Practical Tip: How to organise Postprocessors – In Video format

SYMplus™ provides a list of around 50 Postprocessors. In reality, you will hardly ever need all of them. Mostly you work with one or a few. So selecting the right postprocessor can prove to be a nuisance with such a large list. Here is a tip that can help you organise those Postprocessors efficiently: Create a second folder for postprocessor parameter sets, and copy the postprocessors you currently need into this folder. That’s it.

In this practical tip, you will see how this works:

Follow KELLER.Software on YouTube to learn more:

https://www.youtube.com/CNCKELLERGmbH

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Newsletter December 2022

6 steps to an organised Postprocessor list.

SYMplus™ provides a list of around 50 Postprocessors. In reality, you will hardly ever need all of them. Mostly you work with one or a few. So selecting the right postprocessor can prove to be a nuisance with such a large list. Here is a tip that can help you organise those Postprocessors efficiently: Create a second folder for postprocessor parameter sets, and copy the postprocessors you currently need into this folder. That’s it.

Here it goes:

Step 1: Open the “Work plan” operating mode (alternatively also “PAL simulator” or “Simulator”).

Step 2: Select “F1 File” > “F5 Management” > “F4 Postprocessor Parameter”.

Step 3: Mark the file(s) relevant to you and …

Click here to read the full version of the Practical Tip >

SYMplus™ Update 63 is now available to all customers with plusCARE™ and includes new features as well as great improvements.

Scale the font size in the editor of the simulators to 200% by default (e.g. for the beamer image of the teacher’s computer)

When creating PAL gap-filling tasks, store individual instructions for each gap in the text

Receive the new simulators for the SINUMERIK 808D control system

The exchange of revolver stations and individual allowance presettings for roughing, facing and grooving in turning operation was never so easy

In addition, many detailed improvements in the simulators for PAL2020, SIEMENS 810D/840D and HEIDENHAIN allow for more effective work. The use of mobile licenses and the sources for the creation of individual macro work steps (by customer order) have also been improved. Other sample programs have been revised according to PAL2020 (for new installation as part of the user data).

More information about Update >

Lastly, we want to pause and look back at the past year.

It was great to see that many events and meetings took place this year. It started with the BETT UK education fair in London in March and ended with the BZI Remscheid open day last month.

The fact that face-to-face meetings were more feasible again than in the past two years was also evident at the KELLER.Academy: close to 40 guests came to the Academy courses this year (in comparison: there were less than twenty in 2021). In addition, the KELLER.Academy celebrated its fifth anniversary and held (virtual) training courses in Pakistan and Mexico, both of which are far away. In September, we published the new “SYMplus™ license via the Internet”, with which you now only need one KELLER ID to let several users work with SYMplus™. And in October, a new edition of the workbooks was also published.

Look out for more new improvements next year!

Missed new developments? Check out our website at KELLER.News for all the important information including newsletters, announcements and more.

KELLER.News >

The KELLER.Software team wishes you a pleasant Advent season and relaxing holidays.

– Your KELLER.Software Team

Much more from KELLER.Software …

Next Appointments:

12. – 13. January 2023: Basic graphic programming (CAD/CAM) with SYMplus™

26. – 27. January 2023: Basic DIN/PAL programming with SYMplus™

New on YouTube: With the PAL2020 reform, some commands in the PAL encoding have been changed. As a result, programs written according to PAL2008 or PAL 2012 no longer run and lead to error messages. With this practical tip, you can easily rewrite your programs.

Watch now on YouTube >

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

PRACTICAL TIP – How to organise Postprocessors

December 2022

SYMplus™ provides a list of around 50 Postprocessors. In reality, you will hardly ever need all of them. Mostly you work with one or a few. So selecting the right postprocessor can prove to be a nuisance with such a large list. Here is a tip that can help you organise those Postprocessors efficiently: Create a second folder for postprocessor parameter sets, and copy the postprocessors you currently need into this folder. That’s it.

Here it goes:

Step 1:

Open the “Work plan” operating mode (alternatively also “PAL simulator” or “Simulator”).

Step 2:

Select “F1 File” > “F5 Management” > “F4 Postprocessor Parameter”.

