KELLER.Academy – Basics of DIN/PAL Programming with SYMplus™

Last week’s KELLER.Academy course was on the topic “Basics of DIN/PAL Programming with SYMplus™” We congratulate the participants from BBS Cuxhaven and Aptiv for the successful completion of the course and we thank you for visiting us.

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

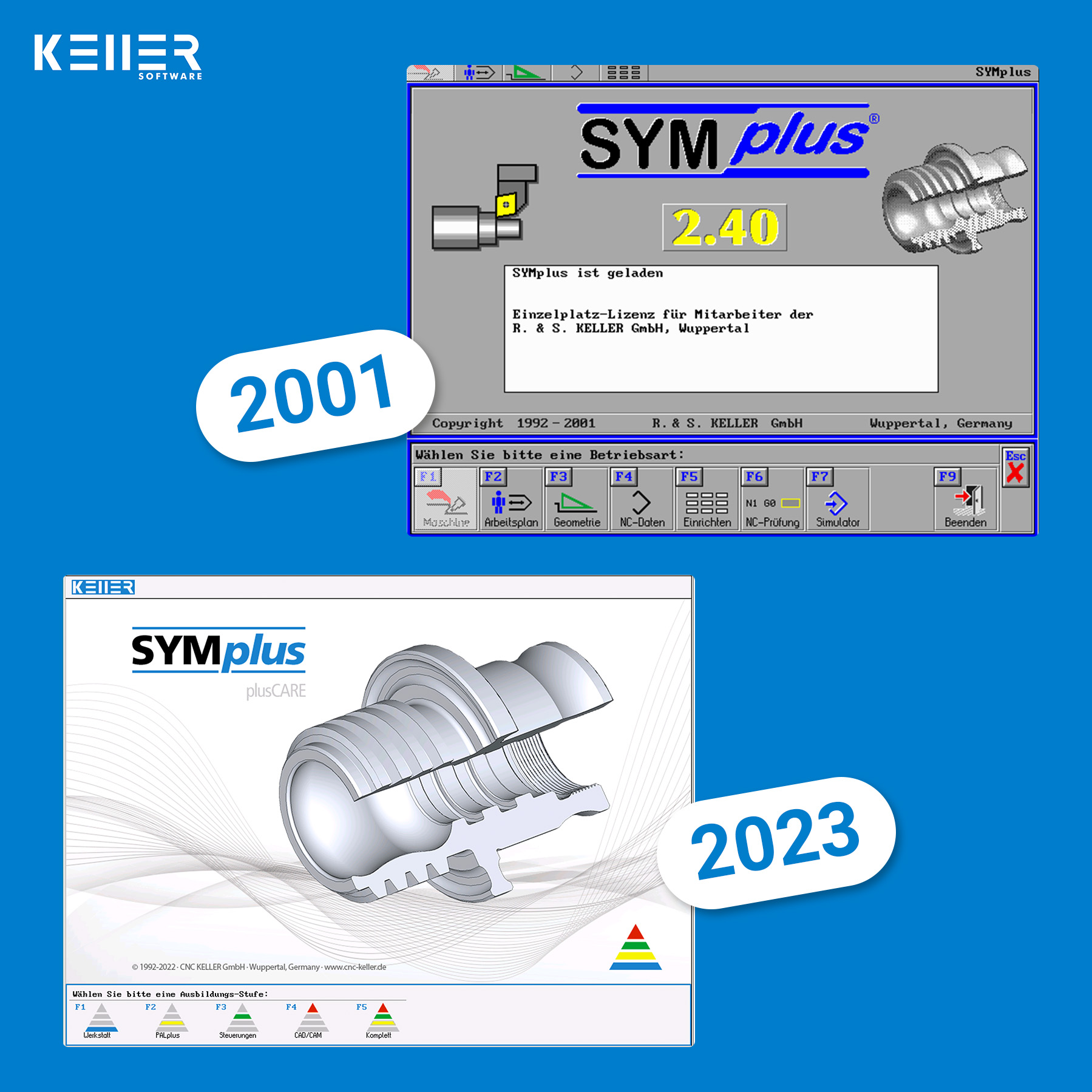

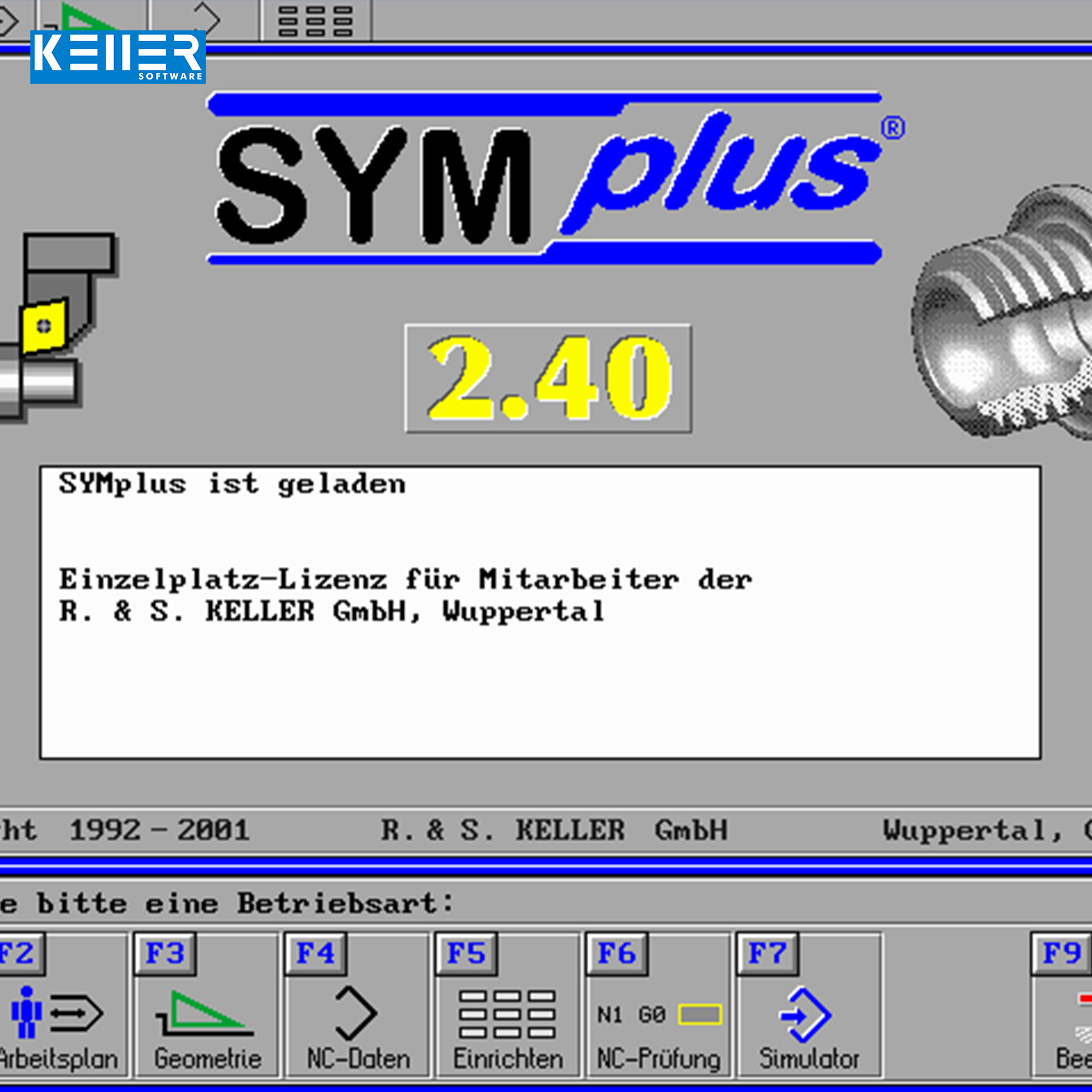

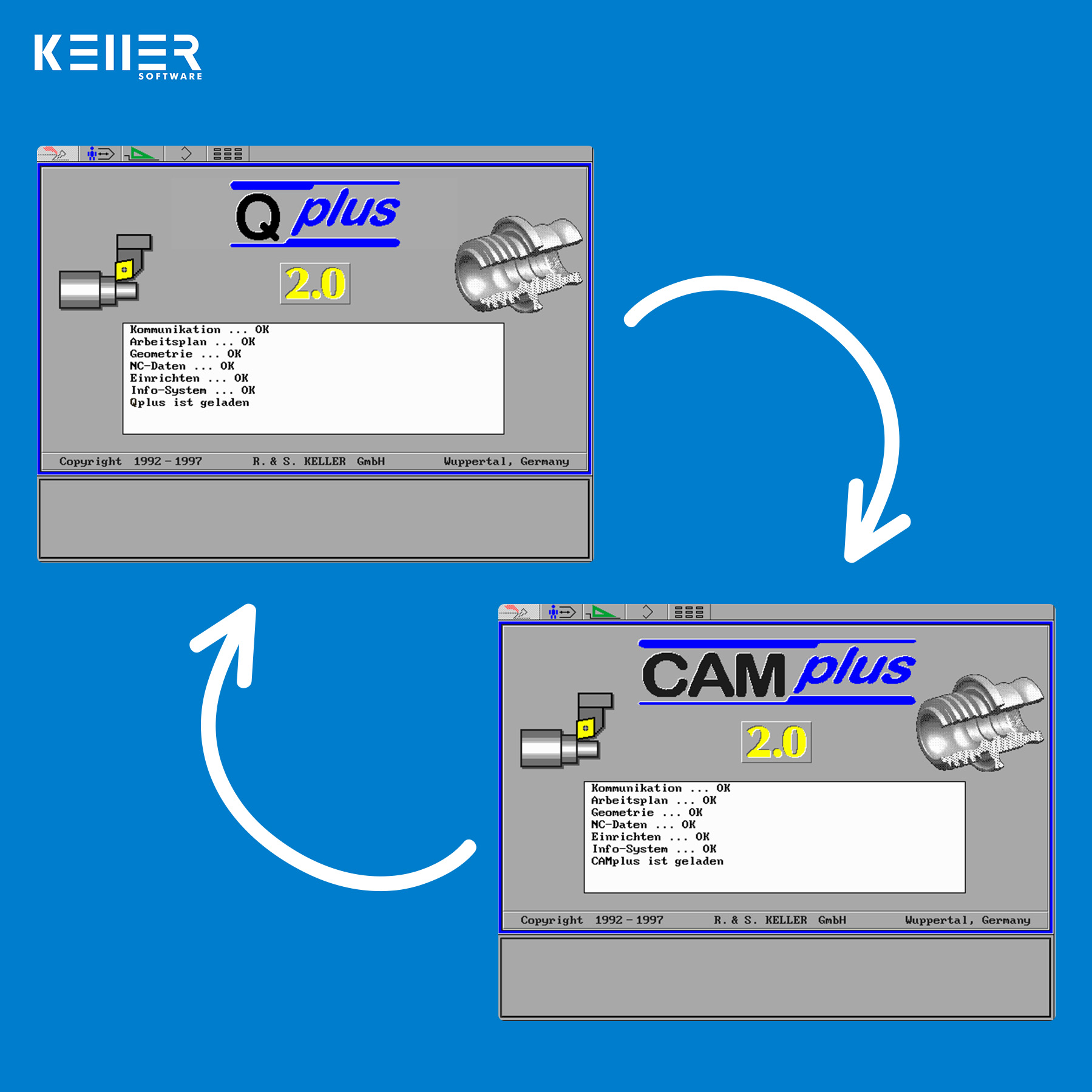

Throwback 2001 – SYMbiosis of learning and manufacturing

On this #ThrowbackThursday, let’s travel back in time to 2001, when our software underwent a groundbreaking transformation! After the turn of the century, our former softwares “Qplus” (for training) and “CAMplus” (for production) transformed into our enduring CNC software “SYMplus” – the perfect SYMbiosis of learning and manufacturing.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

