Newsletter February 2022

Learn new things faster and more effectively

It is no secret that learning is increasingly taking place on the Internet.

Videos are particularly popular. Videos increase the clarity of a topic through their visual presentation and, because our brains remember images better than texts, help us retain information in our heads for longer.

That’s why we at KELLER.Software have been running a YouTube channel for a few years now, covering topics such as:

How does the machining of Grooves work?> https://www.youtube.com/watch?v=SqqflAwVSeE

How to setup vocabulary tests and multiple choice tasks using SYMplus™ software?> https://www.youtube.com/watch?v=D5FngKoU1Qo&t=4s

How to compare production strategies effortlessly with each other using SYMplus™ software?> https://www.youtube.com/watch?v=wSeaABYL7wg&t=3s

There is something for everyone. No matter whether you are just taking your first steps as an apprentice or would like to further your education as an experienced person.

Click here to go to the KELLER.Software YouTube channel > https://www.youtube.com/c/CNCKELLERGmbH

Practical Tip: From PAL Programming to chips

The phrase “From PAL programming to chips” refers to the fact that with SYMplus™ you can not only learn the theory, but you can also build a bridge to practical application.

To learn more about this Tip of the Month, please click on the picture.

Much more from KELLER.Software…

Upcoming Training Sessions:

10.-11. Mar. 2022: Driven tools, plane swing and reform PAL2020

17.-18. Mar. 2022: Basics of graphic programming (CAD/CAM) with SYMplus™.

Further Information> https://cnc-keller.com/keller-academy/

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

PRACTICAL TIP – From PAL Programming to chips

February 2022

The phrase “From PAL programming to chips” refers to the fact that with SYMplus™ you can not only learn the theory, but you can also build a bridge to practical application. Please note that whether you have a new machine with SIEMENS, HEIDENHAIN or HAAS or one from the 80s with a Dialog 4, EPL or CNC432 control, it always works the same way.

We will show you in the following practical tip how this works:

Step 1

Load the program you want to put on the machine into the PAL simulator and test it diligently using the simulation.

Step 2

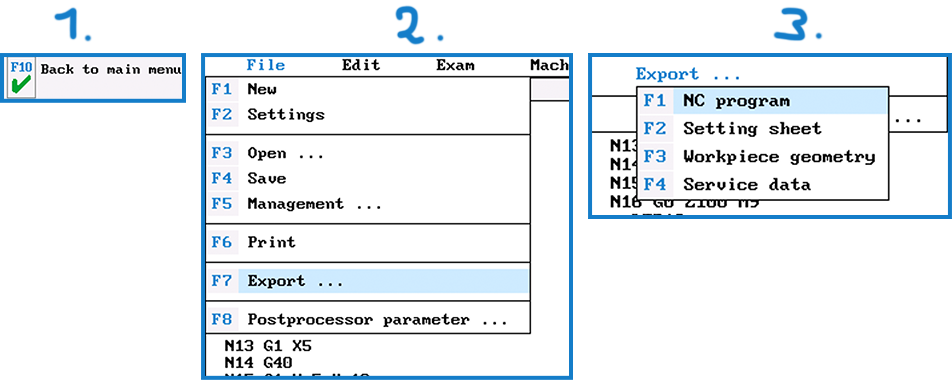

Now carry out the following steps 1, 2 and 3:

