INSTANT CNC – new video on YouTube

Our brand new “INSTANT CNC” Video Series is now online on YouTube. A new video has been added to this series today. Have a look.

In this video, you will see a simulation of the exercise task 3 from Christiani’s booklet “Collection of tasks on CNC technology milling according to PAL2020” simulated with the CNC software SYMplus™.

The exercise task deals with: Pocket cycles, Groove cycles and drilling patterns (G72, G73, G74, G75 as well as G81 with G67 and G77).

Here is the link to the video: https://www.youtube.com/watch?v=TWWaNqezP7c

Additinally, the video from last week, the one that was available only in German then, is now also available in English. Here is the link to that: https://www.youtube.com/watch?v=18oOWc7MCWc

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

INSTANT CNC – new video format on YouTube

What’s new, you ask? The answer is “INSTANT CNC” – your little bite of “CNC” ready to enjoy in no time! This is our brand new Video format, mainly meant for our YouTube Channel.

As a German company, naturally our first video is also in German language. Do not worry though, we are working on the English one already and it will soon come your way. The first video in this series is a task from the Christiani booklet “Task collection CNC technology milling according to PAL2020”. With the help of an illustrative simulation from our SYMplus™ CNC software, we explain what this task is about. Further exercises from this booklet will follow.

Here is a link to the video:

https://www.youtube.com/watch?v=F61d7DvBfY4

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Practical tips as videos on YouTube

Have you seen our practical tips videos on YouTube?

Click here https://www.youtube.com/@CNCKELLERGmbH or search for “CNC KELLER GmbH” on YouTube to find us.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Software on YouTube

Check out CNC KELLER GmbH on YouTube! Simply search the name “CNC KELLER GmbH” or enter https://www.youtube.com/@CNCKELLERGmbH in your browser window.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