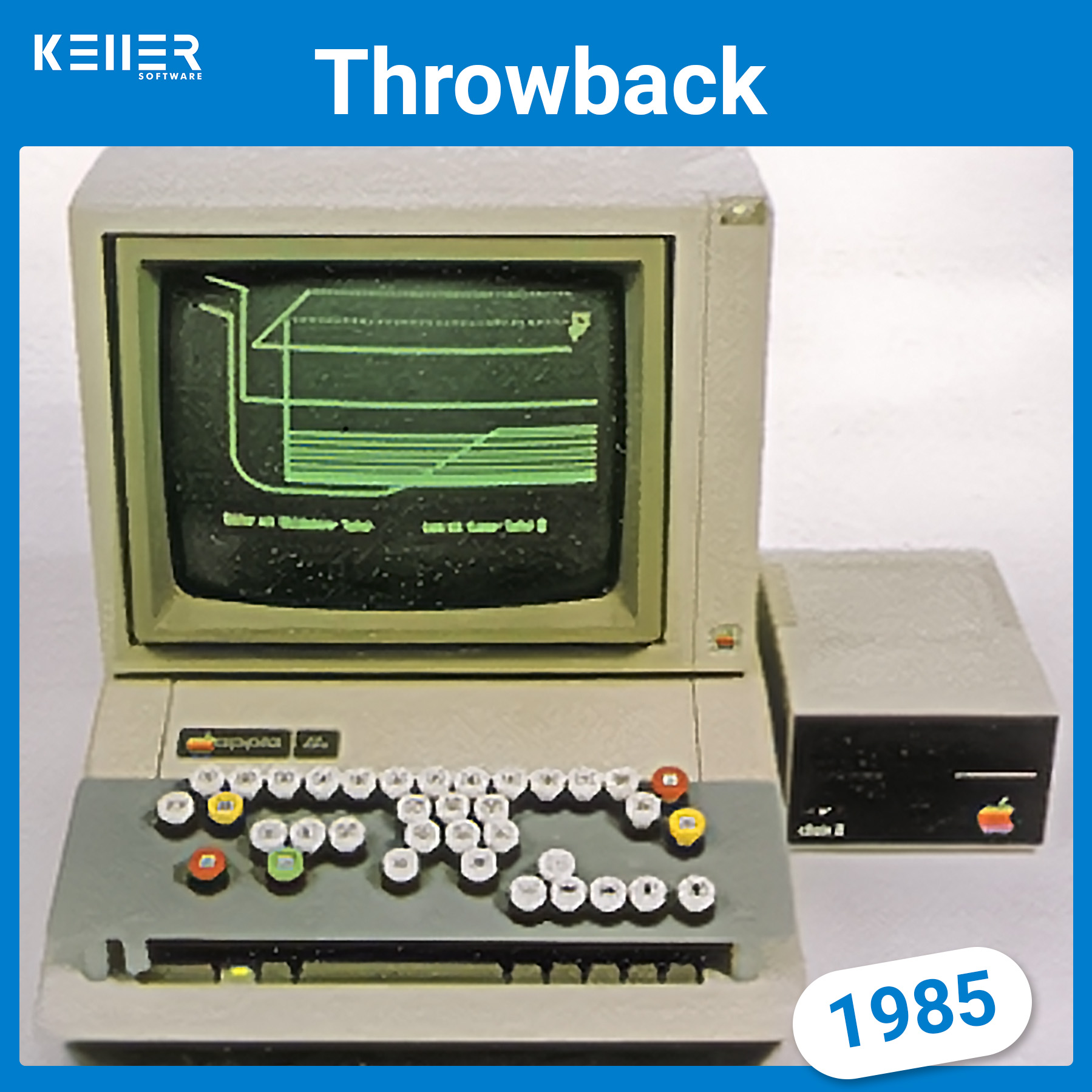

Throwback 1985 – KELLER in newspaper

On this #ThrowbackThursday, let’s travel back to 1985. KELLER.Software developed the EPL1 Simulator on the Apple 𝘐𝘐e – fun fact: at that time, only 64 kB RAM was available! The EPL1 keyboard was meticulously handcrafted and was a special attachment for the Apple 𝘐𝘐e, providing an almost identical control experience to the original. Pretty cool, isn’t it?