Step 3

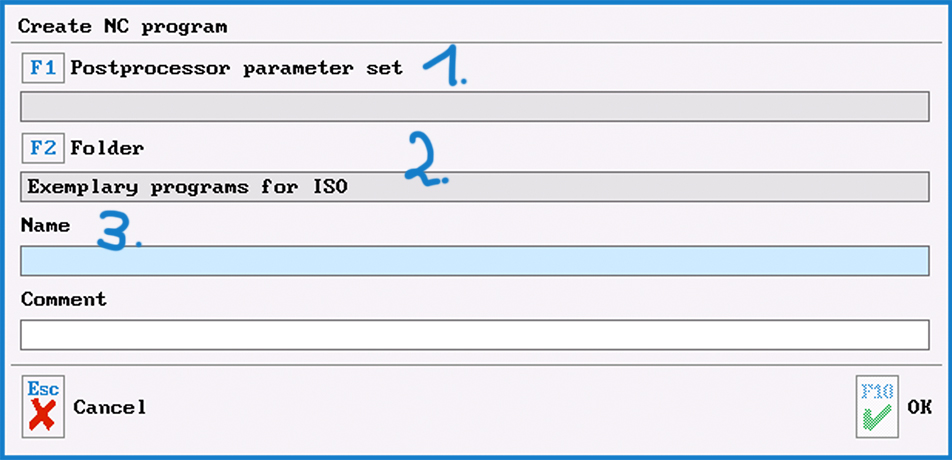

Generate NC program:

3.1.

Search for the parameter file of the desired control via F1 “Control parameters” and confirm the selection with F10.

3.2.

Use F2 “Folder” to select the location where you want to save the program ( for example, this could be on a hard disk or a USB stick)

3.3.

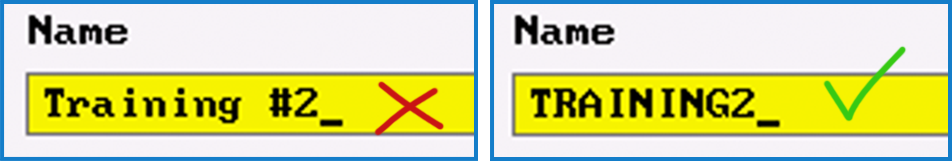

Please be aware that older controllers in particular only allow numbers and no letters in the “Name” field. Also, please refrain from using special characters and spaces.

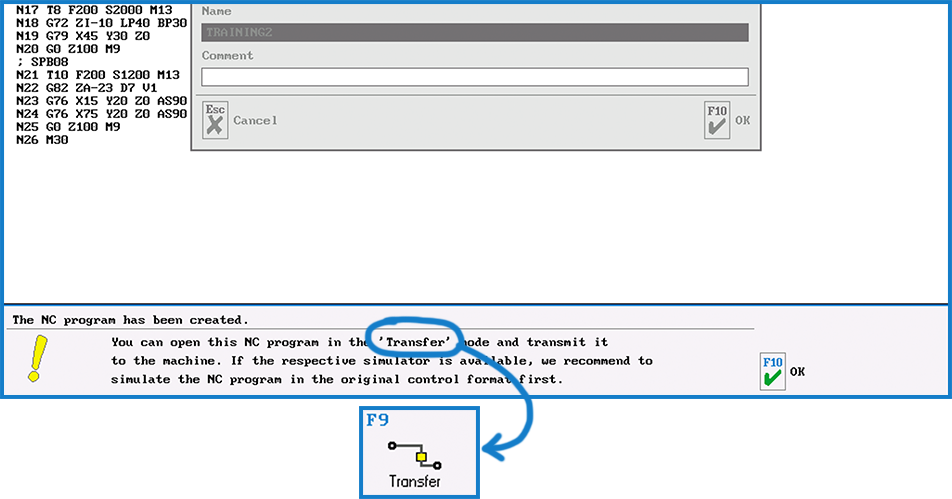

Step 4

The program must now be transferred to the machine. This can be done either via network, USB connection or “serially” using the “Transfer” mode of SYMplus™.

Step 5

Test the generated program again using the simulation graphic on the control. If any changes are necessary, feel free to contact us.

Step 6

When everything is running smoothly: Why not record your success with a photo or video and send it to us? We are always happy to receive such responses. We look forward to seeing your PAL programming practice workpieces on the machine!

Was this tip helpful? Let us know.

You will find more tips in the upcoming newsletters.

You have questions? Contact our experts using the contact form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Newsletter January 2022

Into the new year with good news.

KELLER.Software wishes you a Happy and Prosperous New Year 2022.