Step 3:

Mark the file(s) relevant to you and add them to your personal selection list with “F5 Add”. The selected files are then each marked with a black triangle/arrow.

Step 4:

Then select “F2 Copy” and choose the destination folder from the list. Confirm your selection with “F10”. If you don’t have a folder yet, create one by clicking “F2 Add …” or ‘link’ to an already existing one. In our example, the new folder is called “MY_PPs” and is a subfolder of the default folder “PARAM-SA”.

Step 5:

Finally, enter the name under which the folder should appear in the “SYMplus™ File Management” in the future (for example: “My Post Processors”) and confirm with 2x “F10”.

Now you can select your newly created folder from the folder list. Click on “F10” to open the folder. Subsequently, you can exit the parameter set management with “Esc” or “F10”.

We hope we could help you with this tip. For more practical tips, visit KELLER.News on our website or the KELLER YouTube channel.

You will find more tips in the upcoming newsletters.

You have questions? Contact our experts using the contact form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Practical Tip: Rewrite old PAL programs for the PAL2020 – In Video format

With the PAL2020 reform, some of the commands in the PAL coding were changed. The commands were changed so that programs written after PAL2008 or PAL 2012 will no longer run and lead to any error messages in the newer PAL2020 simulators (or PAL2020 C/Y or PAL2020 3+2). This means that you have to rewrite the program blocks almost completely – and that takes time.

A faster way to do this is to use the “Find/Replace” trick:

Follow KELLER.Software on YouTube:

https://www.youtube.com/CNCKELLERGmbH

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

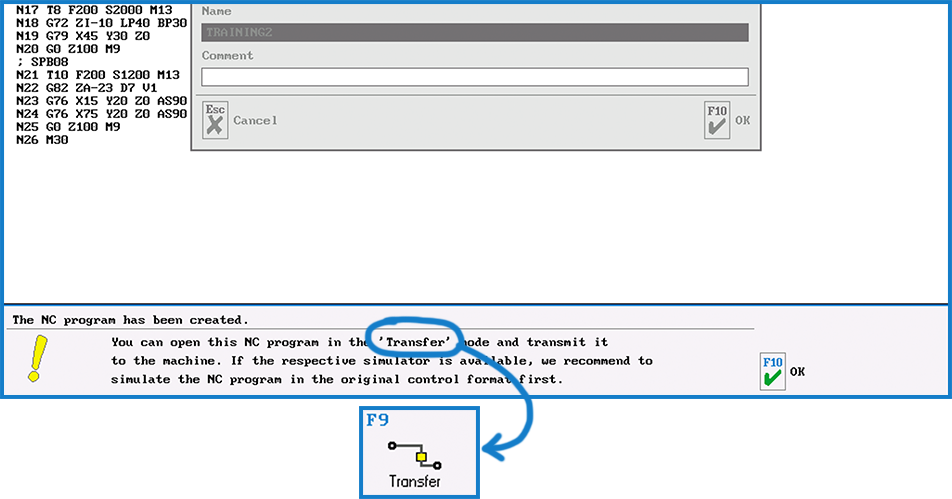

Practical Tip: From PAL programming to chips – In Video format

The phrase “From PAL programming to chips” refers to the fact that with SYMplus™ you can not only learn the theory, but you can also build a bridge to practical application. Learn more in the following practical tip video:

Follow KELLER.Software on YouTube to learn more:

https://www.youtube.com/CNCKELLERGmbH

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

PRACTICAL TIP – Rewrite old PAL programs for the PAL2020

September 2022

With the PAL2020 reform, some of the commands in the PAL coding were changed. The commands were changed so that programs written after PAL2008 or PAL2012 will no longer run and lead to any error messages in the newer PAL2020 simulators (or PAL2020 C/Y or PAL2020 3+2). This means that you have to rewrite the program blocks almost completely – and that takes time.

A faster way to do this is to use the “Find/Replace” trick:

This trick works when “translating” PAL2008 or PAL2012 commands to PAL2020, because there is a simple mapping between old and new here. Below, we will briefly touch on how you can rewrite the cycles more easily. You need this, for example, for the piercing cycles in turning, which are still called G86 or G88, but have many new or changed cycles.

