islands and tenons with your SYMplus™ software.

You will find more tips in the upcoming newsletters.

You have questions? Contact our experts using the contact form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Practical Tip – The Handwheel in the Work plan – In Video Format

In this video you will get a first insight into the “Handwheel” work step.

When could the “Handwheel” be used?

If, for example, you have to traverse a very special path with a special tool. Then it can happen that the automatic system, which normally simply takes the programming of the traverse paths off your hands, reacts differently than the expert imagines.

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!