We at KELLER.Software, are also back from a week of company holidays, refreshed, relaxed and energized. We usually like to start our new year with good news. 2022 is also not different. The good news this year is that the free PAL student licenses that we offered to support students during the pandemic, to help them train from home, has been extended till 30.06.2022. Please note that you can only apply for these free licenses until 30.05.2022. We hope this small gesture from us helps support your students in their training.

In case you are a student/trainee in Germany and you haven’t applied for it yet, feel free to do it here > https://cnc-keller.de/symplus-erwerben/#simplus-fuer-zuhause

You probably already read on our social media channels that we are participating in the education exhibition in London, BETT UK 2022. Please note that the exhibition dates have been postponed from January to March 23 – 25, 2022 due to the current restrictions in London from the pandemic. Of course, this does not diminish our excitement. We are very much looking forward to spending three days immersed in inspiring content, networking and exchanging ideas with educators from all over the world.

More info on this can be found here: https://cnc-keller.com/aktuelles/bett-uk-2022-education-exhibition/

Once again KELLER.Software wishes you a successful 2022.

Much more from KELLER.Software…

Next appointments:

10.-11. Feb. 2022: Basics of graphical programming (CAD/CAM) with SYMplus™

24.-25. Feb. 2022: Basic DIN/PAL programming with SYMplus™

More info > https://cnc-keller.com/keller-academy/

Let us learn something new this new year. Head over to the KELLER.Software YouTube channel where you can learn all about SYMplus™ and watch other interesting CNC videos as well.

Stop by and leave a subscription to never miss any new videos > https://www.youtube.com/c/CNCKELLERGmbH

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Newsletter December 2021

Your 2021 with KELLER.Software.

The year 2021 was once again full of challenges, experiences and innovations. But before we wish each other “Merry Christmas and a good and successful year 2022”, December once again offers the opportunity to look back together into the last year:

And in December? The KELLER.Software team will be there for you as usual, so that you can get everything sorted before the end of the year.

Much more from KELLER.Software…

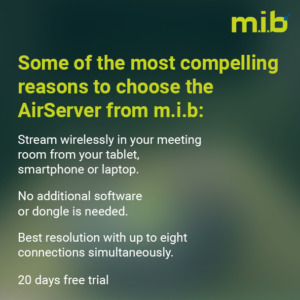

For more Information > https://www.mib-airserver.de

Next appointments:

In 2022, the doors of the KELLER.Academy will remain open for you. Keep an eye on our website for new schedules or contact us to book your next training.

More info > https://cnc-keller.com/keller-academy/

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Practical Tip: 3 steps to rotary-symmetric contour – In Video format

A pocket or an island contour is usually constructed from the starting point of the contour once around to the end point. In the case of a rotary-symmetrical contour, this would usually be unnecessarily time-consuming and, in part, hardly feasible anyway due to the dimensions. When programming in SYMplus™, you can achieve the complete contour in just three steps. Watch the video to find out how.

Please follow our Youtube channel to watch the latest videos:

https://www.youtube.com/channel/UCyBovavGxzuJmrm1OXZuErw

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Customer Review KNIPEX (Part 2)

Knipex has been using SYMplus CNC software for more than 15 years now in their training. In this video, hear directly from the Head of Technical Training at Knipex, Mr.Herkert, what makes KELLER their preferred CNC Software in training.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Customer review KNIPEX (Part 1)

Training more than 70 apprentices with different levels of knowledge is a big task.

Hear from Mr.Herkert, the head of technical training at the firm Knipex as he explains how KELLER has helped him through this challenge for many years as well as in times of Homeschooling since 2020.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

