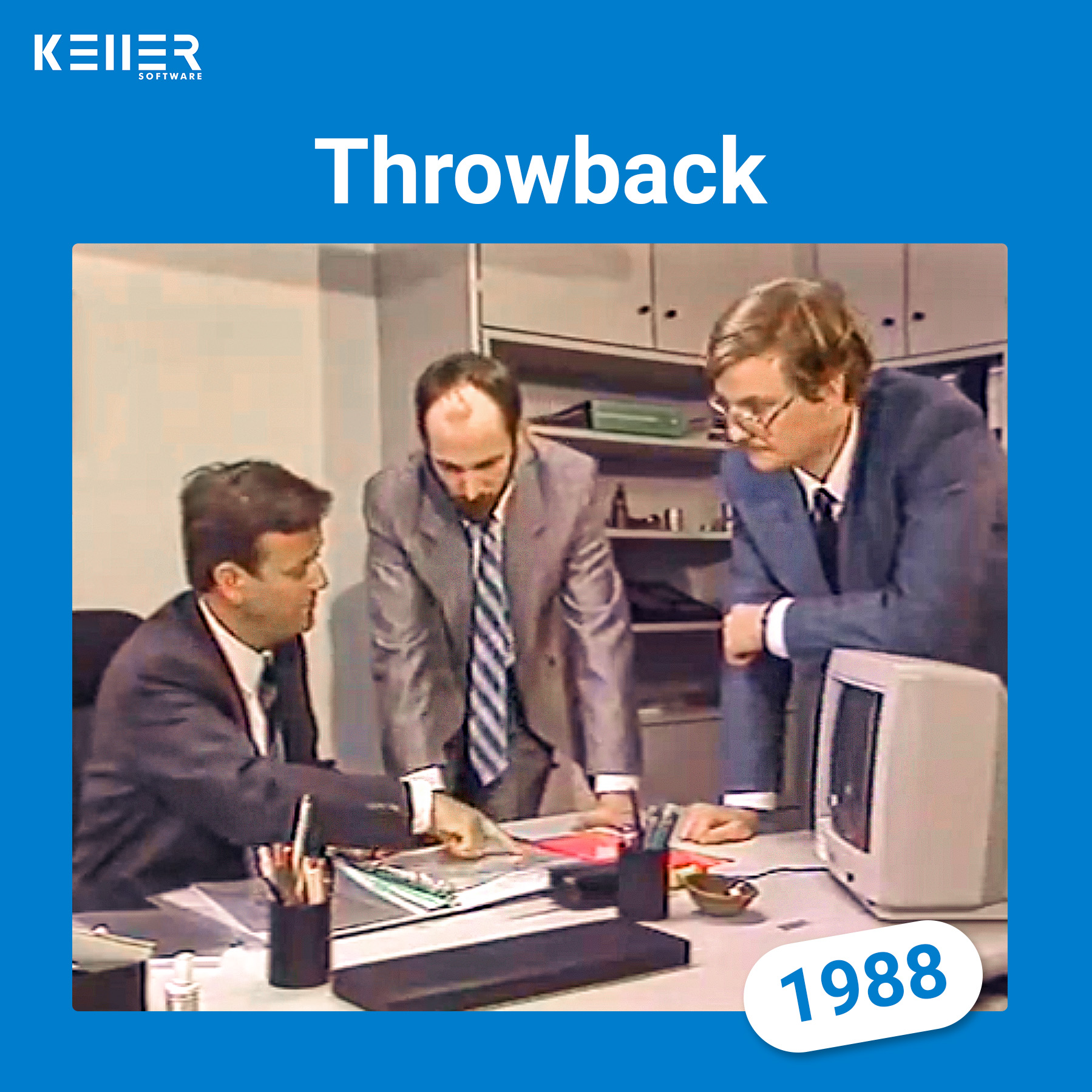

Throwback 1988 – Founder Mr. Keller plans the future of his company

Let’s rewind to the year 1988! In this photo, you can find our founder and former CEO, Mr. Siegfried Keller, on the left. Standing beside him (the man with the striped tie) is Mr. Puschner, the former authorised officer of the company. And on the far right of the image, casually propping himself against the monitor, is Mr. Klaus, CEO of the former Klaus Datentechnik in Wuppertal (who sadly passed away a few years ago). Collectively, they were shaping the future of R. & S. KELLER GmbH (now CNC KELLER GmbH).

During this time, our product “GKE + CAM” also hit the market, capturing significant attention in the CNC world. Even the industry giant SIEMENS was impressed, marking the beginning of a significant partnership.

Discover more about our history on our website: https://cnc-keller.de/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Spherical cutter in action

New “INSTANT CNC” Video!

We have once again simulated a challenging task using our SYMplus™ CNC software – this time, we’re tackling Exercise 8 from the Christiani booklet “Collection of tasks on CNC technology milling according to PAL2020”.

This exercise covers the Spherical cutter.

