RN & AS Addresses: Fillets, Chamfers, Taper Angles (Video)

In this video, we guide you step by step through Task 2 from the Christiani task collection “CNC Turning Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect in the video:

✅ Easy programming of fillets & chamfers with RN

✅ Define taper angles directly with AS – no manual calculation needed

✅ Efficiently creating turning contours with PAL G-code

Who is this video for?

Perfect for CNC programmers, machinists, and instructors looking to improve their G-code programming skills for CNC turning.

Subscribe to our channel to not miss out on more tutorials and tips:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Downtime in CNC production? Not with KELLER! (Customer Case Study)

Stuck with a tricky machining job and no solution in sight? One of our customers recently faced the same challenge…

❓The Problem:

Their CNC control system couldn’t handle two opposing 3-start flat threads on a stretch roller (Ø152, length approx. 3m). A costly delay seemed inevitable.

💡The Solution:

With SYMplus™, they got back on track—fast! A custom macro allowed them to rough and finish the threads using standard grooving tools in multiple small passes. No downtime, no hassle—just smooth production.

- Got a machining challenge of your own? Let’s solve it together!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Face Roughing, Longitudinal Roughing & Finishing (Video)

In this video, we guide you step by step through Task 3 from the Christiani task collection “CNC Turning Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect in the video:

✅ Face turning with roughing cycle G82

✅ Longitudinal roughing with G81 – defining depth of cut & allowances correctly

✅ Finishing the contour with radius compensation G42

Who is this video for?

Perfect for CNC programmers, machinists, and instructors looking to improve their G-code programming skills for CNC turning.

Subscribe to our channel to not miss out on more tutorials and tips:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

