SYMplus™ Update 66

Good News for all SYMplus™ users!

Update 66 of our SYMplus™ CNC software is now available for you to install. With a variety of improvements and optimised functions, we want to ensure that you can work with the software more smoothly than ever before.

- Find out more about the new features here: symplus-support/new-features-optimizations/

- And for anyone wondering how to update SYMplus™, here’s a detailed guide on our support page: support-en.cnc-keller.de/entries/000154/

Thank you for your trust in us and our software.

– Your KELLER.Software team

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Steep Cone Tool Holder with integrated Pull Stud (CNC Turning)

- Take a look: https://youtu.be/ao6tjuqGYbM

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 12 from Christiani’s “Collection of tasks in CNC turning technology according to PAL2020” could look like in reality.

This task includes:

- Radial Grooving Cycle G86

- Circumferential Groove

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER at the NORTEC Tradefair (Throwback 2008)

In the year 2008, KELLER was present at the NORTEC Tradefair for production in Hamburg, North Germany along with HAAS and presented latest innovations and solutions to trade fair visitors.

The photo shows our head of sales, Mr. Reckermann talking to a HAAS employee near one of the CNC machines.

Discover more about our history on our website: https://cnc-keller.com/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video: Final Exam Part 2 for Machinists, Summer 2024 (Turning)

Simulation of the IHK Final Exam (Exam conducted by Chamber of Industry & Commerce, Germany) Part 2 for Machinists, Summer 2024, CNC Turning is now available on YouTube:

- Watch the video: https://youtu.be/rMk0jaUg78w

In the Turning examination task this time, all machining operations had to be carried out with driven tools on chordal surfaces (G19 IP5). In particular, gaps in the cycle calls (G7x) had to be filled, where the candidates needed to understand the axes in the G19 plane (YZ). In contrast to milling, however, it was not necessary to program entire contour trains. Instead, they were required to determine individual coordinates for the “center tolerance” and ISO fits. There were further gaps for recesses, an internal recess and jump addresses in program part repetitions.

- Interested to see more videos like this? Click on this link to visit us: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Newsletter June 2024

The exams are finally over and the summer vacation is just around the corner. But before you go fully into vacation mode, let’s take a look back at the exams – especially at the tasks given. What content was covered? What tricky challenges had to be mastered this year?Bye-bye exam stress, Hello summer!

Milling:

There were no major surprises in the milling exam. Of course, it was necessary to master the functions for switching the radius correction on and off and to apply the commands for soft approach and departure that have been changed since 2020.

In addition, contour points had to be read from the drawing and starting point coordinates had to be subtracted from the centre point coordinates, which were always dimensioned absolutely, to calculate I and J. Two fitting dimensions had to be determined, a rotational speed had to be calculated and some gaps in the cycle for thread milling (G88) and tapping (G84) had to be filled – similar to the previous winter exam.

You can view the Milling test task as a 3D simulation here: https://youtu.be/qdoeAGjywiE

Turning:

In the Turning examination task this time, all machining operations had to be carried out with driven tools on chordal surfaces (G19 IP5). In particular, gaps in the cycle calls (G7x) had to be filled, where the candidates needed to understand the axes in the G19 plane (YZ).

In contrast to milling, however, it was not necessary to program entire contour trains. Instead, they were required to determine individual coordinates for the “center tolerance” and ISO fits. There were further gaps for recesses, an internal recess and jump addresses in program part repetitions.

You can view the Turning test task as a 3D simulation here: https://youtu.be/rMk0jaUg78w

When will the next Software-Update be released?

We know that many schools use the summer vacation to update their IT infrastructure, so we’re working hard behind the scenes to get the latest SYMplus update ready for you to download before the summer vacation! As soon as it is available, you will be informed via this newsletter, our social media channels (Facebook, LinkedIn, Instagram) or on our website.

As soon as the update has been released, you can read about all the new features here: cnc-keller.com/symplus-support/new-features-optimizations/

Wish you a relaxing Summer.