Just click the link below to watch the video: https://www.youtube.com/watch?v=vmK-RGzZlNE

Want to stay updated on all our videos and show us some support? Then make sure to subscribe (it’s free!) to the KELLER YouTube channel:

https://www.youtube.com/@CNCKELLERGmbH

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy – course: Basic DIN/PAL programming with SYMplus™

Last week, in a small yet highly motivated group at KELLER.Academy, we delved into the topic of ‘Basic DIN/PAL programming with SYMplus™’.

Both the participants from Kolping Bildung Dortmund and BBS Cuxhaven had limited exposure to CNC programming in Milling before. But that’s precisely why they came to us.

The result? A major success! The enthusiasm and commitment were truly remarkable. Congratulations on passing the KELLER.Academy course!

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

KELLER.Academy – CAD/CAM training with Miler CNC-Gravuren + Zerspanung

An absolutely awesome takeaway from our time at the KELLER.Academy last week: ‘Reduction Nipples.’ These little but highly practical components are experts at connecting different threads. And, of course, our instructor, Mr. Reckermann, along with our training guest, Mr. Miler (from Miler CNC-Gravuren + Zerspanung), programmed these workpieces on the spot using our CNC software SYMplus™. Perfectly aligned with the course theme ‘CAD/CAM.’

Fun fact: Embracing the philosophy of ‘you’re never too old to learn,’ Mr. Miler invested in personal training at the age of 77. What’s more, he spilled the beans that he’s gearing up to purchase a brand-new machine. Truly inspiring!

Click on the following link to learn more about the courses offered at the KELLER.Academy: https://cnc-keller.com/keller-academy/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Pockets/Contours/Drilling operations on 86 program lines with 9 different tools

A new “INSTANT CNC” Video is here!

We have once again simulated a challenging task using our SYMplus™ CNC software – this time, we’re tackling Exercise 7 from the Christiani booklet “Collection of tasks on CNC technology milling according to PAL2020”.

This exercise covers the “full program” to prepare for the test: pockets, contours, drilling operations mixed within 86 program lines using nine different tools.

Just click the link below to watch the video: https://www.youtube.com/watch?v=NvIPtUhMLPk

Want to stay updated on all our videos and show us some support? Then make sure to subscribe (it’s free!) to the KELLER YouTube channel:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

To all trainees we’re sending you the best wishes as you kick off your journey into the new training year!

To all trainees – whether you’re in your first, second, or third year – we’re sending you the best wishes as you kick off your journey into the new training year!

By the way, have you come across our SYMplus™ Student Version? It’s the one you can easily rent online for anywhere from 2 weeks up to 1 year! No subscriptions, just pay with PayPal or a similar method, and you’re ready to dive in!

The perfect learning software for all trainees, helping you dive into CNC basics as per DIN66025 and prepare effectively for the PAL exam:

- Interactive lessons with engaging images and videos

- PAL commands of CNC fundamentals

- Quiz mode to test under exam pressure

- A free CNC programming practice mode to fine-tune your skills

You can buy your license here: https://www.cleverbridge.com/858/purl-cnc-keller-Katalogeng

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

The KELLER support page

Experiencing difficulties? Have questions about SYMplus™? Reach out to our dedicated KELLER-Support! Here is the link: http://cnc-keller.yoursupport.de/cnc.en/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Inclined straight lines = crooked X/Y coordinates, centering/drilling on pitch circles

The next “INSTANT CNC” Video is now available on KELLER-YouTube Channel.

We have chosen another exercise (Exercise 6) from the Christiani booklet “Collection of CNC milling tasks according to PAL2020″ and simulated it with our CNC software SYMplus™. This time we are dealing with polar coordinates or ” crooked” Cartesian coordinates (G1 X Y, G3 X Y I J / R).

Click on this link to watch the video: https://www.youtube.com/watch?v=LsC7yy6lSr0

To never miss one of our videos, please subscribe to our YouTube channel:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Throwback 1983 – CNC machines

Time travel to the year 1983! Our founder, Mr. Keller, was working as a vocational school teacher in metal technology at the “Gewerbliche Schule II der Stadt Wuppertal” (now “Berufskolleg Werther Brücke”) in 1983. It was there that the foundations for NC theory and NC practice were laid in the late 70s.

The very first CNC machine at the school was a DECKEL-FP-2-NC milling machine (Refer to the picture). However, back then, there was no money to purchase a lathe machine. But Mr. Keller wasn’t discouraged! He went above and beyond to raise the necessary funds and managed to gather an impressive sum of 140,000 DM (equivalent to 154,216 €, adjusted for inflation) through donations from entrepreneurs in Wuppertal. And thus, the CNC lathe machine, a GILDEMEISTER NEF 400 (The last picture), was acquired.

Discover more about our history on our website: https://cnc-keller.de/history/

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

New video on YouTube: Zero Offset, Roughing/Finishing and Subroutine technology

A new “INSTANT CNC” Video is now available for you on our YouTube Channel!

In this latest video of this series, the 5th exercise from the Christiani booklet “A collection of exercises in CNC milling technology according to PAL2020” is simulated with the help of our CNC software SYMplus™. This task deals with zero offset, roughing/finishing and subroutine technology (G59, G22).

Click on this link to watch the video: https://www.youtube.com/watch?v=JIdNH0xffJ0

For the latest updates and videos, please subscribe to our YouTube Channel:

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!