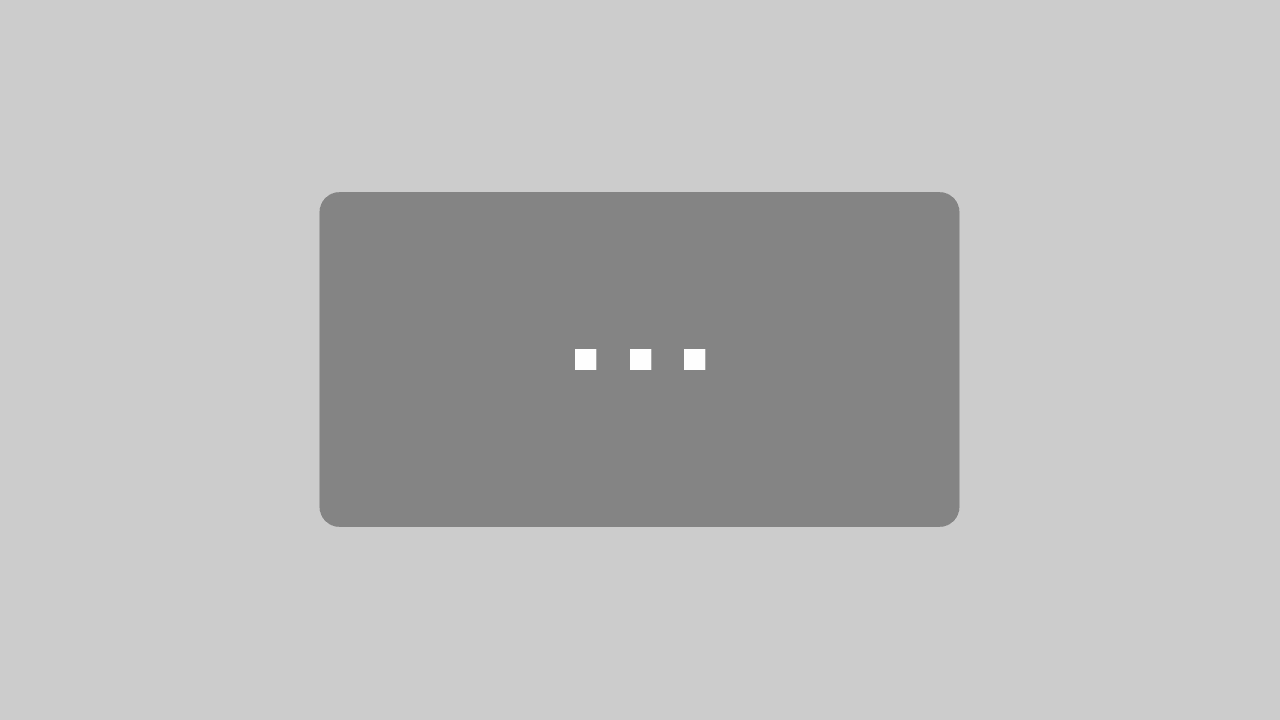

Create a real NC program from PAL G-code

Can I use programs written with PAL G-Code directly on the CNC machine with your software? – We get asked this question quite often. Answer: Yes, you can!

With SYMplus™, you can transfer your PAL program to the machine in just a few easy steps:

1️⃣ Generate the NC program – Simply select the appropriate controller, e.g., SIEMENS, HEIDENHEIN, or HAAS, and choose the storage location.

2️⃣ Transfer the program – Via network, USB, or serial interface.

3️⃣ Final test on the controller – Use the simulation graphic to check if everything is correct.

Done! This is how a PAL program becomes real CNC production!

- To see exactly how it works in SYMplus™, watch our video here: https://youtu.be/ANzvcVRnPso

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Outer Contour, Slot Milling & Square Pocket (Video)

Now on YouTube! 🎥🎞️🔴 In this video, we guide you step by step through Task 11 from the Christiani task collection “CNC Milling Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

What to expect in the video:

▶️ Milling of the outer contour and circular contour

▶️ Detailed processing of pockets

▶️ Side pockets (efficient use of subprograms)

▶️ Fast and precise slot milling

▶️ Square pocket (easily implement complex geometries)

▶️ Centering, drilling, and tapping

This video is perfect for CNC programmers, machinists, and trainers looking to improve their skills in processing complex geometries and techniques.

Subscribe to our channel to not miss out on more tutorials and tips:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Milling Inclined Grooves: “Irregular” Cartesian Coordinates (Video)

Now on YouTube! 🎥🎞️🔴 In this video, we guide you step by step through Task 6 from the Christiani task collection “CNC Milling Technology according to PAL2020”. Thanks to our 3D simulation in SYMplus™, everything is explained clearly and understandably.

This task includes:

▶️ Milling inclined grooves

▶️ “Irregular” Cartesian coordinates (G1 X Y, G3 X Y I J / R)

▶️ Multiple drilling points on a circular arc, G77

Subscribe to our channel for more CNC tutorials:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

3 Steps to Rotary-Symmetric Contour!

For pocket or island contours, the entire geometry often needs to be created from A to Z. But what about rotationally symmetric contours? That should be much simpler, right?

With SYMplus™ CNC software, you can do it in just 3 quick steps:

1️⃣ Create 1/6 of the contour – saving you time and effort.

2️⃣ Mirror the created section – now you have the other side.

3️⃣ Mirror and rotate the whole thing around the other axis – and voilà, your rotationally symmetric geometry is complete!

- Want to see how it works in detail? Watch the video where we explain the entire process step by step: https://youtu.be/KPhNBtI_bHU

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

First KELLER.Academy course 2025 was a great success!

The first KELLER.Academy course of 2025 was a great success!

In one and a half intense days, the participants learned all about the basics of PAL programming with SYMplus™ and were able to directly apply their knowledge in hands-on exercises.

Congratulations on successfully completing the KELLER.Academy course! Thank you for your participation and the great exchange of ideas.

The participants:

Berufskolleg der Stadt Bottrop

Robert-Limpert-Berufsschule Ansbach

Goldhofer AG

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

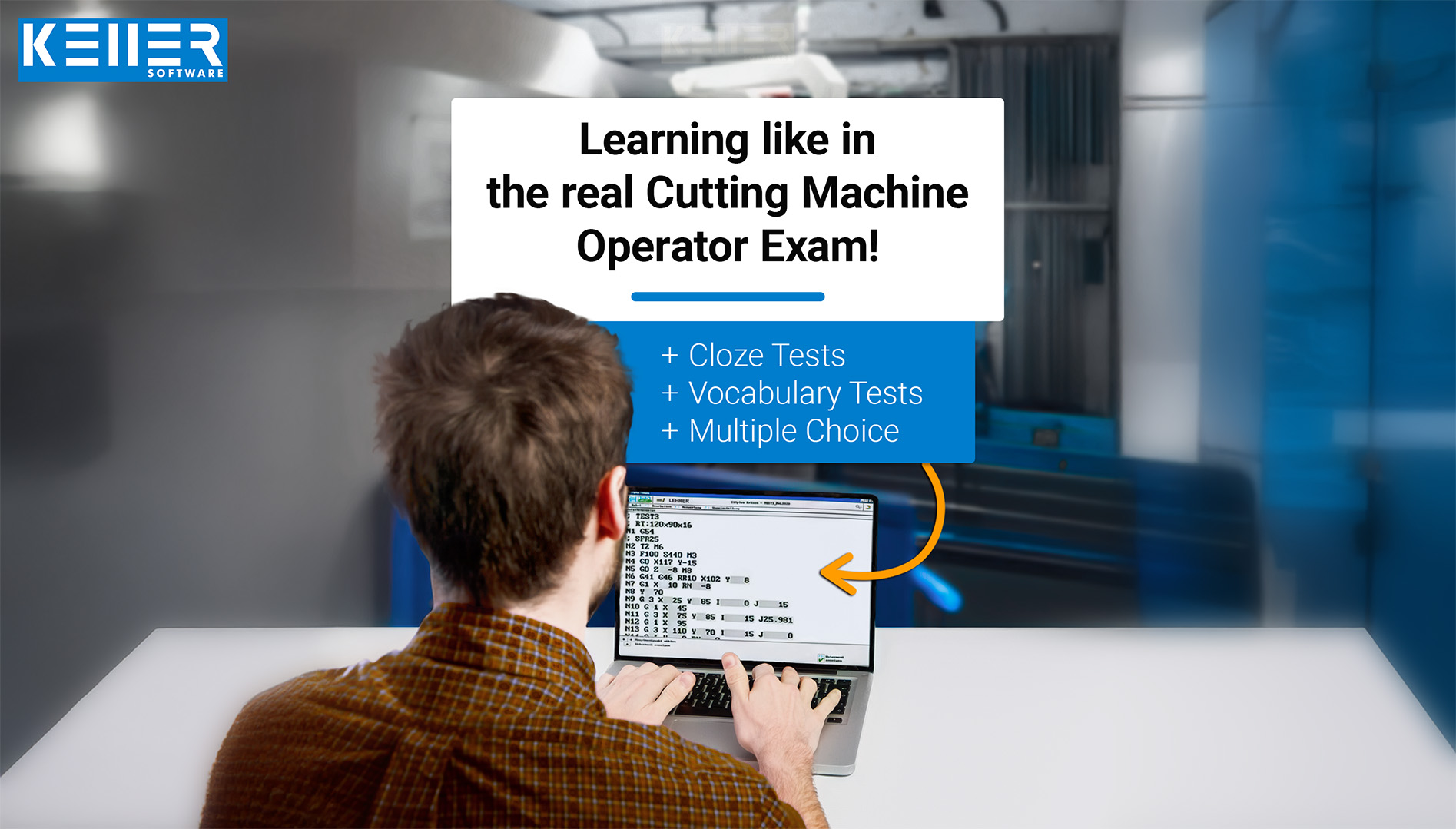

Learning like in the real Cutting Machine Operator Exam!

Learning like in the real Cutting Machine Operator Exam – here’s how with SYMplus™ CNC software!

✅ Create vocabulary tests and multiple-choice questions in no time.

✅ Offer exam-like exercises: Simulate fill-in-the-blank tasks.

✅ Efficient feedback: Instant evaluation and targeted support for trainees.

No extra effort, just smart features directly in SYMplus™!

- See how easy it works with SYMplus™ here: https://youtu.be/D5FngKoU1Qo

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

The Most Important CNC PAL Commands (Turning/Milling) – Free Download

Did you know? We offer posters with all the essential CNC commands for milling and turning completely free – based on the German learning standard (PAL) – perfect for your workshop or classroom!

✅ All relevant commands at a glance

✅ Supports daily work and training

✅ Ideal for trainees – but also for professionals

Download for free now and stay on top:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!