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Practical tips as videos on YouTube

Have you seen our practical tips videos on YouTube?

Click here https://www.youtube.com/@CNCKELLERGmbH or search for “CNC KELLER GmbH” on YouTube to find us.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Training at the KELLER.Academy – Basics of graphical programming (CAD/CAM) with SYMplus™

Summer vibes: Training mode activated!

Last week, we had our “Fundamentals of Graphic Programming (CAD/CAM) with SYMplus™” course and welcomed two great companies to it: Hirschvogel Eisenach GmbH and APTIV Services Deutschland GmbH. It was a pleasure to host you. We look forward to your next visit.

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

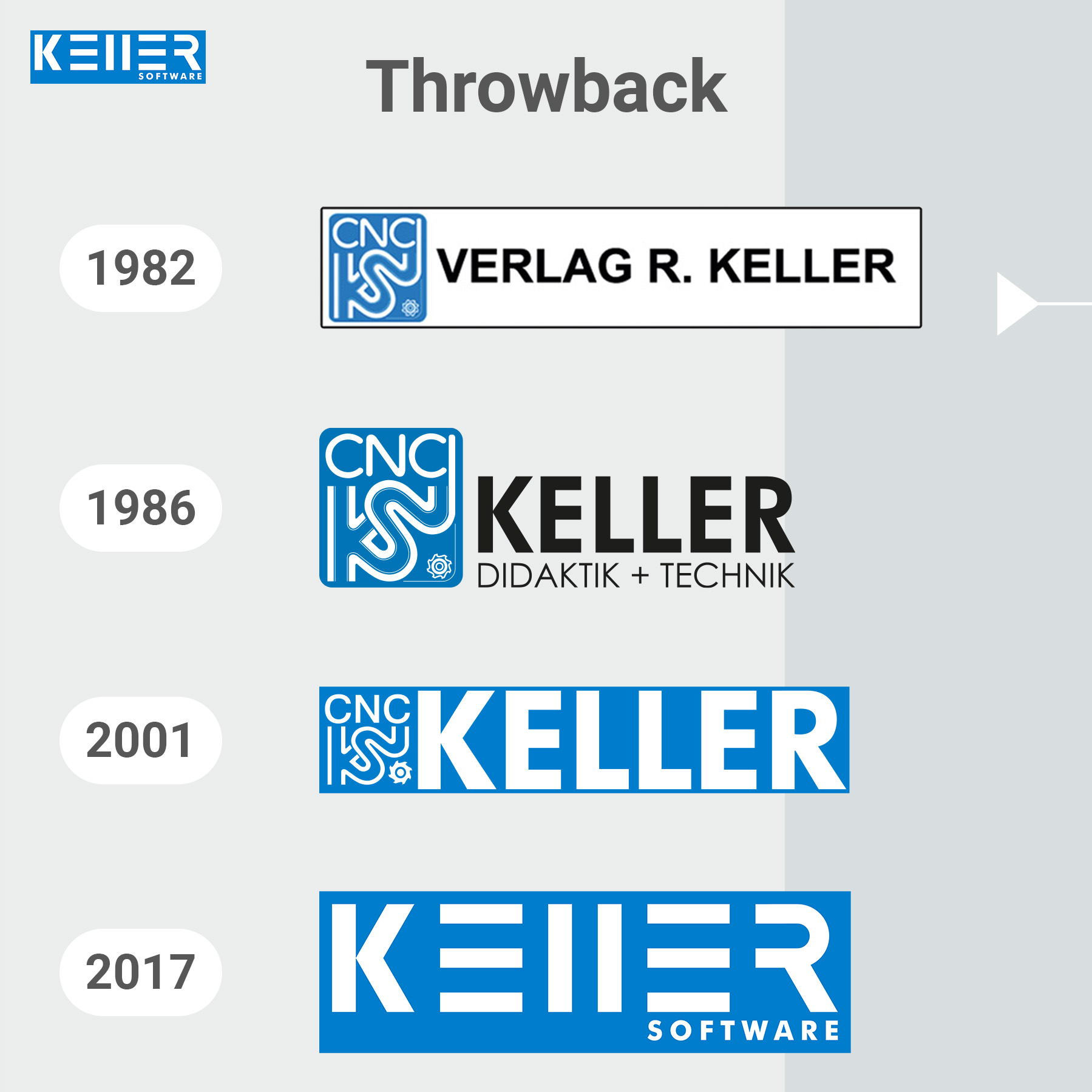

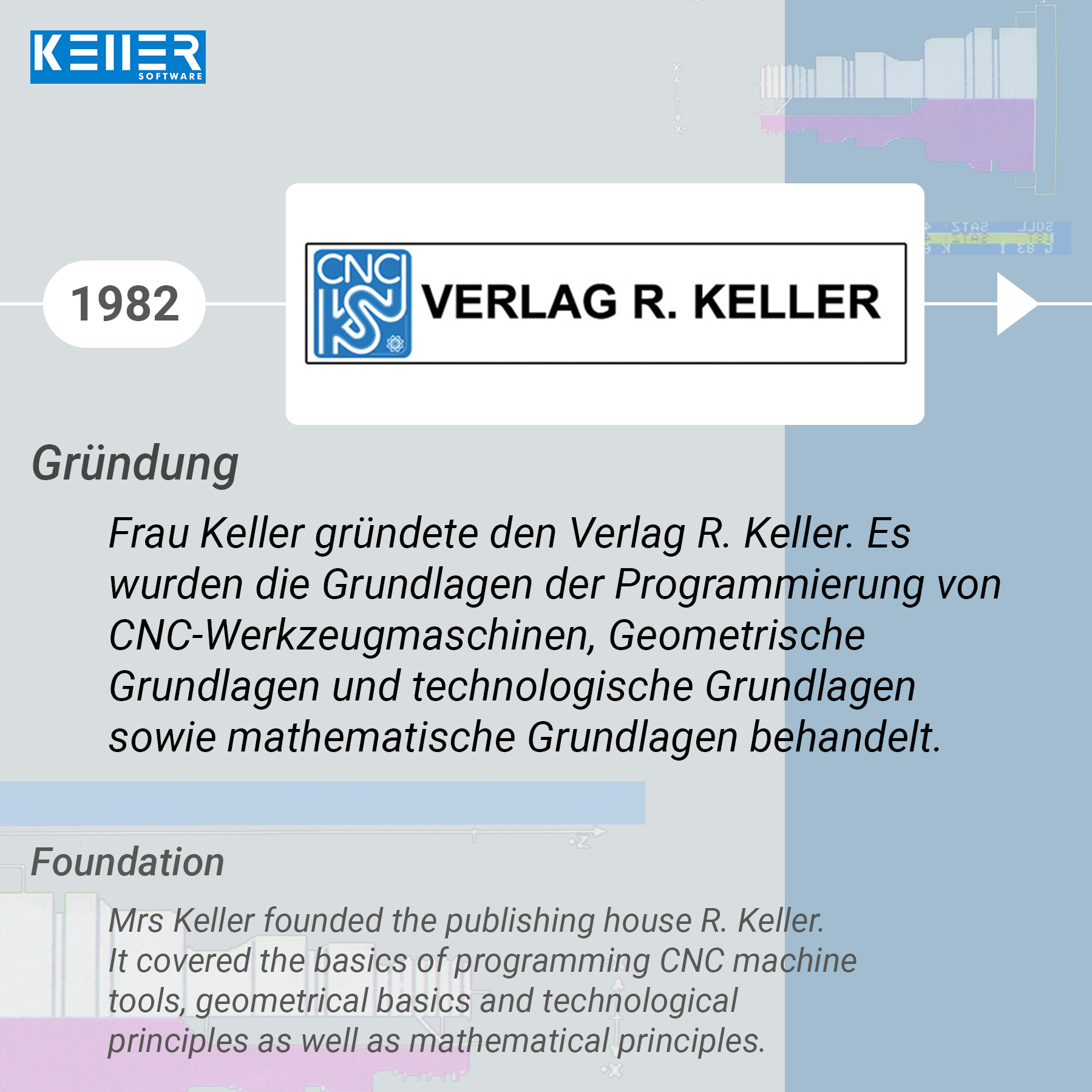

KELLER logo then and now

On this #ThrowbackThursday, we’re diving into the legendary KELLER logo. We’ve stayed true to ourselves over the years, and the “KELLER Blue” still adorns our logo.

Which version of the KELLER logo did you first come across? Most of you are probably familiar with the 2001 version, right?