Step 1

Open the program, which you have already programmed in an older PAL coding, in the “PAL2020” mode. You will then get the following message: “The NC program is faulty!” Delete this message by pressing “F10”. The last block that does not correspond to the PAL2020 coding is now marked in the editor. In the example (exercise program “LAGER3” from the workbook “Plane Swivel”): “N65 G17 CR180 AR90”. Here (and in many other places in the program) G17 must be replaced by G15.

Step 2

Now select the “Search/Replace” function using “F1” and enter “G17” in the “Search for” field and “G15” in the “Replace with” field:

Click on “Replace All” to replace “G17” with “G15” in the entire document. Finally, accept this edit with “F10”.

Step 3

Subsequently, in our example, the line “N45 G48 G40 R10 Z0” is marked as incorrect, because after PAL2020 the commands for tangential approach and departure have also changed. Replace them according to the same principle: “G48 G40 R” becomes “G40 G46 RR”. And then “G41 G45 D” = “G41 G45 DL”.

Step 4

For the training program “LAGER3” all necessary replacements are done with it, and you can use “F7 Editor” to switch back to the “guided mode”. There you can simulate the program using “F9” and finally save the changed program with for example the name extension “2020”.

A complete table with a comparison between “PAL2008/PAL2012” and “PAL2020” (as of summer 2022) can be found at the very bottom of this post.

Rewrite Cycles:

This is not quite as simple as the PAL commands. But with this little trick, you will surely save some effort:

Step 1

Start by commenting out the “old” cycle blocks in the editor. Then program the cycle blocks again in the guided mode (“F7 Editor”). Note that commenting out changes the line numbering (which affects jumps with G23), since pure comment lines have no line numbers. To avoid this, write the previous cycle as a comment after a regular (innocuous) NC block. This will then look for example like this:

N28 M1 ; G86 X60 Z-55 ET54 EB6 RO-0.5

Step 2

After you have changed the cycle set, just delete this comment again.

To learn more practical tips, please visit KELLER.News on our website or visit the KELLER YouTube channel KELLER-YouTube-Kanal.

| PAL2008/PAL2012 | PAL2020 | Meaning | Where is it found? |

| G41 G45 D | G41 G45 DL | Linear tangential approach | Milling and Turning with driven tools |

| G42 G45 D | G42 G45 DL | Linear tangential approach | Milling and Turning with driven tools |

| G40 G46 D | G40 G45 DL | Linear tangential departure | Milling and Turning with driven tools |

| G41 G47 R | G41 G46 RR | Tangential approach on a quarter circle | Milling and Turning with driven tools |

| G42 G47 R | G42 G46 RR | Tangential approach on a quarter circle | Milling and Turning with driven tools |

| G48 G40 R | G40 G46 RR | Tangential departure on a quarter circle | Milling and Turning with driven toolsn |

| G17 | G15 | Svivelling and Resetting the machining level | Milling Level selection |

| G17 | G15 G17 IP3 | Level selection face end with virtual Y axis | Turning with driven tools |

| G17 C | G15 G17 IP0 | Level selection face end with polar coordinates | Turning with driven tools |

| G17 Y C | G15 G17 IP5 CM | Level selection face end with real Y axis | Turning with driven tools |

| G18 | G15 G18 TURN | Level selection for Turning | Drehen mit angetr. Werkzeugen |

| G19 X | G15 G19 IP1 DM | Level selection surface area with virtual Y axis | Turning with driven tools |

| G19 C | G15 G17 IP0 | Level selection surface area with polar coordinates | Turning with driven tools |

| G19 Y X | G15 G17 IP5 DM | Level selection chord area with real Y Axis | Turning with driven tools |

| G86 | M1 ; G86 | Radial recessing cycle | Turning, not automatically “translatable”, therefore commented out here with M1 ;. The cycle must then be reprogrammed. |

| G88 | M1 ; G86 | Axial recessing cycle | Turning, not automatically “translatable”, therefore commented out here with M1 ;. The cycle must then be reprogrammed. |

You will find more tips in the upcoming newsletters.