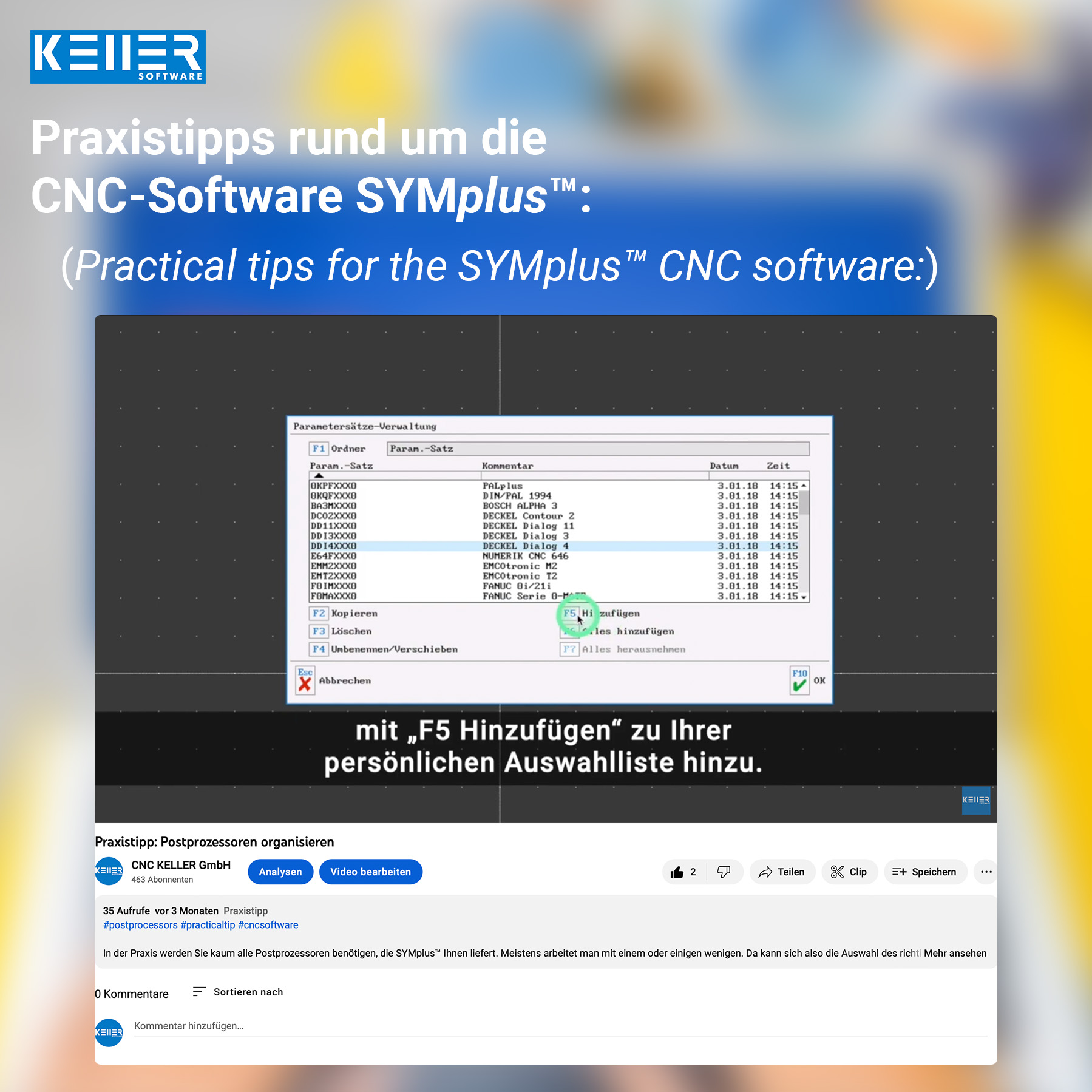

Practical Tip: How to organise Postprocessors – In Video format

SYMplus™ provides a list of around 50 Postprocessors. In reality, you will hardly ever need all of them. Mostly you work with one or a few. So selecting the right postprocessor can prove to be a nuisance with such a large list. Here is a tip that can help you organise those Postprocessors efficiently: Create a second folder for postprocessor parameter sets, and copy the postprocessors you currently need into this folder. That’s it.

In this practical tip, you will see how this works:

Follow KELLER.Software on YouTube to learn more:

https://www.youtube.com/CNCKELLERGmbH

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Practical Tip: Rewrite old PAL programs for the PAL2020 – In Video format

With the PAL2020 reform, some of the commands in the PAL coding were changed. The commands were changed so that programs written after PAL2008 or PAL 2012 will no longer run and lead to any error messages in the newer PAL2020 simulators (or PAL2020 C/Y or PAL2020 3+2). This means that you have to rewrite the program blocks almost completely – and that takes time.

A faster way to do this is to use the “Find/Replace” trick:

Follow KELLER.Software on YouTube:

https://www.youtube.com/CNCKELLERGmbH

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Practical Tip: From PAL programming to chips – In Video format

The phrase “From PAL programming to chips” refers to the fact that with SYMplus™ you can not only learn the theory, but you can also build a bridge to practical application. Learn more in the following practical tip video:

Follow KELLER.Software on YouTube to learn more:

https://www.youtube.com/CNCKELLERGmbH

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy – Training at Campus Handwerk GmbH

The KELLER.Academy was on the road again. This time at Campus Handwerk GmbH. There, trainers and teachers met for three days to have their knowledge topped up by our CNC expert Mr. Reckermann. In this course, we covered the complete program of SYMplus, from DIN/PAL, including driven tools and tilting, to graphic programming. On a DMG lathe on site with SIEMENS control, one of the programs was produced during the training. You can see the manufacturing process in the video.

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Practical Tip: Clever Cutting and Reclamping – In Video format

Cut a turned part to be machined on both sides from the bar and at the same time programme the second machining side. If the length of the blank is defined to such an extent that at the end, there is enough material to “cut” out of the protective zone for the chuck or the clamping jaws. However, if you proceed as described, after the “cutting off” step it would result in the half-finished workpiece falling in the simulation as in reality in the chip tray or a part catcher. Afterwards, the geometry is no longer available in the working plan for further machining.

But what is the solution then? The practical tip gives you the answer to this question.

Please follow our Youtube channel to watch the latest videos:

https://www.youtube.com/channel/UCyBovavGxzuJmrm1OXZuErw

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Newsletter February 2022

Learn new things faster and more effectively

It is no secret that learning is increasingly taking place on the Internet.

Videos are particularly popular. Videos increase the clarity of a topic through their visual presentation and, because our brains remember images better than texts, help us retain information in our heads for longer.

That’s why we at KELLER.Software have been running a YouTube channel for a few years now, covering topics such as:

How does the machining of Grooves work?> https://www.youtube.com/watch?v=SqqflAwVSeE

How to setup vocabulary tests and multiple choice tasks using SYMplus™ software?> https://www.youtube.com/watch?v=D5FngKoU1Qo&t=4s

How to compare production strategies effortlessly with each other using SYMplus™ software?> https://www.youtube.com/watch?v=wSeaABYL7wg&t=3s

There is something for everyone. No matter whether you are just taking your first steps as an apprentice or would like to further your education as an experienced person.

Click here to go to the KELLER.Software YouTube channel > https://www.youtube.com/c/CNCKELLERGmbH

Practical Tip: From PAL Programming to chips

The phrase “From PAL programming to chips” refers to the fact that with SYMplus™ you can not only learn the theory, but you can also build a bridge to practical application.

To learn more about this Tip of the Month, please click on the picture.

Much more from KELLER.Software…

Upcoming Training Sessions:

10.-11. Mar. 2022: Driven tools, plane swing and reform PAL2020

17.-18. Mar. 2022: Basics of graphic programming (CAD/CAM) with SYMplus™.

Further Information> https://cnc-keller.com/keller-academy/

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!