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Your feedback matters: Have a say in the next webinar topics.

We’re excited to announce that following the tremendous success of our “PAL2020” webinar, we’re now seeking your input to make our future webinars even better!

If you can understand German and would like to contribute, we invite you to take part in our short survey. Your feedback will play a crucial role in shaping the topics we cover. The survey is Anonymous.

- Access the survey by clicking here: https://www.surveymonkey.de/r/M8BTTS9

Thank you for your understanding and support in shaping the direction of our upcoming webinars!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Newsletter June 2023

Unlocking New Horizons: Explore the PAL2020 Webinar Recording and IHK Exam Innovations

If you have missed our webinars on the topic of “PAL2020: What’s changing in the cutting machine operator exam” or would like to review the content again at your leisure, then we have great news for you. As of now, the webinar recording is available to everyone free of charge!

Please note: Webinar Recording is currently available only in German language.

The Webinar covered the following topics:

- Changes in past IHK exams

- Innovations that are coming in the future and how they will be incorporated into the exam

- How to transfer old programs to the changed coding

- How your students can prepare for the fill in the blank tasks

- “Debriefing” of the final exams for cutting machine operators in May

How can you get the webinar recording?

Type https://pal.cnc-keller.de into your browser and register yourself on the page, and we will send you the link to the recording via email.

Since the beginning of the year, we have hosted this webinar once or twice a month. With a total of 18 events, we received a great response. A participation rate of 80% is something we’re very pleased about.

Your KELLER.Software team wishes you a relaxing vacation, sunny days and/or just a nice summer time!

– Your KELLER.Software Team

Much more from KELLER.Software …

Next Appointments in the KELLER.Academy:

Driven tools, level swivel and reform PAL2020

- 13.-14. July 2023

- 24.-25. August 2023

Basics of graphical programming (CAD/CAM) with SYMplus™

- 27.-28. July 2023

- 07.-08. September 2023

Basic DIN/PAL programming with SYMplus™

- 10.-11. August 2023

- 21.-22. September 2023

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

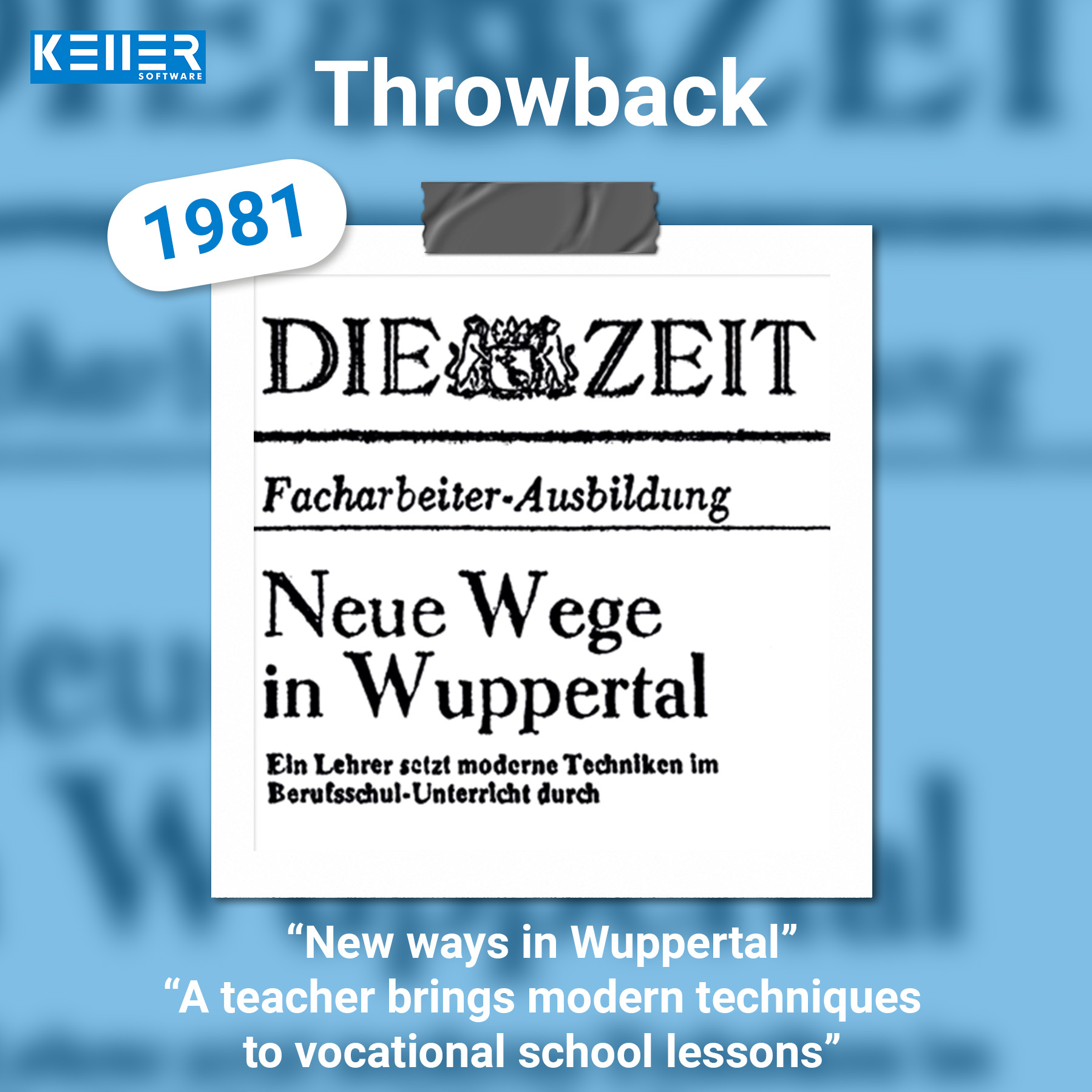

Throwback 1981 – KELLER in newspaper

On this #ThrowbackThursday, we’re whisking you away to the year 1981 for a glimpse into the early days of “KELLER”. Back then, our visionary founder Siegfried Keller was making an impact as a dedicated teacher at an industrial school, yet the seeds of “KELLER” were already sown.

Check out this captivating headline from the August 1981 issue of “Die ZEIT” newspaper, which proves the early existence of “KELLER”: “New ways in Wuppertal. A teacher brings modern techniques to vocational school lessons”. (The article is in German, by the way!)

Today, we celebrate our roots and honor the journey that has led us to where we are now. It’s remarkable how “KELLER” has evolved over the years. Here’s to progress, passion, and the enduring spirit of innovation!

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

International Day Against Homophobia 2023

Today, in honor of the International Day Against Homophobia 2023, our CNC software SYMplus™ is shining brightly in the vibrant colors of the rainbow – Together for Acceptance and against discrimination.

As we head into the long weekend, the KELLER.Software team wishes you a happy and colorful holiday! We’ll be back on Monday, May 22nd, ready to tackle your software needs with renewed energy and enthusiasm.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!