You have questions? Contact our experts using the contact form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Practical Tip: Clever Cutting and Reclamping – In Video format

Cut a turned part to be machined on both sides from the bar and at the same time programme the second machining side. If the length of the blank is defined to such an extent that at the end, there is enough material to “cut” out of the protective zone for the chuck or the clamping jaws. However, if you proceed as described, after the “cutting off” step it would result in the half-finished workpiece falling in the simulation as in reality in the chip tray or a part catcher. Afterwards, the geometry is no longer available in the working plan for further machining.

But what is the solution then? The practical tip gives you the answer to this question.

Please follow our Youtube channel to watch the latest videos:

https://www.youtube.com/channel/UCyBovavGxzuJmrm1OXZuErw

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Newsletter February 2022

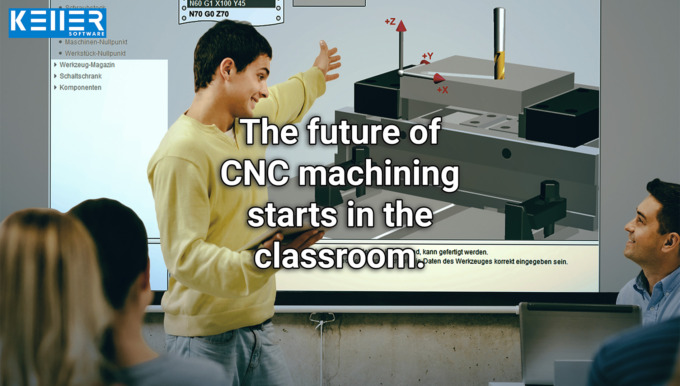

Learn new things faster and more effectively

It is no secret that learning is increasingly taking place on the Internet.

Videos are particularly popular. Videos increase the clarity of a topic through their visual presentation and, because our brains remember images better than texts, help us retain information in our heads for longer.

That’s why we at KELLER.Software have been running a YouTube channel for a few years now, covering topics such as:

How does the machining of Grooves work?> https://www.youtube.com/watch?v=SqqflAwVSeE

How to setup vocabulary tests and multiple choice tasks using SYMplus™ software?> https://www.youtube.com/watch?v=D5FngKoU1Qo&t=4s

How to compare production strategies effortlessly with each other using SYMplus™ software?> https://www.youtube.com/watch?v=wSeaABYL7wg&t=3s

There is something for everyone. No matter whether you are just taking your first steps as an apprentice or would like to further your education as an experienced person.

Click here to go to the KELLER.Software YouTube channel > https://www.youtube.com/c/CNCKELLERGmbH

Practical Tip: From PAL Programming to chips

The phrase “From PAL programming to chips” refers to the fact that with SYMplus™ you can not only learn the theory, but you can also build a bridge to practical application.

To learn more about this Tip of the Month, please click on the picture.

Much more from KELLER.Software…

Upcoming Training Sessions:

10.-11. Mar. 2022: Driven tools, plane swing and reform PAL2020

17.-18. Mar. 2022: Basics of graphic programming (CAD/CAM) with SYMplus™.

Further Information> https://cnc-keller.com/keller-academy/

To subscribe to our monthly newsletter, please use the form below. Thank you.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

PRACTICAL TIP – From PAL Programming to chips

February 2022

The phrase “From PAL programming to chips” refers to the fact that with SYMplus™ you can not only learn the theory, but you can also build a bridge to practical application. Please note that whether you have a new machine with SIEMENS, HEIDENHAIN or HAAS or one from the 80s with a Dialog 4, EPL or CNC432 control, it always works the same way.

We will show you in the following practical tip how this works:

Step 1

Load the program you want to put on the machine into the PAL simulator and test it diligently using the simulation.

Step 2

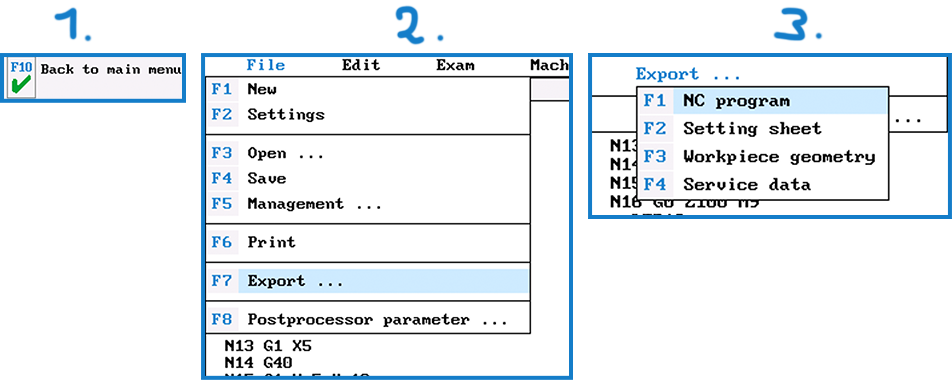

Now carry out the following steps 1, 2 and 3:

Step 3

Generate NC program:

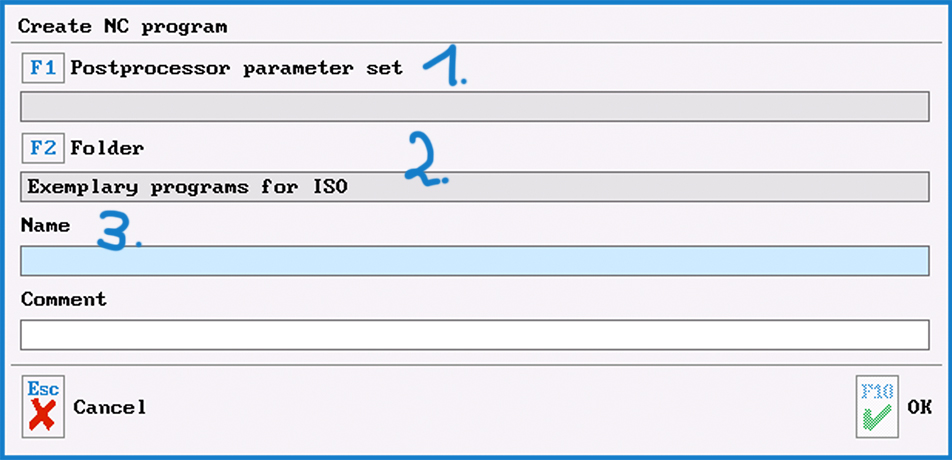

3.1.

Search for the parameter file of the desired control via F1 “Control parameters” and confirm the selection with F10.

3.2.

Use F2 “Folder” to select the location where you want to save the program ( for example, this could be on a hard disk or a USB stick)

3.3.

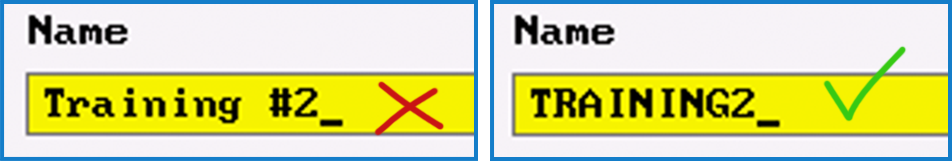

Please be aware that older controllers in particular only allow numbers and no letters in the “Name” field. Also, please refrain from using special characters and spaces.

Step 4

The program must now be transferred to the machine. This can be done either via network, USB connection or “serially” using the “Transfer” mode of SYMplus™.

Step 5

Test the generated program again using the simulation graphic on the control. If any changes are necessary, feel free to contact us.

Step 6

When everything is running smoothly: Why not record your success with a photo or video and send it to us? We are always happy to receive such responses. We look forward to seeing your PAL programming practice workpieces on the machine!

Was this tip helpful? Let us know.

You will find more tips in the upcoming newsletters.

You have questions? Contact our experts using the contact form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!

This might also be of interest to you

Practical Tip: 3 steps to rotary-symmetric contour – In Video format

A pocket or an island contour is usually constructed from the starting point of the contour once around to the end point. In the case of a rotary-symmetrical contour, this would usually be unnecessarily time-consuming and, in part, hardly feasible anyway due to the dimensions. When programming in SYMplus™, you can achieve the complete contour in just three steps. Watch the video to find out how.

Please follow our Youtube channel to watch the latest videos:

https://www.youtube.com/channel/UCyBovavGxzuJmrm1OXZuErw

For more tips, keep an eye out for our upcoming newsletters.

You have questions? Please feel free to contact our experts using the form below.

Do you have any questions?

Our experts are at your disposal. We look forward to your inquiry!