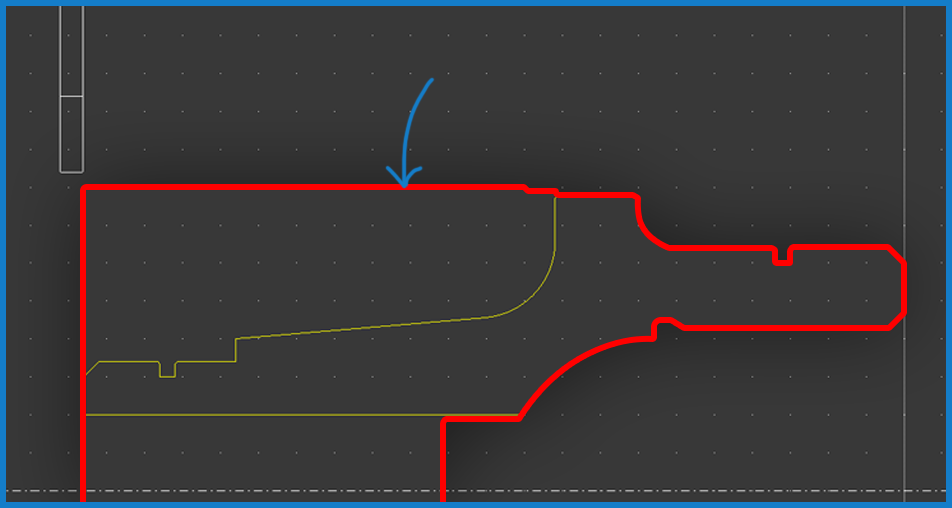

PRACTICAL TIP – Clever Cutting and Reclamping

October 2021

The plan was quite simple.

Cut a turned part to be machined on both sides from the bar and at the same time programme the second machining side. If the length of the blank is defined to such an extent that at the end, there is enough material to “cut” out of the protective zone for the chuck or the clamping jaws.

However, if you proceed as described, after the “cutting off” step it would result in the half-finished workpiece falling in the simulation as in reality the chip tray or a part catcher. Afterwards, the geometry is no longer available in the working plan for further machining.

But what is the solution then? The following practical tip gives you the answer:

Step 1:

Instead of giving the blank an excessive length, make it only slightly longer than the finished part and assign negative values to the outer and inner values of the protection zone (tool width of the parting line).

Step 2:

The half-machined workpiece (red lines) then remains in the routing and can be saved in this form via F1 “File” > F7 “Export” > F1 “Workpiece geometry”.

Step 3:

The new blank can then be used for a second working plan.

Step 4:

Under F4 “Clamping” the workpiece is first turned over. Special attention must then be paid to the input field “Shift Z”. In the example, -0.4 must be entered because, in addition to the stock allowance for the second side of 0.2 mm here, the “slug” left by the cutting radius of the parting-off tool must also be taken into account.

Step 5:

The last step is to determine the work steps as usual and as on the first page. Here you benefit from the so-called contour tracking of the software, which recognises where drilling and roughing has already been done from the first page. This becomes visible when creating the work steps by the correspondingly reduced red areas (here for the roughing cut inside).

Now it’s your turn.

Was this tip helpful? Let us know.

You will find more tips in the upcoming newsletters.

You have questions? Contact our experts using the contact form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Operating a CNC Machine using SYMplus™.

How to avoid an idle CNC machine?

Tricky production order and no solution? Schmidt Zerspanungstechnik GmbH had the same problem the other day …

The problem: The control system of their machine does not offer a suitable cycle for two counter-rotating 3-flute flat threads on a spreader roll (Ø152, length approx. 3m).

The solution: A macro in SYMplus™ that can rough and finish the threads with normal grooves in many small infeeds.

Do you have a similar case or something more challenging? Then spare your time and nerves and contact us today using the form below – the KELLER.Software team is ready to help you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Practical Tip: Vocabulary tests? Multiple choice tasks? This is how it works with SYMplus™ – In Video format

If you teach DIN/PAL programming using our SYMplus™ software, you are probably familiar with the “Teacher” mode of operation, which allows you to perform gap-filling tasks in the style of the written IHK(Chamber of Industry and Commerce, Germany) final examinations. What you may not know, however, is that this operating mode gives you many more options than simply using an NC program as a basis.

To learn how to set up vocabulary tests and multiple choice tasks on SYMplus™, watch this video.

To watch more videos like this, please follow our Youtube channel:

https://www.youtube.com/watch?v=D5FngKoU1Qo&t=42s

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!