– Your KELLER.Software Team

Next Appointments in the KELLER.Academy:

Basics of graphical programming (CAD/CAM) with SYMplus™

- 25.-26. July 2024

- 05.-06. September 2024

Basic DIN/PAL programming with SYMplus™

- 08.-09. August 2024

- 19.-20. September 2024

Driven tools, level swivel and reform PAL2020

- 11.-12. July 2024

- 22.-23. August 2024

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

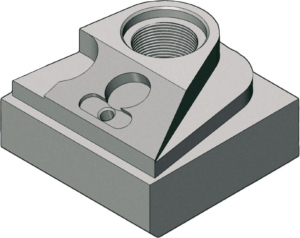

New video: Final Exam Part 2 for Machinists, Summer 2024 (Milling)

Simulation of the IHK Final Exam (Exam conducted by Chamber of Industry & Commerce, Germany) Part 2 for Machinists, Summer 2024, CNC Milling is now available on YouTube:

- Watch the video: https://youtu.be/qdoeAGjywiE

The milling exam task had no major surprises: Switching on and off functions of the radius correction and the commands for soft approach and departure that have been updated since 2020, had to be mastered. Reading contour points, calculating start point coordinates, determining two fitting dimensions, calculating rotation speed and filling in gaps in the cycle for thread milling (G88) and tapping (G84).

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

GKE + CAM – Graphical Programming (Throwback 1989)

Today we look back on our product “GKE + CAM”, the forerunner of our current CNC software SYMplus™! This tool revolutionised “graphical programming”. With clear pictograms, the most complex geometries could be captured and combined with the raw part in the work plan. Production strategies such as roughing and finishing were implemented directly in tool paths, without the need for G and M functions.

Well-known personalities like the one in the photo, Johannes Rau (then Minister-President of NRW, later Federal President), were highly impressed. On the right next to him are Mrs. and Mr. Keller.

Fun fact: Rau was born in Wuppertal and was even mayor of his home town from 1969 to 1970.

Discover more about our history on our website: https://cnc-keller.com/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Basic DIN/PAL programming with SYMplus™ (KELLLER.Academy)

Last week, the KELLER.Academy focused on DIN/PAL programming with SYMplus™.

Congratulations to Mr. Schneider from Wolfgang Loch GmbH & Co. KG, as well as Mr. Harmsen-Pawils from MIELE (Lehrte plant) and Mr. Möllinghoff from BZI Remscheid on their successful completion of the course! Thank you for a great time! We hope to welcome you back to Wuppertal soon.

Interested in developing your professional skills too? Browse through the courses offered by the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

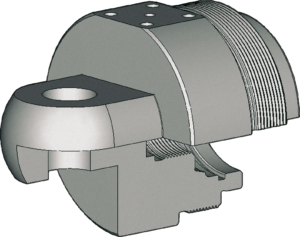

New video on YouTube: 2-sided CNC machining: radius correction, thread undercutting (DIN76), thread turning …

- Take a look: https://youtu.be/9cHl-NGoXf4

Using the 3D simulation of our SYMplus™ CNC software, we will show you how task 12 from Christiani’s “Collection of tasks in CNC turning technology according to PAL2020” could look like in reality.

This task includes:

- Drilling G84

- Internal roughing G81

- Finishing with radius correction (external and internal)

- Internal grooving

- Thread undercut DIN76

- Thread turning G31

- Interested to see it? Click on this link to watch the video: https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Bergisches Competence Center for CNC and PLC Technology (Throwback 2001)

In May 2001, the “Bergisches Competence Center for CNC and PLC Technology” was inaugurated at BZI Remscheid!

This marked a strong partnership between KELLER, SPINNER, SIEMENS, and BZI, which provided the facilities and infrastructure (and with whom we still maintain a close friendship to this day!).

Together, we introduced state-of-the-art CNC programming into various industries. Thanks to practical courses and innovative tools such as ShopMill and ShopTurn from SIEMENS, skilled workers quickly familiarised themselves with the then-new technology. But it wasn’t just professionals; students also had the opportunity to immerse themselves in the world of metal technology and create their own workpieces.

- In the group photo from left to right: Mr. Strackbein (BZI), Mr. Tödt (BZI), Mr. Spinner (SPINNER), Mr. Keller (KELLER), Mr. Gatti (SIEMENS).

- In the second photo, you can see Mr. Reckermann, our Head of Sales, leading a course on the opening day.

Discover more about our history on our website: https://cnc-keller.com/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!